Excitation control method for electro-excitation long-afterglow light-emitting system

A long afterglow luminescence and electro-excitation technology, which is applied in the direction of light control, electroluminescence light source, non-electric variable control, etc., can solve the problems of low excitation efficiency, too simple function of the drive control circuit, and low minimum brightness value of the luminescence system, etc. problem, to achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

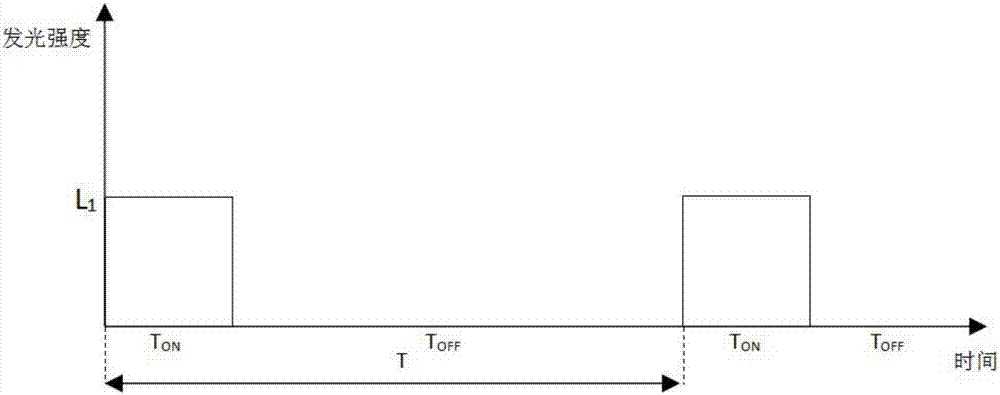

[0081] An electroluminescence long afterglow luminescence system adopts a traditional excitation method, and an electroluminescence source (3) emits light intermittently with a period of 10s and a duty ratio of 20%. The current passing through the electroluminescence source (3) in the Ton phase is a continuous constant current with an amplitude of 10 mA. Under this excitation control method, the luminous intensities of the electroluminescent source (3) and the long-lasting luminescent material (4) of the electro-excitation long-lasting luminescent system are as follows: Figure 8 , 10 As shown, the superimposed schematic diagram of the luminous intensity of the electro-excited long afterglow luminescent system is shown in Figure 12 shown.

[0082] Because the current amplitude of the electroluminescent source (3) is too small, the excitation efficiency of the long-lasting luminescent material (4) is too low. The excitation control method of the present invention is now used...

Embodiment 2

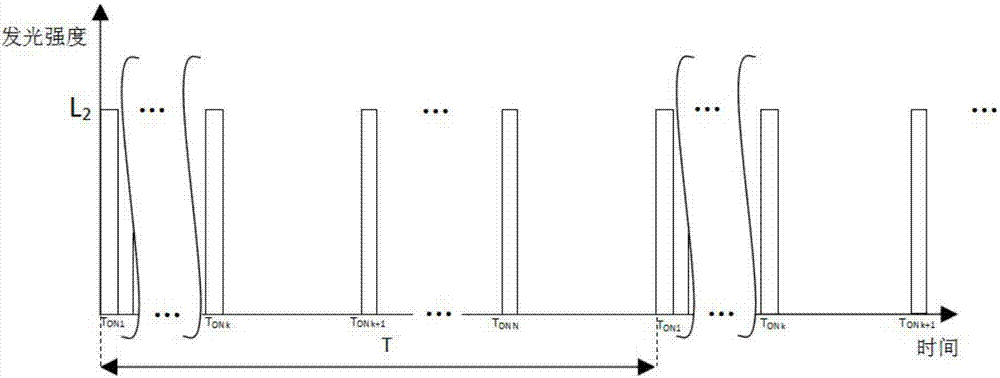

[0084] An electroluminescence long afterglow luminescence system adopts an improper excitation control method of the present invention, and the electroluminescence source (3) emits light intermittently with a period of 10s and a duty ratio of 6%. The current passing through the high-frequency excitation period of one cycle is a rectangular pulse current with an amplitude of 75mA, a frequency of 100HZ, and a pulse width of 2ms. Under this excitation control method, the luminous intensities of the electroluminescent source (3) and the long-lasting luminescent material (4) of the electro-excitation long-lasting luminescent system are as follows: Figure 15 , 17 As shown, the superimposed schematic diagram of the luminous intensity of the electro-excited long afterglow luminescent system is shown in Figure 19 As shown, the luminous intensity change of the electro-excited long-lasting light-emitting system observed by the human eye, that is, the average luminous intensity of the ...

Embodiment 3

[0087]An electro-excited long afterglow luminescent system, comprising a power supply (1), a drive control circuit (2), an LED light source (3), and a long afterglow luminescent material (4); the power supply (1) is a storage battery; the The drive control circuit (2) includes a drive circuit and a PWM control circuit; the PWM control circuit is a single-chip microcomputer with a PWM control function, connected to the loop through a MOS tube, and controlled by outputting a PWM signal to control the on-off of the MOS tube Excitation of the LED light emitting source (3); the LED light emitting source (3) is arranged on the bottom surface or below the long afterglow luminescent material (4), and plays the role of actively emitting light and exciting the long afterglow luminescent material (4); the LED The light emitting source (3) and the power supply (1) are respectively connected with the drive circuit through lines to form a closed loop.

[0088] After the circuit is turned on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com