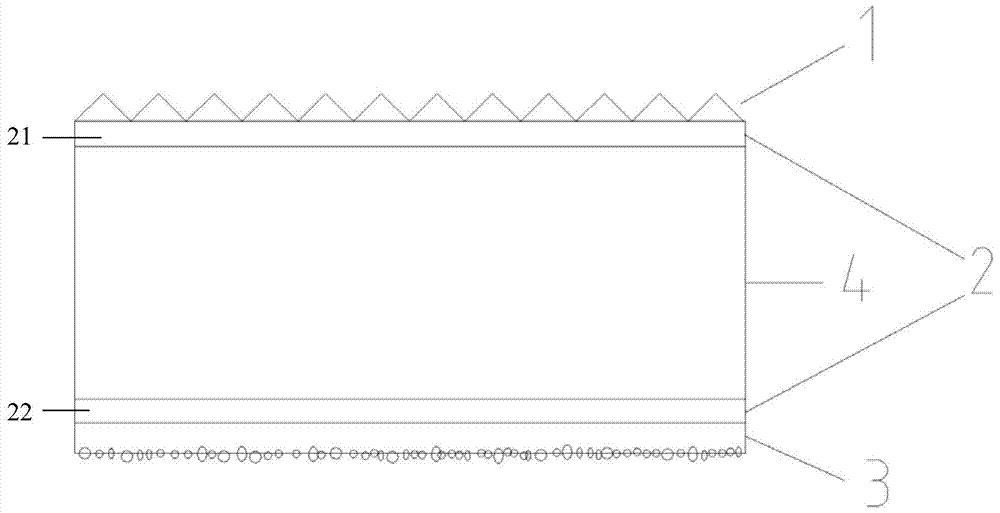

A kind of composite brightening film and preparation method thereof

A technology of brightness-enhancing film and polyurethane layer, which is applied in the direction of prisms, etc., can solve the problems of overall thickness, easy to produce light shadows, and insufficient brightness of small-sized displays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

