Environment-friendly efficient copper mine combination leaching device with reverse-cone sieve disc

An anti-cone sieve disc, green and environmental protection technology, applied in the direction of improving process efficiency, can solve the problems of insufficient air blowing, slow copper sulfide compound leaching, easy leakage of ammonia, etc. High efficiency of compound leaching, automatic and convenient replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with accompanying drawing, the present invention is described in further detail.

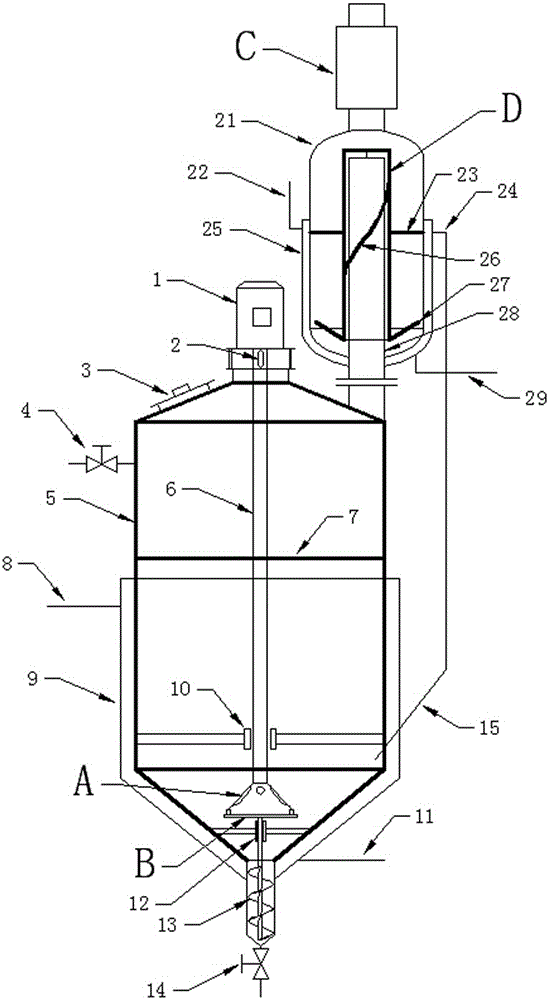

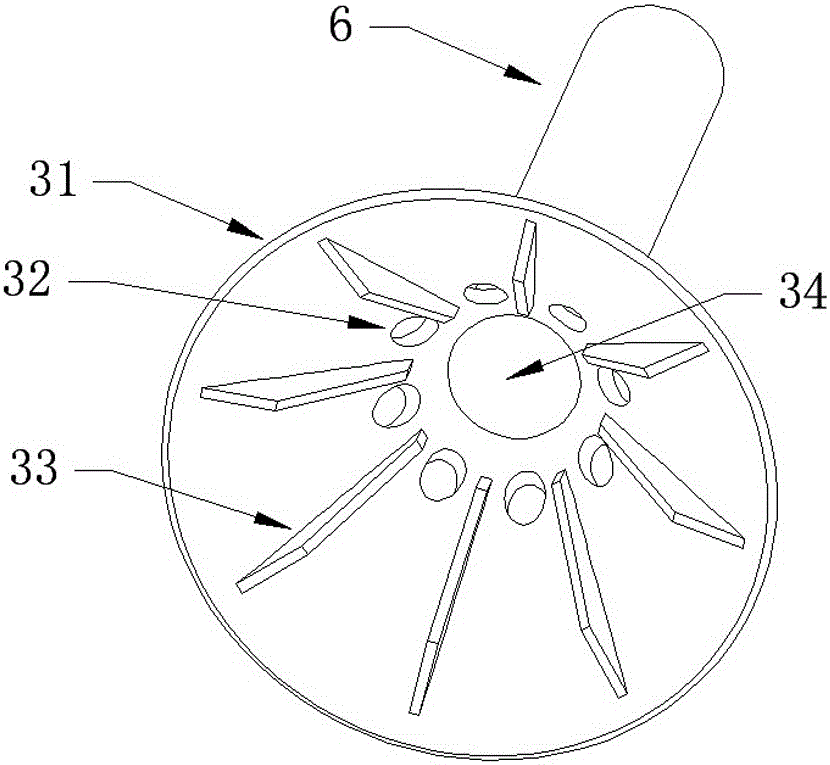

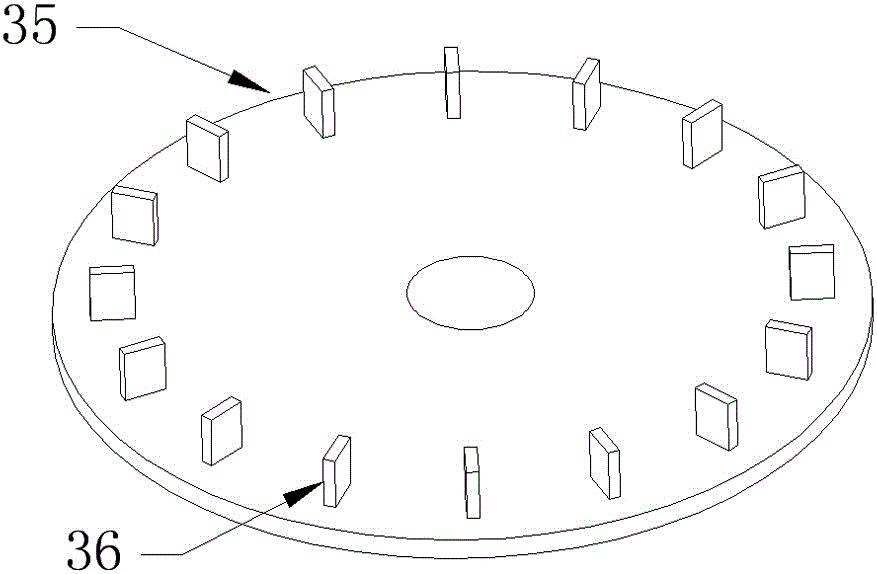

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The shown anti-cone sieve dish green environment-friendly copper ore high-efficiency compound leaching device includes a compound leaching barrel 5 and a tail gas purifier 21, and the intermediate pipe 28 of the compound leaching barrel 5 and the tail gas purifier 21 is detachably connected through a flange, and the tail gas purifier 21 is connected back to the compound leaching barrel 5 through the overflow pipe 24 and the liquid return inclined pipe 15; Inserted into the compound leaching barrel 5, the cone cover 31 is provided with blades 33 and liquid inlet holes 32, the upper part of the hollow shaft 6 has air inlets 2 uniformly distributed around the shaft circumference, and the lower part of the hollow shaft 6 has a shaft sleeve 10 for dynamic positioning and Stable support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com