Arc-shaped door for linear extraction cutting room

A cutting room and curved door technology, applied in the field of solar photovoltaics, can solve the problems such as laborious opening and closing process for employees, pulleys that cannot slide and get stuck, hidden dangers in operation, etc., to achieve convenient operation for employees, easy push and pull, and protection from damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

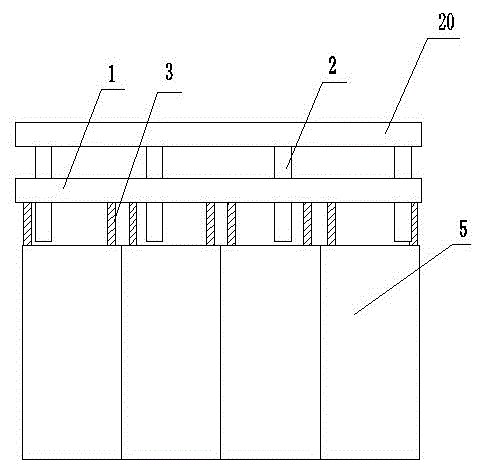

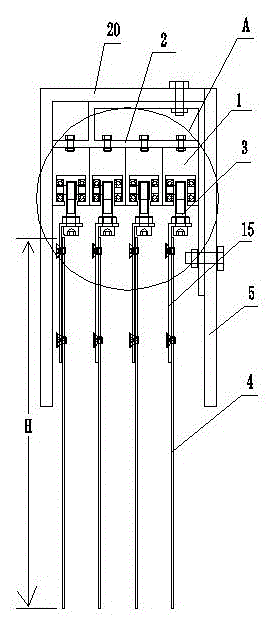

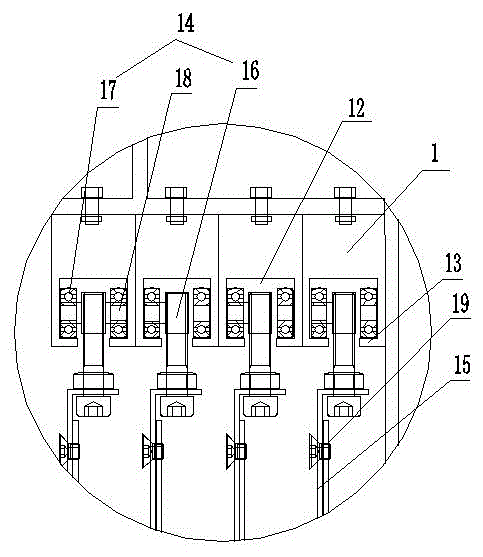

[0022] A kind of arc-shaped door for wire square cutting room, including guide rail 1, guide rail bracket 2, small trolley 3, door panel 4 and baffle plate 5, described guide rail bracket 2 includes guide rail fixing bracket 6, top fixing bracket 7 and baffle Plate fixing bracket 8, the top fixing bracket 7 is welded and fixed on the top of the guide rail fixing bracket 6, the baffle plate fixing bracket 8 is welded and fixed on the sides of the guide rail fixing bracket 6 and the top fixing bracket 7, and the guide rail fixing bracket 6 is provided with Four guide rail fixing through holes 9, a top fixing through hole 10 is provided on the top fixing bracket 7, and a baffle fixing through hole 11 is provided on the baffle fixing bracket 8;

[0023] The guide rail 1 is made of aluminum alloy, and the guide rail 1 has an arc-shaped structure as a whole. The arc length L1 of the guide rail 1 is 3000mm, and the radius r1=1100mm. There is an inwardly folded slideway plate 13 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com