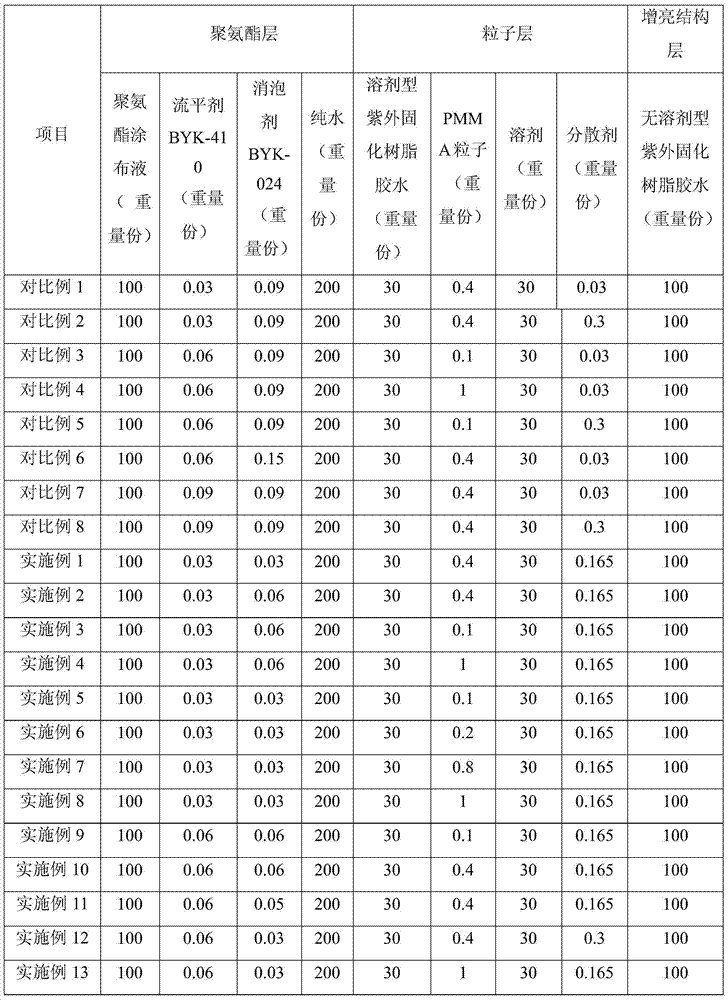

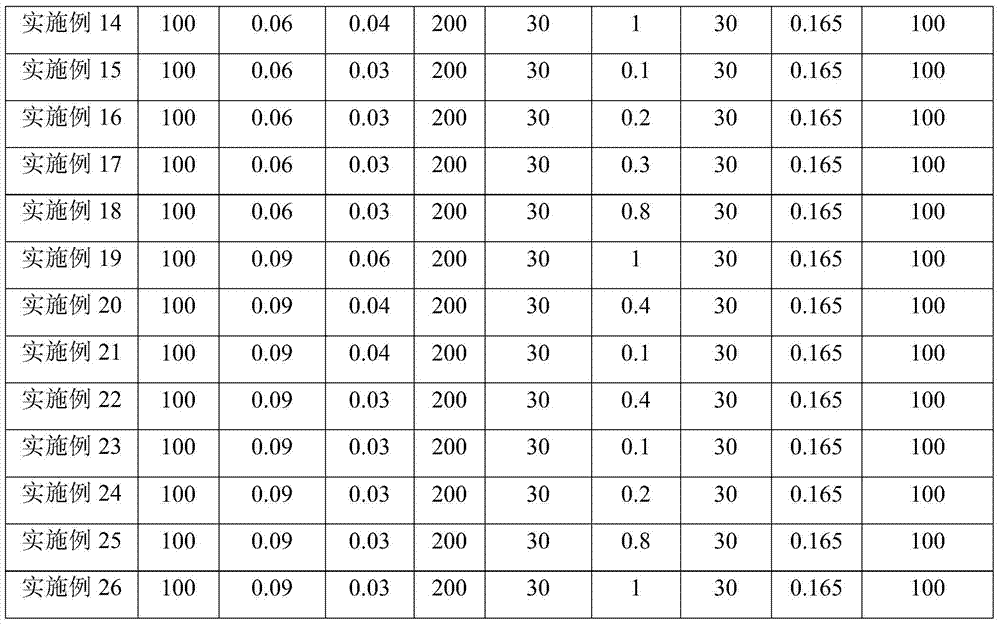

Embodiment 1

[0065] In the composite brightening film provided by the present invention, 100 parts of polyurethane coating solution, 0.03 parts of polydimethylsiloxane leveling agent BYK-410, 0.03 parts of defoamer BYK-024, and 200 parts of pure water 30 parts of solvent-based UV curing resin glue, 30 parts of solvent, 0.4 parts of PMMA particles, 0.165 parts of dispersant, Mix evenly with a stirrer and apply it on the lower surface of the PET film with the polyurethane layer, dry it in an oven at 80°C for 1min, and then use a high-pressure mercury lamp at 400mj / cm 2 The total energy of the film is irradiated to make it UV hardened to obtain a film with a particle layer; then the solvent-free UV-curable glue is coated on the upper surface of the PET with a polyurethane coating, and it is extruded by a special engraved roller , and at 450mj / cm 2 Irradiated by a high-pressure mercury lamp to make it solidify and form, and finally obtain a composite brightness-enhancing film.

[0066] The b...

Embodiment 2

[0069] In the composite brightening film provided by the present invention, 100 parts of polyurethane coating solution, 0.03 parts of polydimethylsiloxane leveling agent BYK-410, 0.06 parts of defoamer BYK-024, and 200 parts of pure water 30 parts of solvent-based UV curing resin glue, 30 parts of solvent, 0.4 parts of PMMA particles, 0.165 parts of dispersant, Mix evenly with a stirrer and apply it on the lower surface of the PET film with the polyurethane layer, dry it in an oven at 80°C for 1min, and then use a high-pressure mercury lamp at 400mj / cm 2 The total energy of the film is irradiated to make it UV hardened to obtain a film with a particle layer; then the solvent-free UV-curable glue is coated on the upper surface of the PET with a polyurethane coating, and it is extruded by a special engraved roller , and at 450mj / cm 2 Irradiated by a high-pressure mercury lamp to make it solidify and form, and finally obtain a composite brightness-enhancing film.

[0070] The b...

Embodiment 3

[0073] In the composite brightening film provided by the present invention, 100 parts of polyurethane coating solution, 0.03 parts of polydimethylsiloxane leveling agent BYK-410, 0.06 parts of defoamer BYK-024, and 200 parts of pure water 30 parts of solvent-based UV curing resin glue, 30 parts of solvent, 0.1 part of PMMA particles, 0.165 parts of dispersant, Mix evenly with a stirrer and apply it on the lower surface of the PET film with the polyurethane layer, dry it in an oven at 80°C for 1min, and then use a high-pressure mercury lamp at 400mj / cm 2 The total energy of the film is irradiated to make it UV hardened to obtain a film with a particle layer; then the solvent-free UV-curable glue is coated on the upper surface of the PET with a polyurethane coating, and it is extruded by a special engraved roller , and at 450mj / cm 2 Irradiated by a high-pressure mercury lamp to make it solidify and form, and finally obtain a composite brightness-enhancing film.

[0074] The br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com