Method for improving single-face TPU compound fabric flatness

A composite fabric and flatness technology, applied in the direction of fabric surface trimming, heating/cooling fabric, textile material processing, etc., can solve the problems of easy bending, difficult to operate in the next process, etc., and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

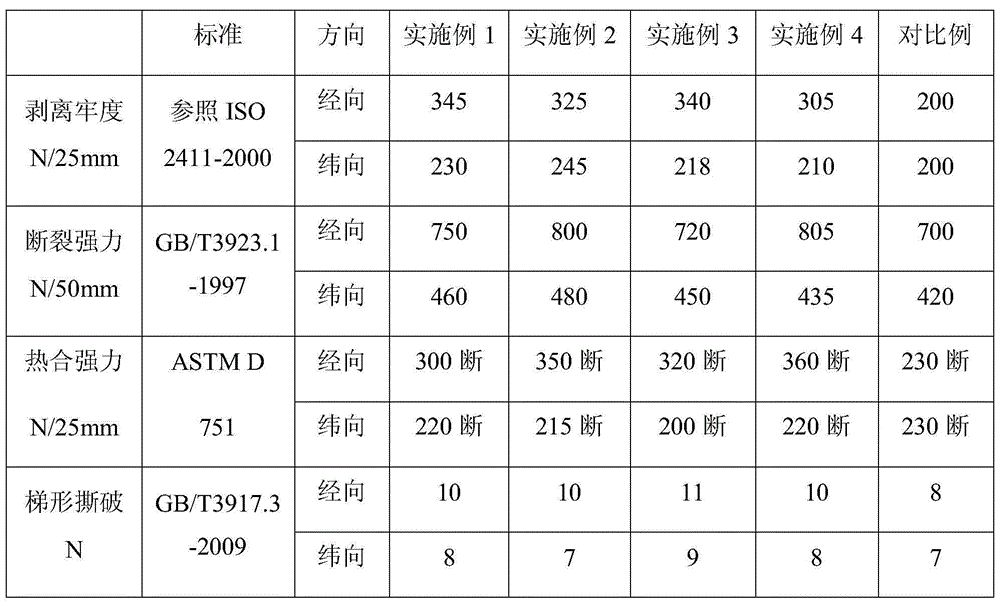

Examples

Embodiment 1

[0017] A method for improving the flatness of a single-sided TPU composite fabric mainly includes adding the following steps between the priming step and the TPU film-coating step in the production process of the TPU composite fabric:

[0018] Step (1), roll-forming process: roll the coated fabric obtained after priming on the shaft, the number of meters in the roll is 1000 meters, and the diameter of the roll is determined according to the thickness of the fabric. The rolls of fabric are then placed on the unwinding frame and pushed into the curing chamber.

[0019] Step (2), ripening treatment: place a humidifier in the ripening chamber, the power can be determined according to the size of the ripening chamber. Turn on the humidifier to pre-humidify the coated fabric. Indoor temperature: room temperature. Indoor humidity: 30% RH. Curing time: 24h.

[0020] Step (3), pre-treatment of TPU coating: After the machine is set up, before starting the coating, add water to the h...

Embodiment 2

[0022] A method for improving the flatness of a single-sided TPU composite fabric mainly includes adding the following steps between the priming step and the TPU film-coating step in the production process of the TPU composite fabric:

[0023] Step (1), roll-forming process: roll the coated fabric obtained after priming on the shaft, the number of rolls is 5000 meters, and the diameter of the roll is determined according to the thickness of the fabric. The rolls of fabric are then placed on the unwinding frame and pushed into the curing chamber.

[0024] Step (2), ripening treatment: place a humidifier in the ripening chamber, the power can be determined according to the size of the ripening chamber. Turn on the humidifier to pre-humidify the coated fabric. Indoor temperature: room temperature. Indoor humidity: 90% RH. Curing time: 24h.

[0025] Step (3), pre-treatment of TPU coating: After the machine is set up, before starting the coating, add water to the humidifier to ...

Embodiment 3

[0027] A method for improving the flatness of a single-sided TPU composite fabric mainly includes adding the following steps between the priming step and the TPU film-coating step in the production process of the TPU composite fabric:

[0028] Step (1), roll-forming process: roll the coated fabric obtained after priming on a shaft, with a roll diameter of 50 cm. The rolls of fabric are then placed on the unwinding frame and pushed into the curing chamber.

[0029] Step (2), ripening treatment: place a humidifier in the ripening chamber, the power can be determined according to the size of the ripening chamber. Turn on the humidifier to pre-humidify the coated fabric. Indoor temperature: room temperature. Indoor humidity: 50% RH. Curing time: 24h.

[0030] Step (3), pre-treatment of TPU coating: After the machine is set up, before starting the coating, add water to the humidifier to ensure the normal operation of the humidifier during the production process, adjust the humi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com