A method for measuring the bonding force between multi-walled nanotubes

A technology of multi-walled nanotubes and cohesive force, applied in the field of measurement, can solve the problems of complex operation process, harsh conditions, low efficiency, etc., and achieve simple and convenient operation process, improved accuracy and precision, high accuracy and precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

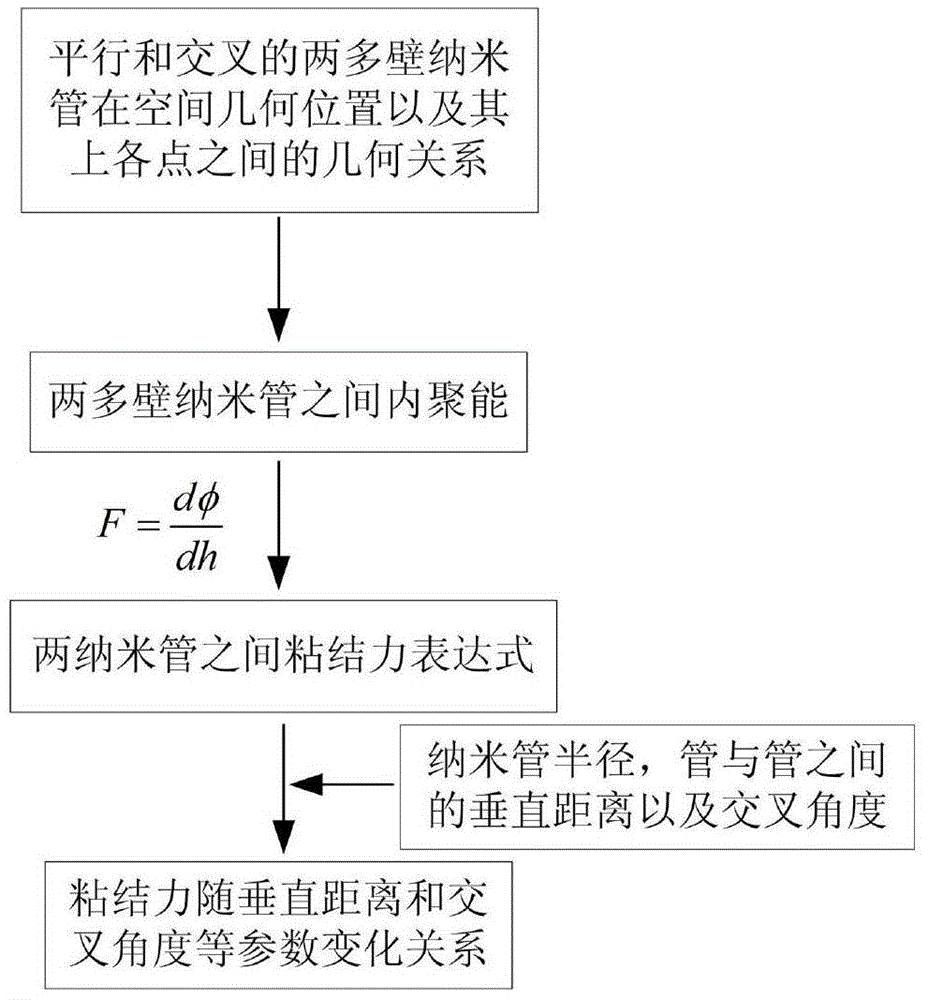

[0034] Such as figure 1 Shown, the present invention comprises three steps:

