Thin inductor embedded structure

A technology of inductive components and electronic components, which is applied in the directions of printed circuits connected with non-printed electrical components, transformer/reactor installation/support/suspension, etc. Problems such as inability to improve, to achieve the effects of easy processing and manufacturing, simplified structure, and improved production yield and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The embodiments of the present invention will be described in more detail below with reference to the drawings and reference numerals, so that those skilled in the art can implement them after studying this specification.

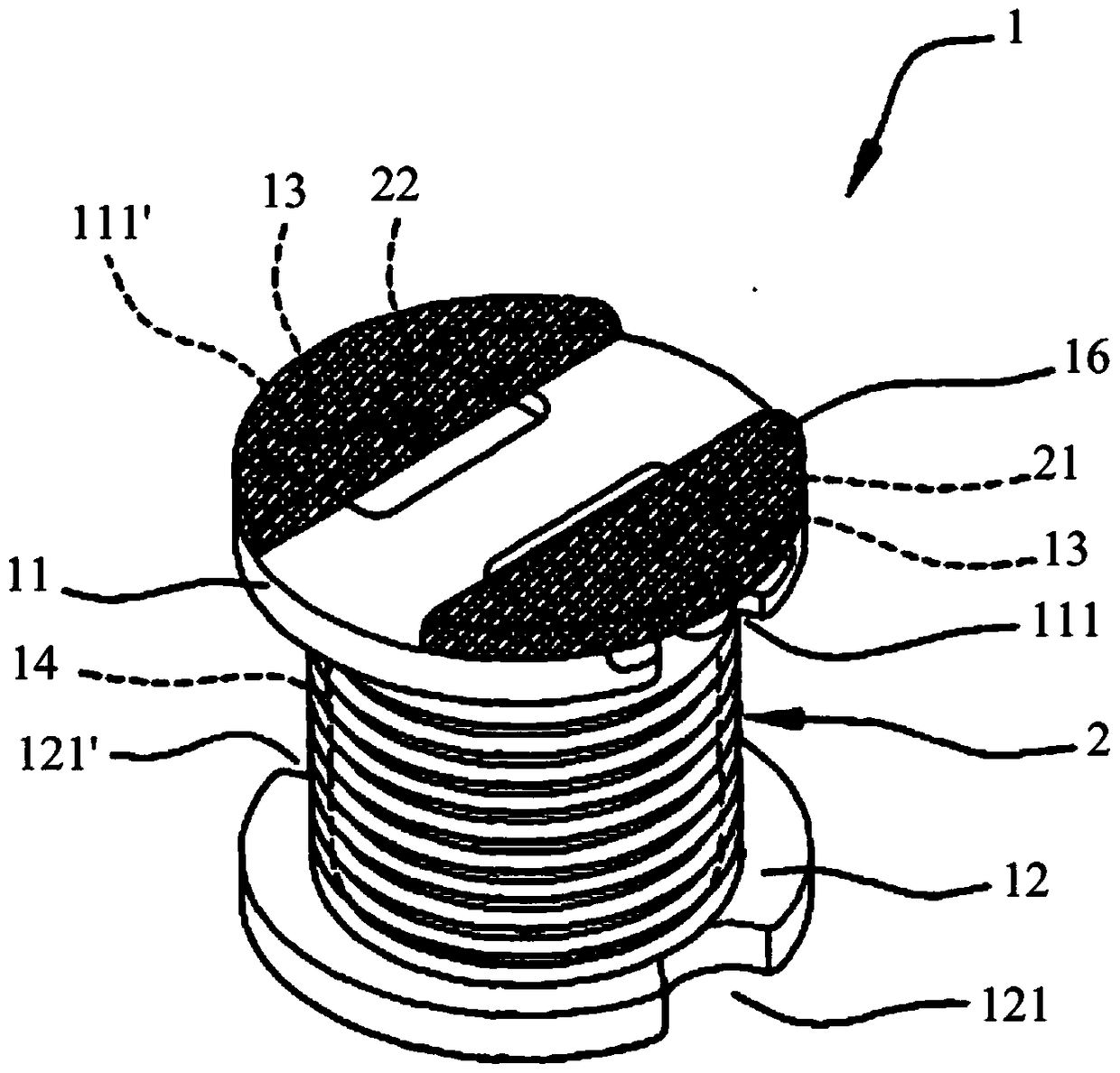

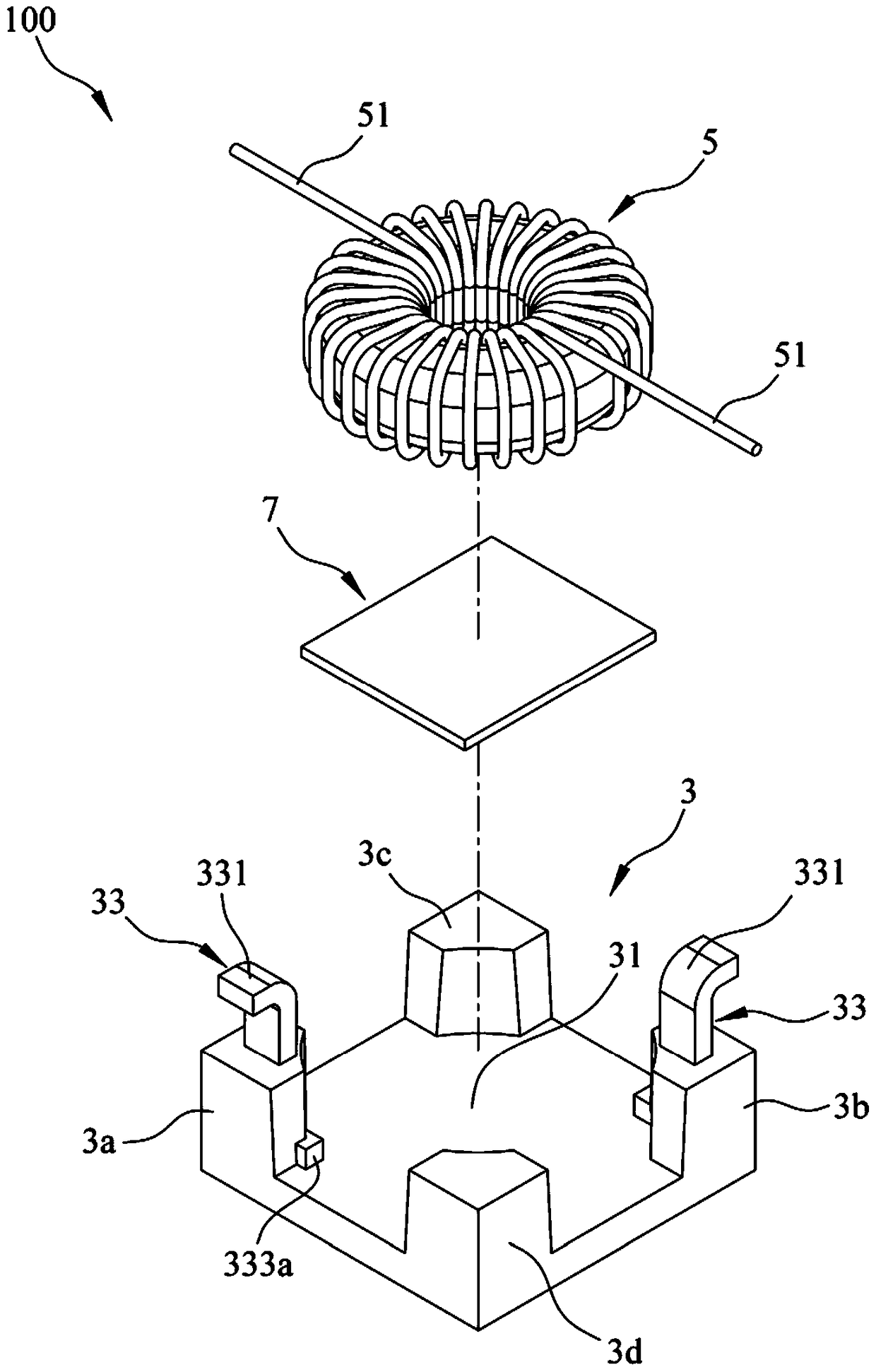

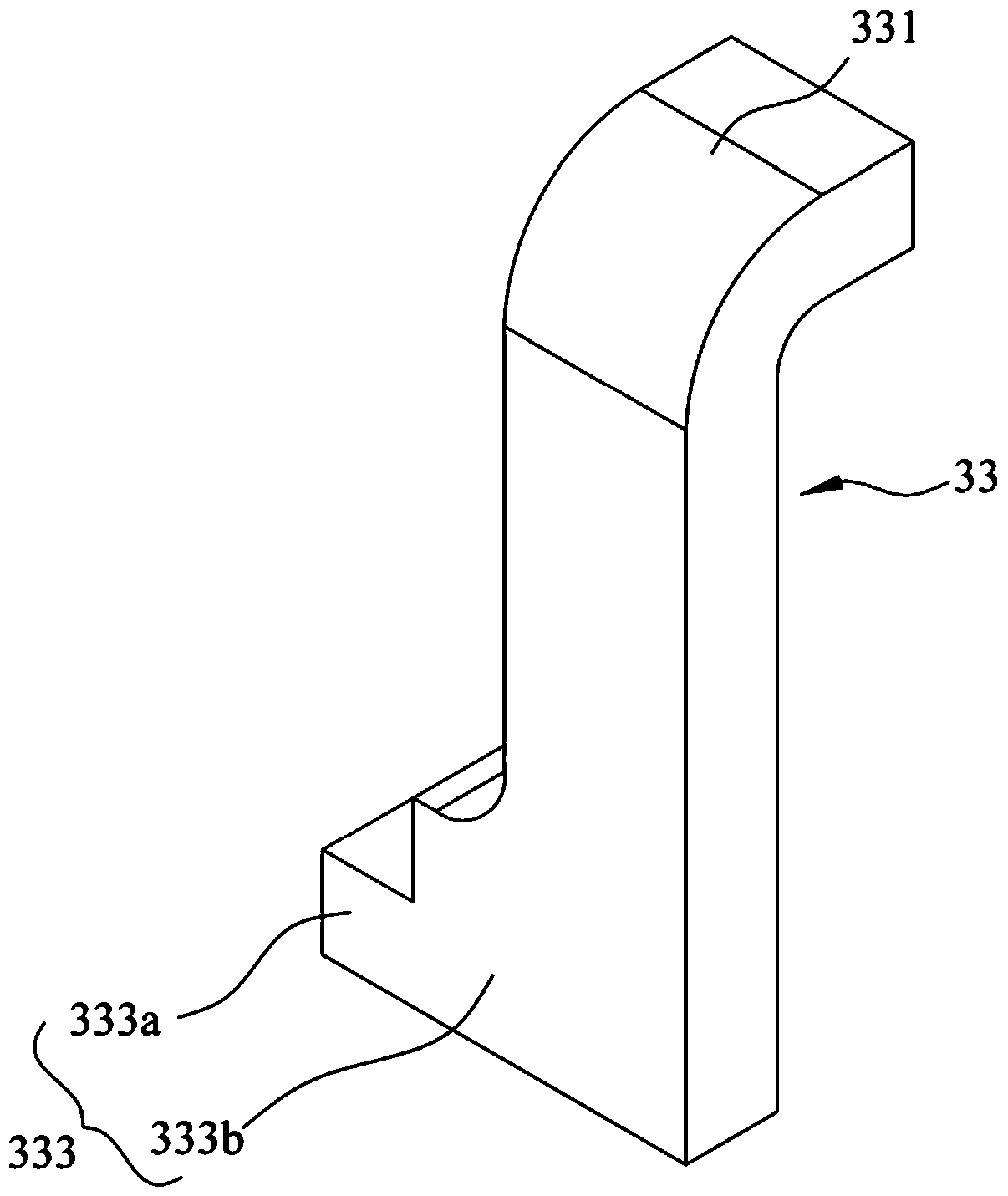

[0055] refer to figure 2 , the three-dimensional exploded view of the first preferred embodiment of the thinned inductance element embedded structure of the present invention, refer to Figure 5 , the side cross-sectional view of the first preferred embodiment of the thinned inductance element embedded structure of the present invention. like figure 2 As shown, the thinned inductance element embedding structure 100 of the present invention at least includes a base 3, a coil 5 and an electronic component 7, wherein a cavity 31 is formed on one side of the base 3, and the cavity 31 and There is an accommodating space, and the base 3 is preset with two terminals 33; wherein, the base 3 is made of insulating material, and the wall surrounding the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com