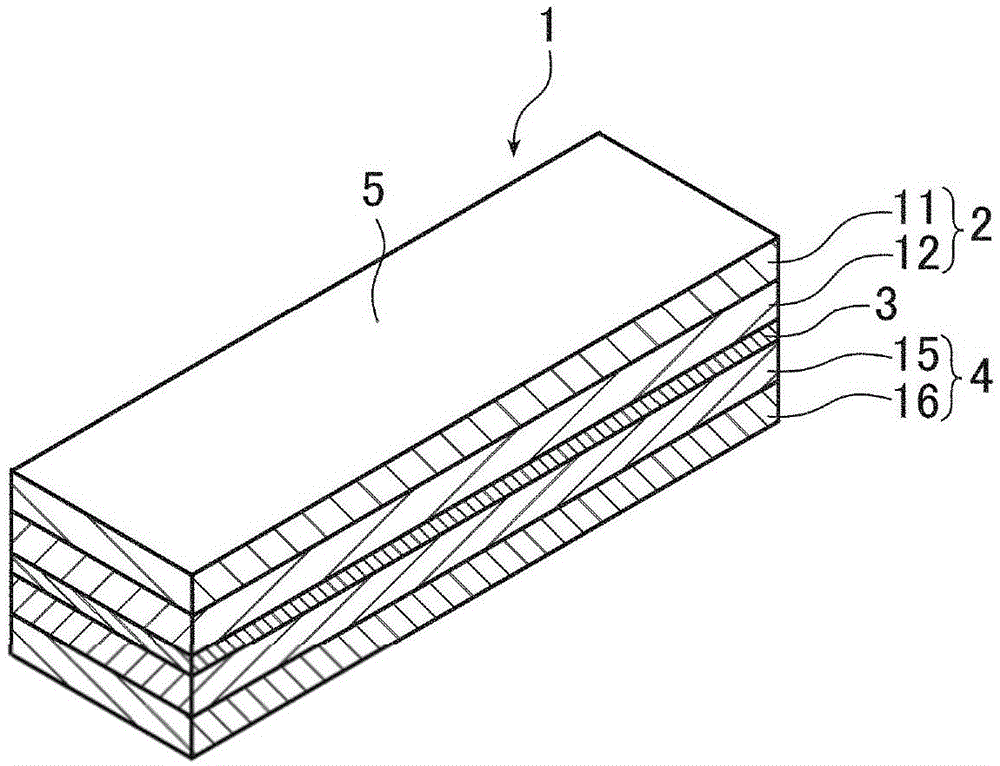

Rubber composition for conveyor belt, and conveyor belt

A technology of rubber composition and conveyor belt, applied in the direction of conveyor, transportation and packaging, can solve the problems of high tanδ, power saving can not meet recent people's requirements, etc., and achieve the effect of excellent power saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

