Synchronous belt positioning system

A positioning system and synchronous belt technology, applied in belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of difficult processing and manufacturing, difficult maintenance and replacement, and difficult replacement and maintenance, and achieve low maintenance and replacement costs and high precision. The effect of reducing requirements and saving time and effort in assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the present invention will be further described in detail through the drawings and embodiments. Through these descriptions, the characteristics and advantages of the present invention will become clearer.

[0042] The dedicated word "exemplary" here means "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" need not be construed as being superior or better than other embodiments. Although various aspects of the embodiments are shown in the drawings, unless otherwise noted, the drawings are not necessarily drawn to scale.

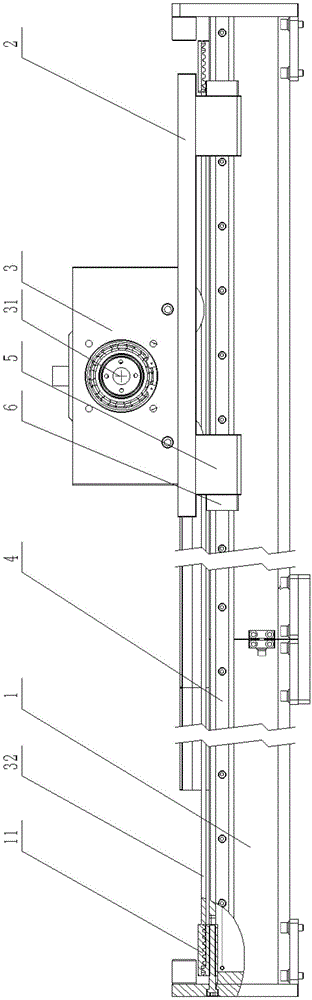

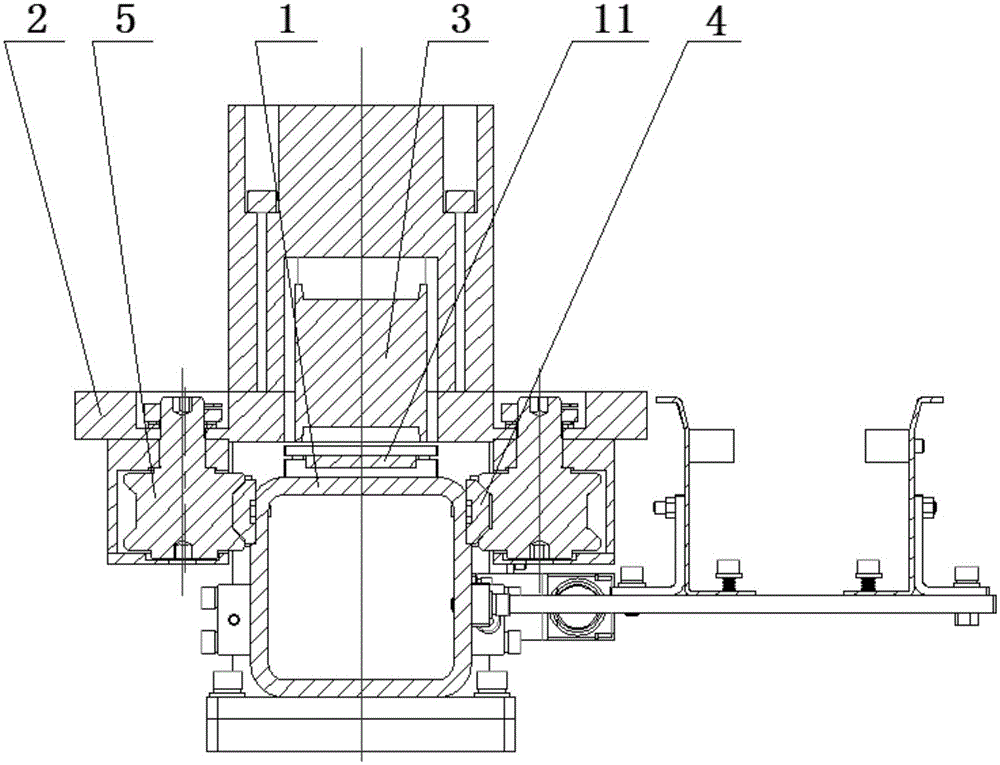

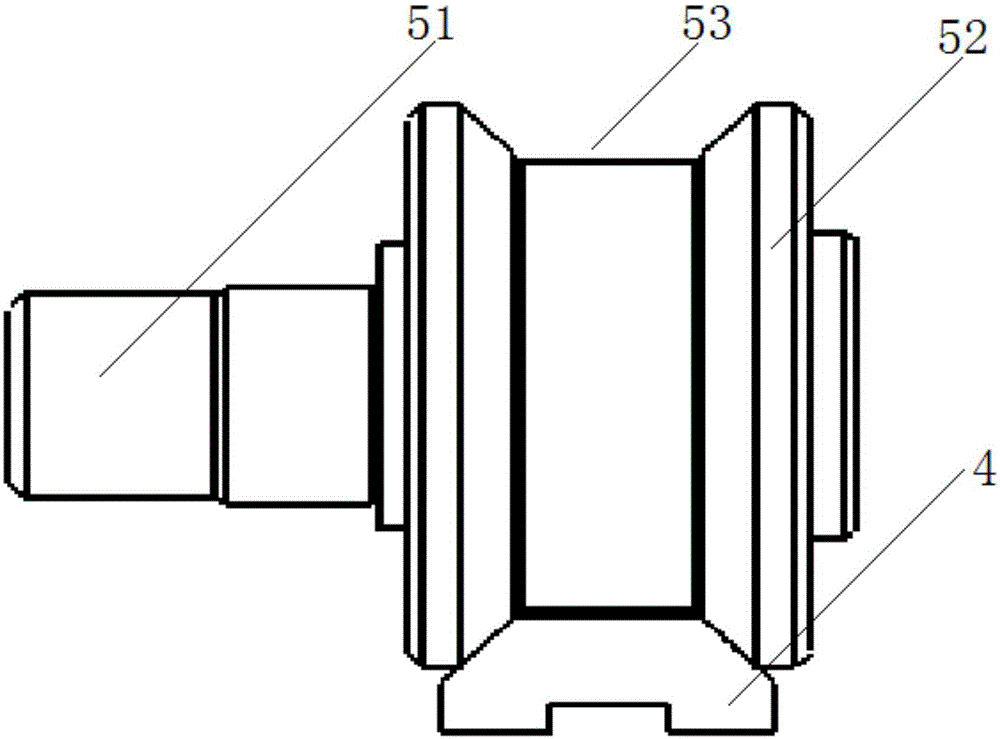

[0043] According to the timing belt positioning system provided by the present invention, such as figure 1 , figure 2 As shown in the figure, the system includes a main beam 1 and a sliding plate 2 arranged above the main beam 1. The sliding plate can slide reciprocatingly along the longitudinal direction of the main beam, thereby driving other components placed on the sliding plate to move tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com