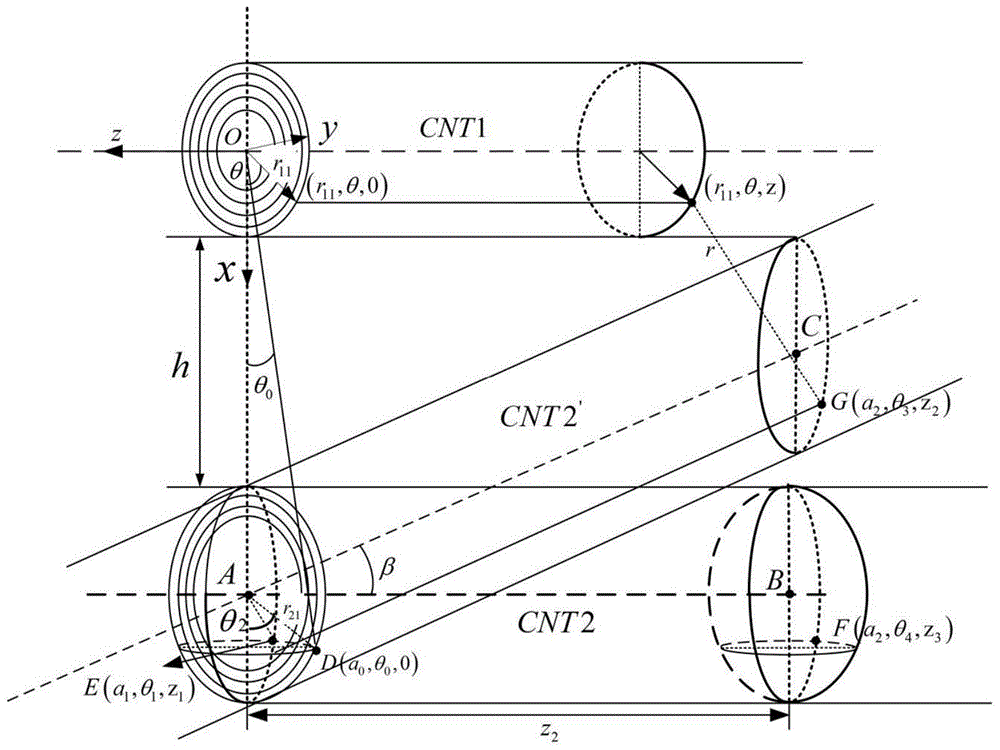

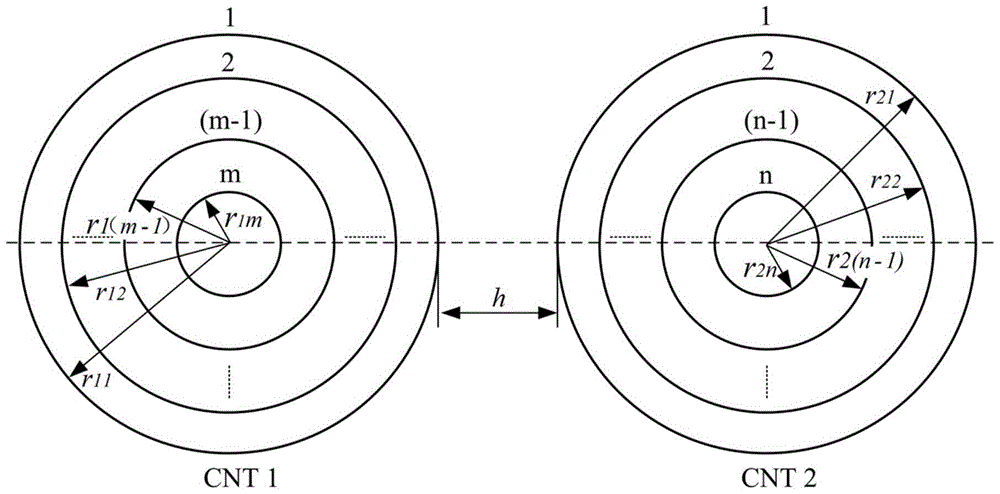

[0035] Step 1: The geometry and spatial distribution of parallel and crossed two multi-walled nanotubes as figure 2 As shown in the figure, the axes of the multi-walled nanotubes CNT1 and CNT2 are parallel to each other, and the number of layers is m and n respectively. The radius of each layer on the two nanotubes is r 1i (1≤i≤m) and r 2j (1≤j≤n), such as image 3 shown. to rotate figure 2 At one end of the medium nanotube CNT2, when a certain point D on it moves to point E, the corresponding point B rotates to point C. The rotated nanotube is labeled CNT2', and its intersection angle with the CNT1 or CNT2 axis is β. In the cylindrical coordinate system (r, θ, z), the z axis is along the central axis of the nanotube CNT1. A vertical line perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com