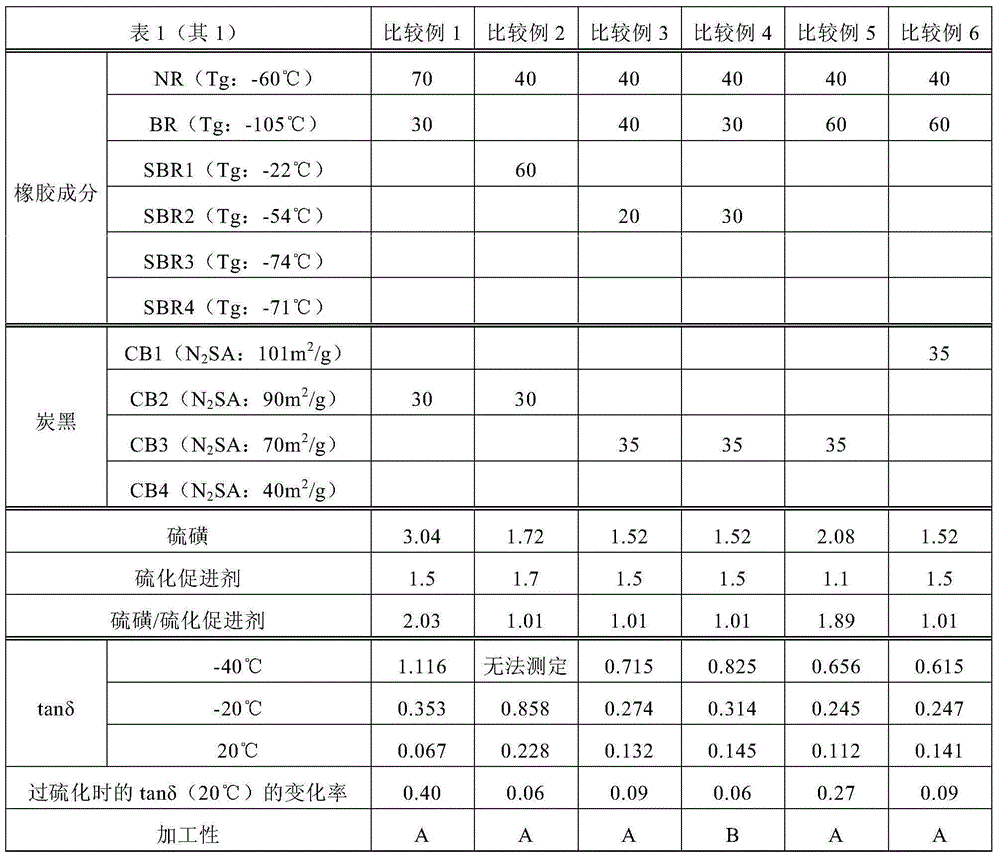

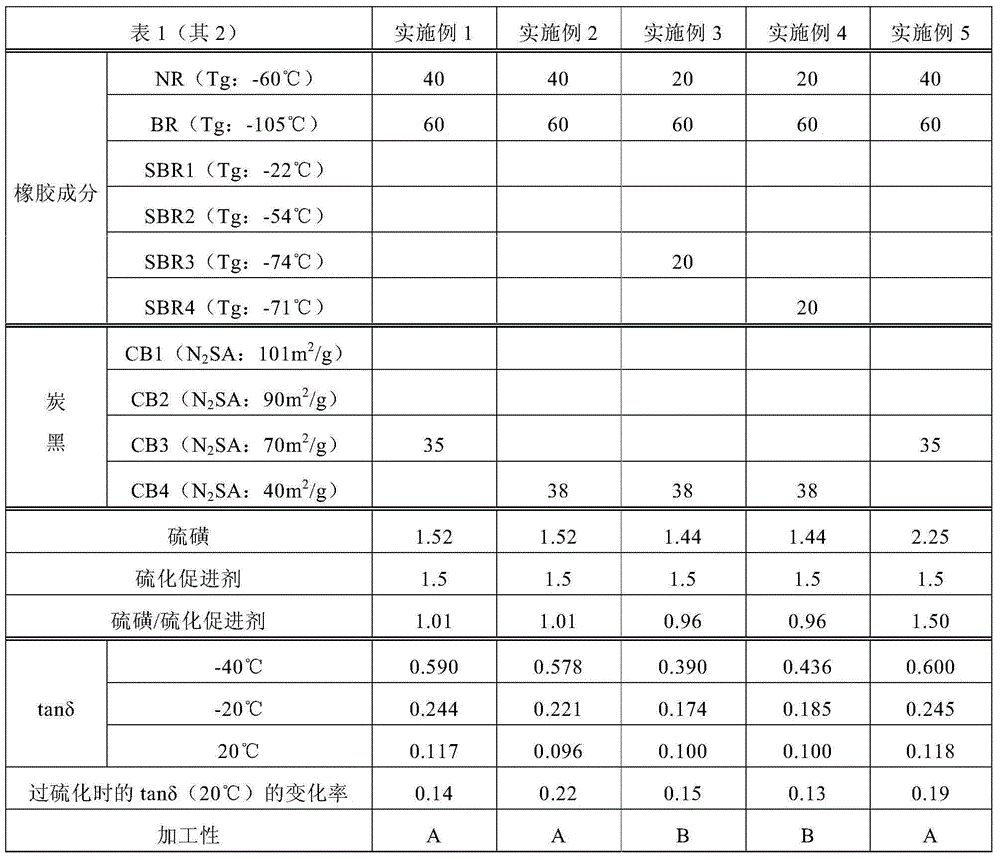

Embodiment 1~5、 comparative example 1~6

[0119] The components shown in Table 1 below were mixed in proportions (parts by mass) shown in Table 1 below to prepare a rubber composition for conveyor belts.

[0120]

[0121] The obtained rubber composition was vulcanized at 148° C. for 30 minutes to prepare a vulcanized rubber composition. Then, the prepared vulcanized rubber composition was cut into short strips (20 mm in length×5 mm in width×2 mm in thickness) to obtain test pieces.

[0122] The tan δ of the obtained test piece was measured using a viscoelasticity spectrometer (manufactured by Toyo Seiki Seisakusho Co., Ltd.) (measurement temperature: -40°C, -20°C, 20°C). In addition, when measuring tan δ, the test piece was stretched by 10%, and a vibration of an amplitude of ±2% was applied at a frequency of vibration of 20 Hz. The results are shown in Table 1. In view of the excellent power-saving properties at low temperatures, tan δ at -40° C. is preferably 0.600 or less in actual use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com