Plant integrated green building system and construction method thereof

A green building and system technology, applied in buildings, building components, building structures, etc., can solve problems such as unsatisfactory mechanical strength and crack resistance of panels, oxidative damage to steel structures, and numerous construction procedures, so as to achieve pollution-free construction Low energy consumption, good air tightness, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

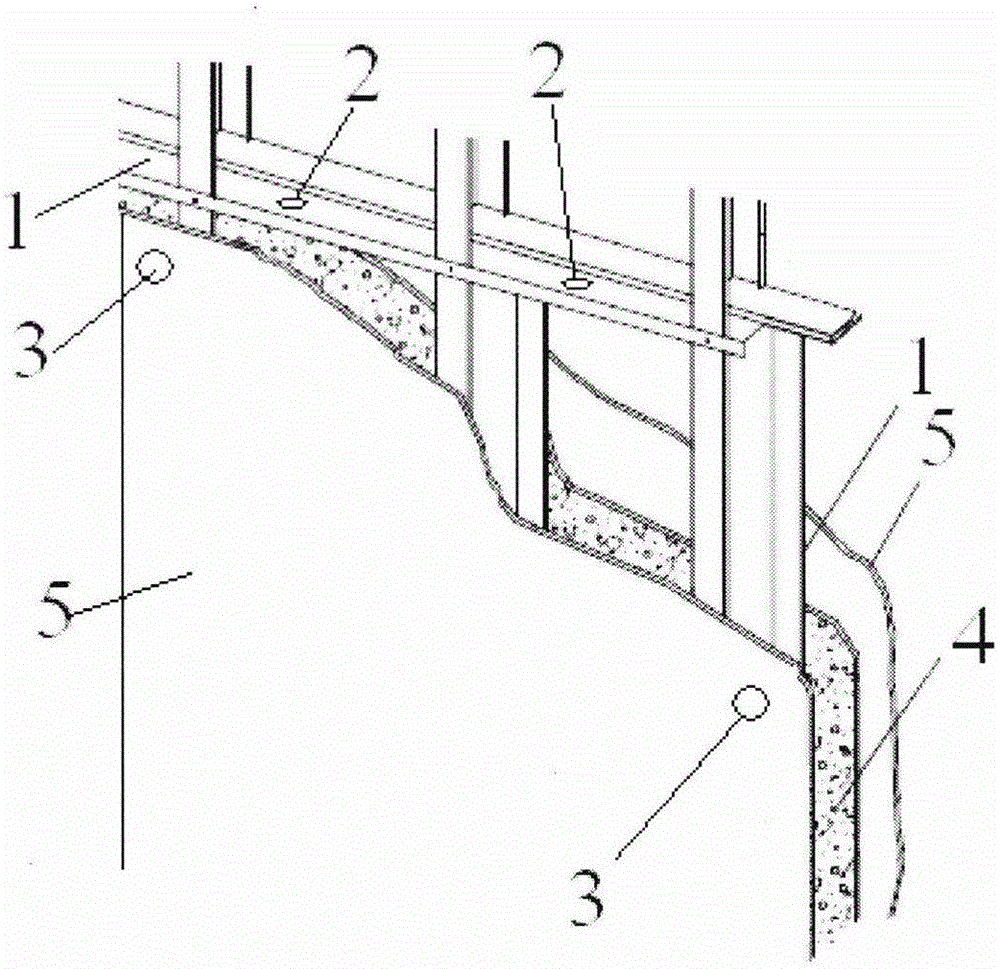

[0015] As shown in the figure: a factory-integrated green building system, including a steel structure frame 1, an inorganic reinforced non-demolition formwork 5 and foamed concrete 4, the bottom and top floors of the steel structure frame 1 are respectively provided with grouting ports 2, and two inorganic reinforced The demolition-free formwork 5 is covered on the upper and lower surfaces of the steel structure frame 1, and the foamed concrete 4 is poured inside the steel structure frame 1 between the two inorganic-reinforced demolition-free formwork 5. The inorganic-reinforced demolition-free formwork 5 is provided with several sets to facilitate exhausting and cooling during pouring. Observe the vent hole 3 for pouring.

[0016] The construction method of the above-mentioned factory integrated green building system, the specific method steps are as follows:

[0017] (1) Assembly: use silicone structural adhesive to bond the inorganic reinforced non-disassembly formwork to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com