Silent air filtering device with efficient cyclic utilization function

An air filter device and high-efficiency technology, which is applied in the directions of jet propulsion device, gas turbine device, air inlet of turbine/propulsion device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

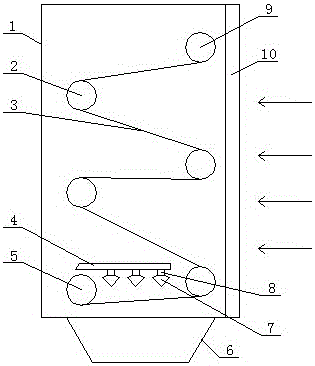

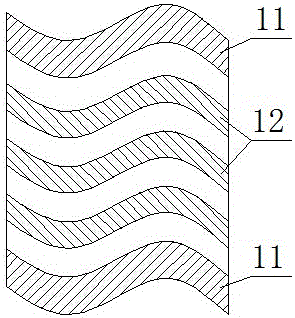

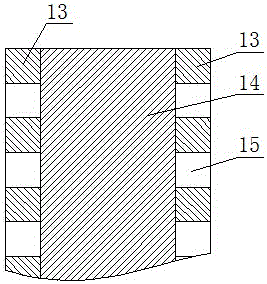

[0049] The high-efficiency recycling noise reduction air filter device of this embodiment includes a top driving drum installed in the filter room, a bottom driving drum and a driven drum installed between the top driving drum and the bottom driving drum, and the driven drum The left and right are alternately installed in the filter room; the top driving drum, driven drum and bottom driving drum are coated with filter layers, and the side of the filter room is provided with an air inlet, and the air inlet is facing the coating The filter layer on the top drive drum, the driven drum and the bottom drive drum; the blowing system is arranged above the filter layer between the driven drum and the bottom drive drum at the bottom of the filter house, and the air inlet is equipped with A noise reduction module is provided, and the noise reduction module includes two first noise reduction modules and at least one second noise reduction module, and the second noise reduction module is a...

Embodiment 2

[0051] The high-efficiency recycling noise reduction air filter device of this embodiment includes a top driving drum installed in the filter room, a bottom driving drum and a driven drum installed between the top driving drum and the bottom driving drum, and the driven drum The left and right are alternately installed in the filter room; the top driving drum, driven drum and bottom driving drum are coated with filter layers, and the side of the filter room is provided with an air inlet, and the air inlet is facing the coating The filter layer on the top drive drum, the driven drum and the bottom drive drum; the blowing system is arranged above the filter layer between the driven drum and the bottom drive drum at the bottom of the filter house, and the air inlet is equipped with A noise reduction module is provided, and the noise reduction module includes two first noise reduction modules and at least one second noise reduction module, and the second noise reduction module is a...

Embodiment 3

[0053] The high-efficiency recycling noise reduction air filter device of this embodiment includes a top driving drum installed in the filter room, a bottom driving drum and a driven drum installed between the top driving drum and the bottom driving drum, and the driven drum The left and right are alternately installed in the filter room; the top driving drum, driven drum and bottom driving drum are coated with filter layers, and the side of the filter room is provided with an air inlet, and the air inlet is facing the coating The filter layer on the top drive drum, the driven drum and the bottom drive drum; the blowing system is arranged above the filter layer between the driven drum and the bottom drive drum at the bottom of the filter house, and the air inlet is equipped with A noise reduction module is provided, and the noise reduction module includes two first noise reduction modules and at least one second noise reduction module, and the second noise reduction module is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com