Device and method used for manufacturing high precision low loss optical fiber Y-branch splitter

A high-precision, low-loss technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of optical energy loss, optical energy loss, insufficient coupling of optical fiber links, etc., to achieve high accuracy and the same coupling degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

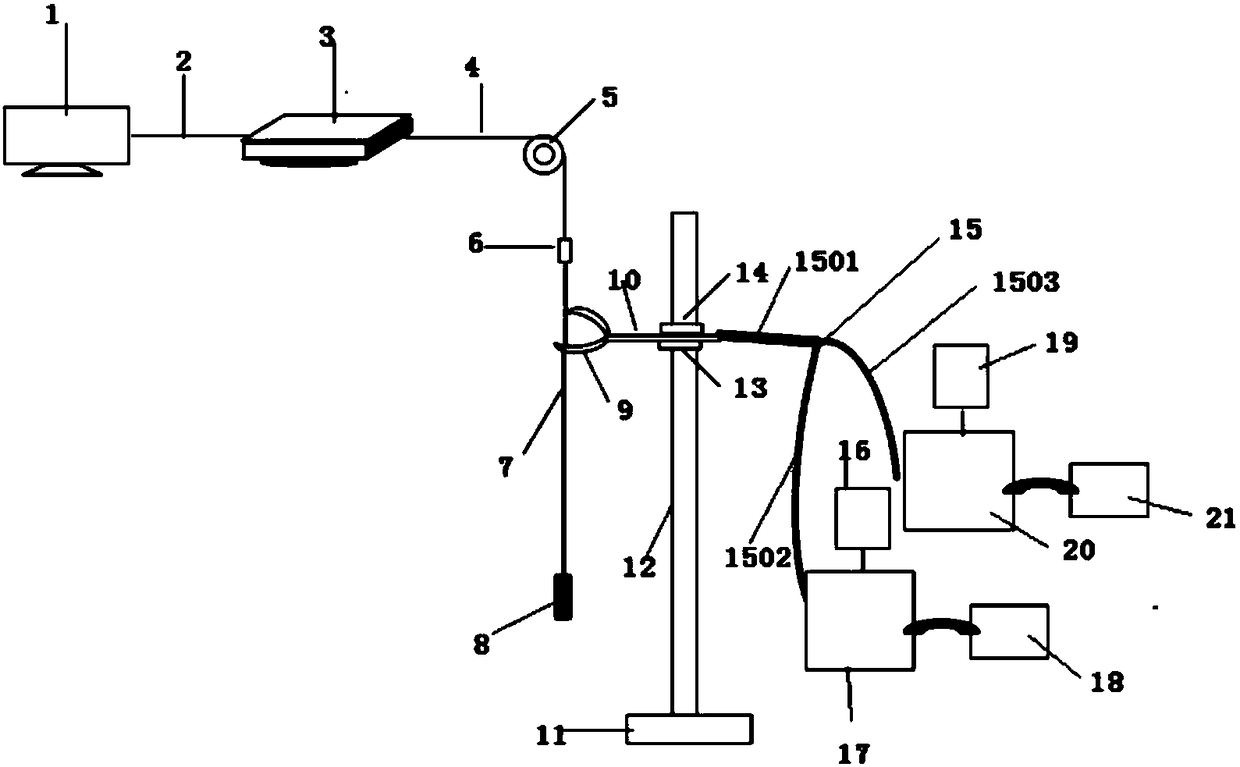

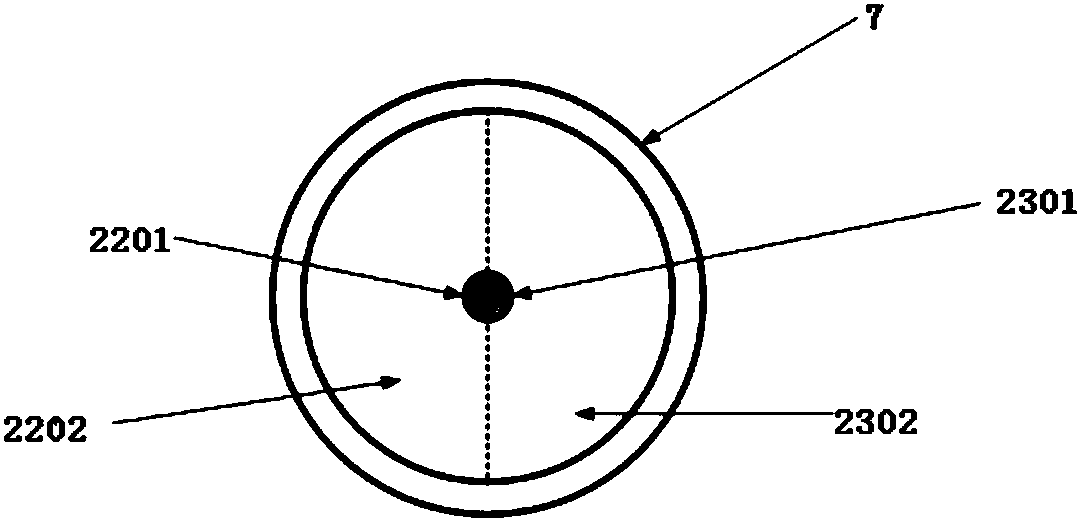

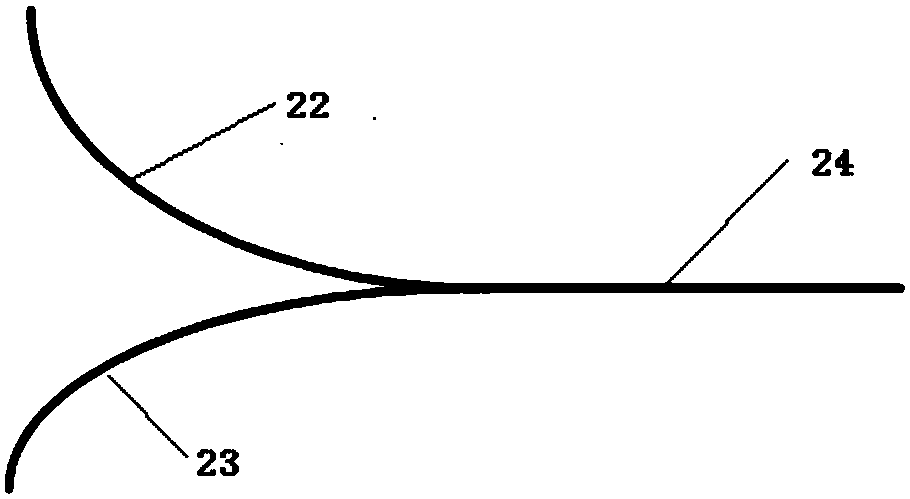

[0041] Such as figure 1 A device and method for making a high-precision and low-loss optical fiber Y splitter shown in the device is characterized in that it includes a computer 1, a data connection line 2, a program-controlled high-precision Mobile platform 3, high-strength connecting wire 4, pulley 5, fixed shelf 6, quartz capillary 7, weight clamp 8, combustion nozzle 9, nozzle pole 10, bracket base 11, bracket rod 12, bracket lower fixture 13, bracket upper Fixture 14, Y-shaped rubber tube 15, mass flow controller I16, mass flow meter I17, oxygen tank 18, mass flow controller II19, mass flow meter II20, hydrogen tank 21; the computer 1 and the program-controlled high-precision mobile platform 3 Connected by data connecting line 2; the optical fiber to be fused is placed in the quartz capillary 7, and the program-controlled high-precision mobile platform 3 passes through the high-strength connecting line 4, pulley 5, fixed shelf 6 and the optical fiber to be fused placed in...

Embodiment 2

[0053] Such as figure 1 A device and method for making a high-precision and low-loss optical fiber Y splitter shown in the device is characterized in that it includes a computer 1, a data connection line 2, a program-controlled high-precision Mobile platform 3, high-strength connecting wire 4, pulley 5, fixed shelf 6, quartz capillary 7, weight clamp 8, combustion nozzle 9, nozzle pole 10, bracket base 11, bracket rod 12, bracket lower fixture 13, bracket upper Fixture 14, Y-shaped rubber tube 15, mass flow controller I16, mass flow meter I17, oxygen tank 18, mass flow controller II19, mass flow meter II20, hydrogen tank 21; the computer 1 and the program-controlled high-precision mobile platform 3 Connected by data connecting line 2; the optical fiber to be fused is placed in the quartz capillary 7, and the program-controlled high-precision mobile platform 3 passes through the high-strength connecting line 4, pulley 5, fixed shelf 6 and the optical fiber to be fused placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com