Transparent display device and manufacturing method thereof

A technology of transparent display and light-transmitting area, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

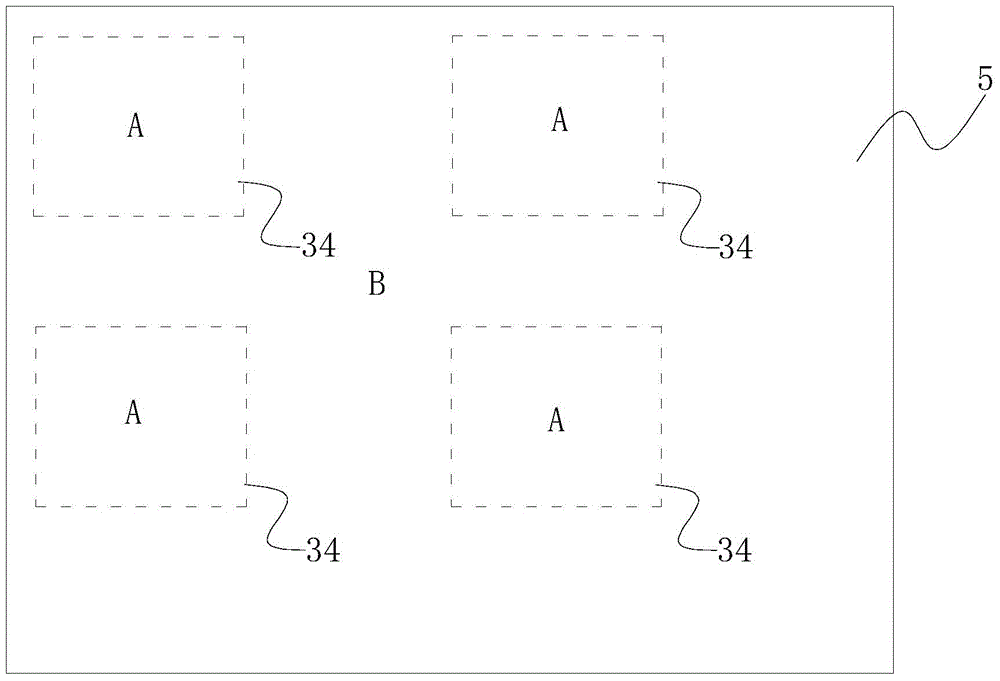

[0028] The transparent display includes a pixel area and a light-transmitting area. Wherein, a plurality of the pixel areas are arranged on the transparent display, and the pixel areas are used to emit light of three colors of RGB. The light-transmitting area is located between the pixel areas, that is, the area outside the pixel areas on the transparent display. The light-transmitting region is permeable to light, which directly affects the light-transmitting property and display effect of the transparent display.

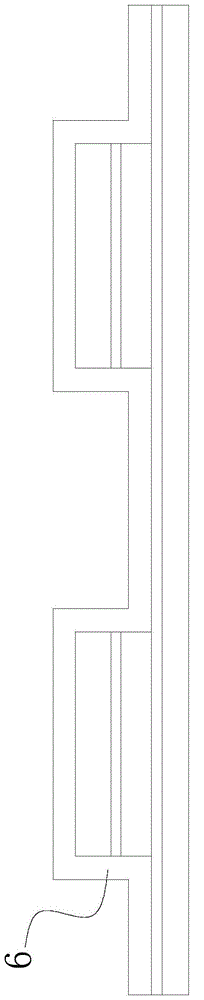

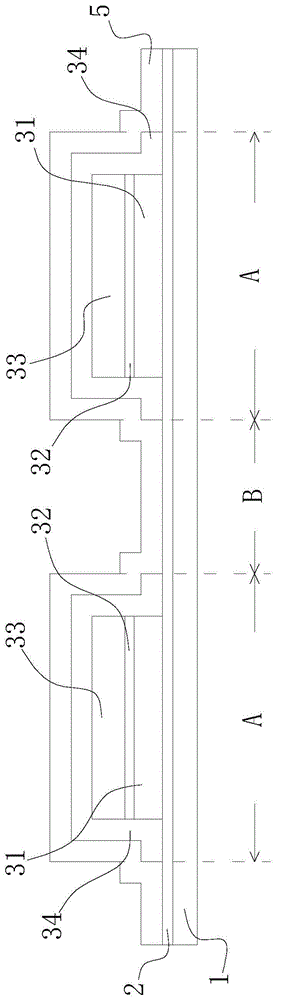

[0029] Please also see figure 2 and image 3 , which respectively show a longitudinal cross-sectional structural schematic view and a front view of the transparent display according to the first embodiment of the present invention. Such as figure 2 and image 3 As shown, in a preferred embodiment of the present invention, the transparent display includes a substrate 1, a buffer layer 2, and a plurality of organic electroluminescent devices. The substrate 1...

no. 2 example

[0042] See Figure 8 , which shows a schematic view of the vertical cross-sectional structure of the transparent display according to the second embodiment of the present invention. Such as Figure 8 shown, with the above figure 2 and image 3 The difference from the first embodiment shown is that the transparent display in this embodiment has a bottom emission structure, and the structure of the organic electroluminescent device is different from that in the first embodiment above. Specifically, the organic electroluminescent device of the transparent display includes: a thin film transistor 31', an anode 32', a light emitting layer 33' and a first cathode 34'.

[0043] The thin film transistor 31' is disposed on the pixel area of the substrate 1. The thin film transistor 31' is preferably a low temperature polysilicon thin film transistor. The anode 32' is disposed on the substrate 1 and is located on the side of the thin film transistor 31'. The light-emitting laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com