Anhydrous test method for ultrasonic flowmeter

An ultrasonic and flowmeter technology, which is applied in the field of ultrasonic flowmeter anhydrous detection, can solve the problems of inability to quantify and poor objectivity of ear judgment, and achieve the effects of ensuring measurement accuracy, reducing operation and maintenance costs, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

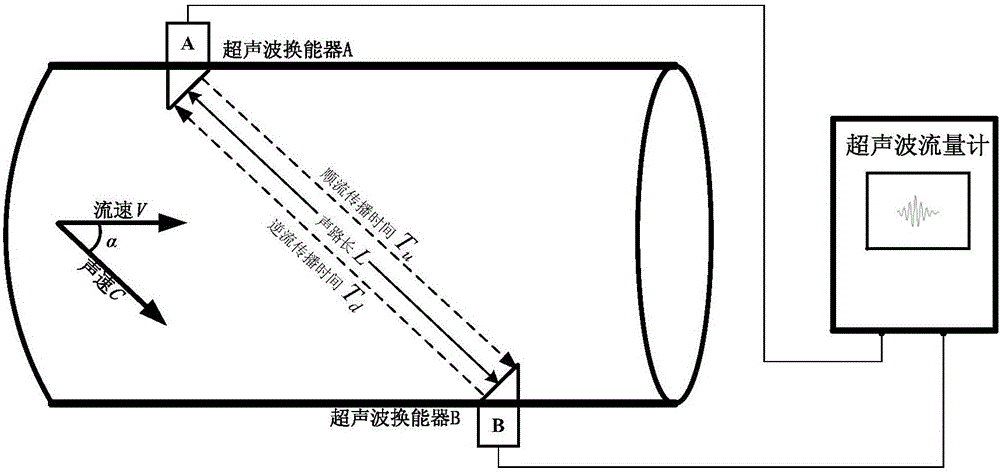

[0046] Ultrasonic flowmeter detection is closely related to its working principle. Since the development of ultrasonic flowmeter, among many measurement methods, transit-time ultrasonic flowmeter has the advantages of simple measurement method and high measurement accuracy, and has always attracted attention. The principle of the time-difference ultrasonic flowmeter is to calculate the flow velocity based on the difference between the propagation time of the ultrasonic signal and the upstream propagation time, so as to calculate the flow rate.

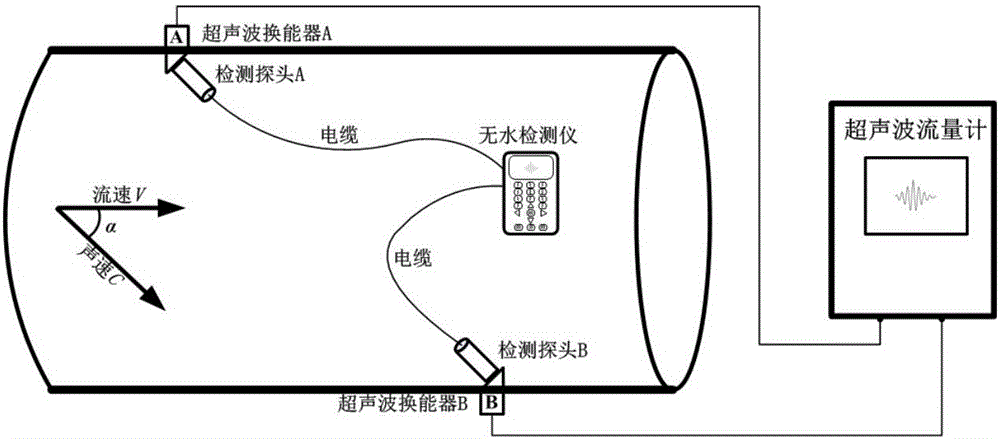

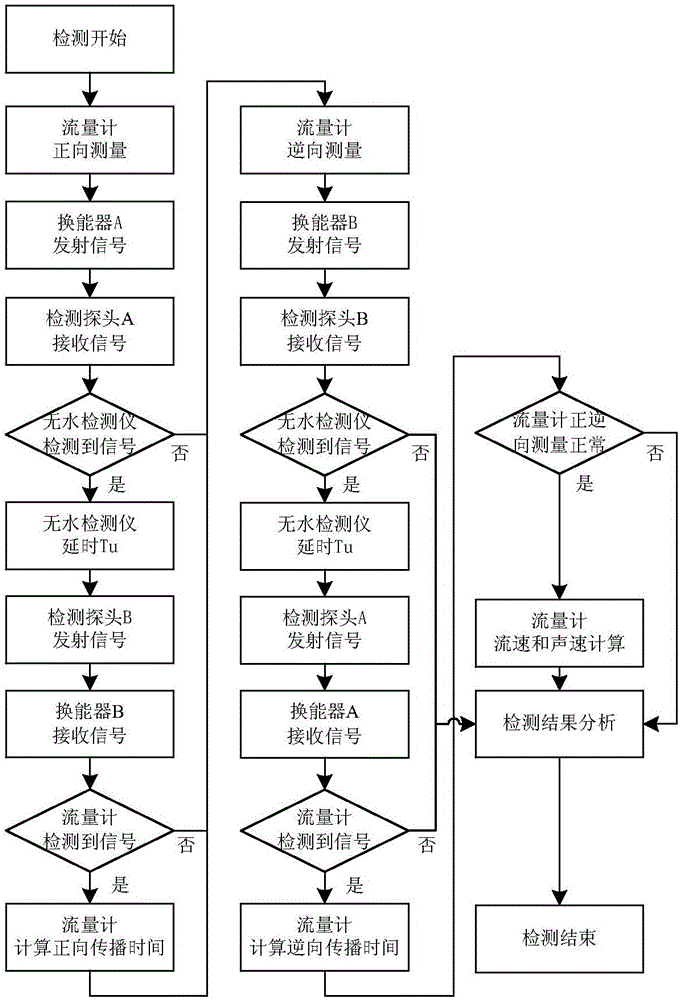

[0047] The working principle of the transit time ultrasonic flowmeter is as follows: figure 1 As shown, this is a flow measurement schematic diagram of a pressurized pipeline. Ultrasonic transducers A and B are a pair of transducers in the same sound path, when one of them is used as a transmitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com