LED circuit board with COB packaging substrate

A technology of LED circuit boards and packaging substrates, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as interference with luminous efficiency, reduced luminous effect, and insufficient heat dissipation, and achieve increased refractive index, improved luminous effect, and improved luminous effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

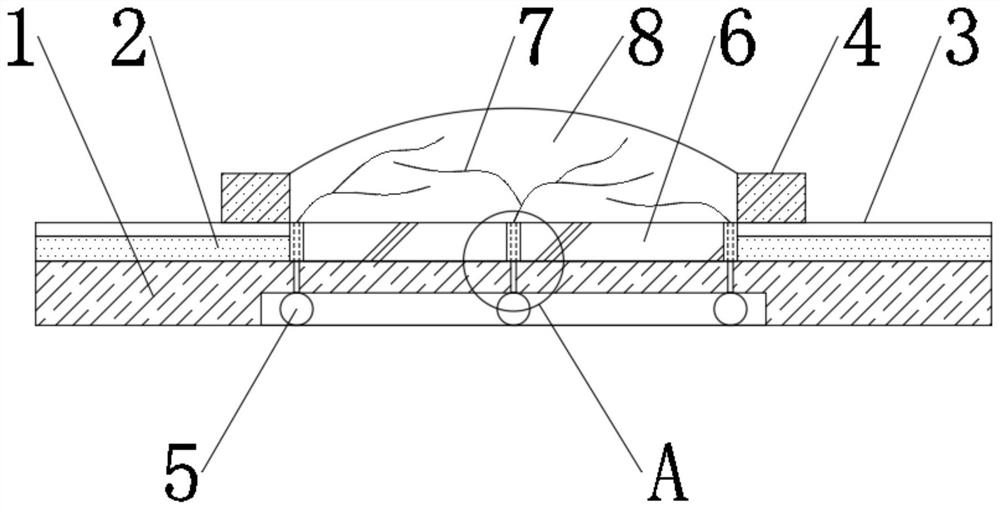

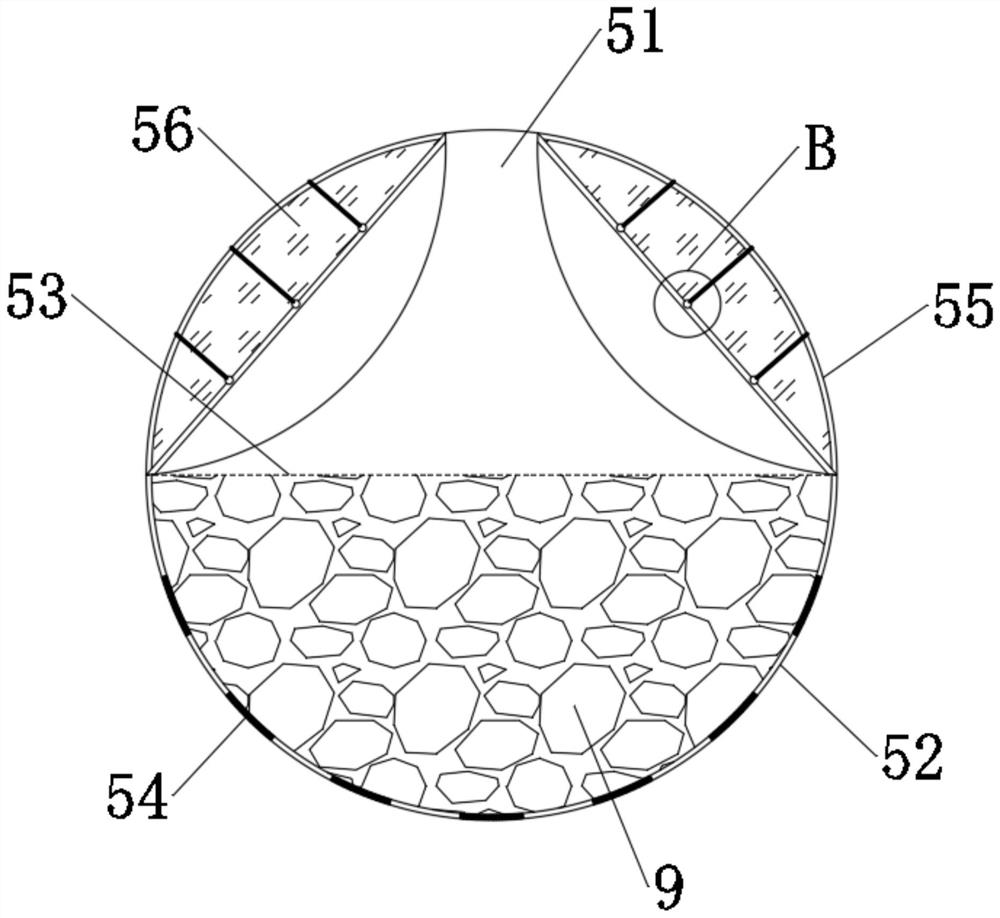

[0043] see figure 1 , a LED circuit board with a COB packaging substrate, comprising a metal substrate 1, the upper end of the metal substrate 1 is connected with a hollow insulating plate 2, the upper end of the hollow insulating plate 2 is connected with a matching circuit layer 3, and the upper end of the circuit layer 3 is connected with a matching A cofferdam 4, a plurality of chips 6 are inlaid and installed in the hollow insulation board 2, white adhesive is filled between the chips 6, a heat dissipation transparent hose 7 is embedded in the white adhesive, and a fluorescent tube 7 is filled in the cofferdam 4 The powder rubber block 8 and the lower end of the metal substrate 1 are provided with a heat exchange tank matching the chip 6, and a plurality of water supply balls 5 connected with the heat dissipation transparent hose 7 are arranged in the heat exchange tank.

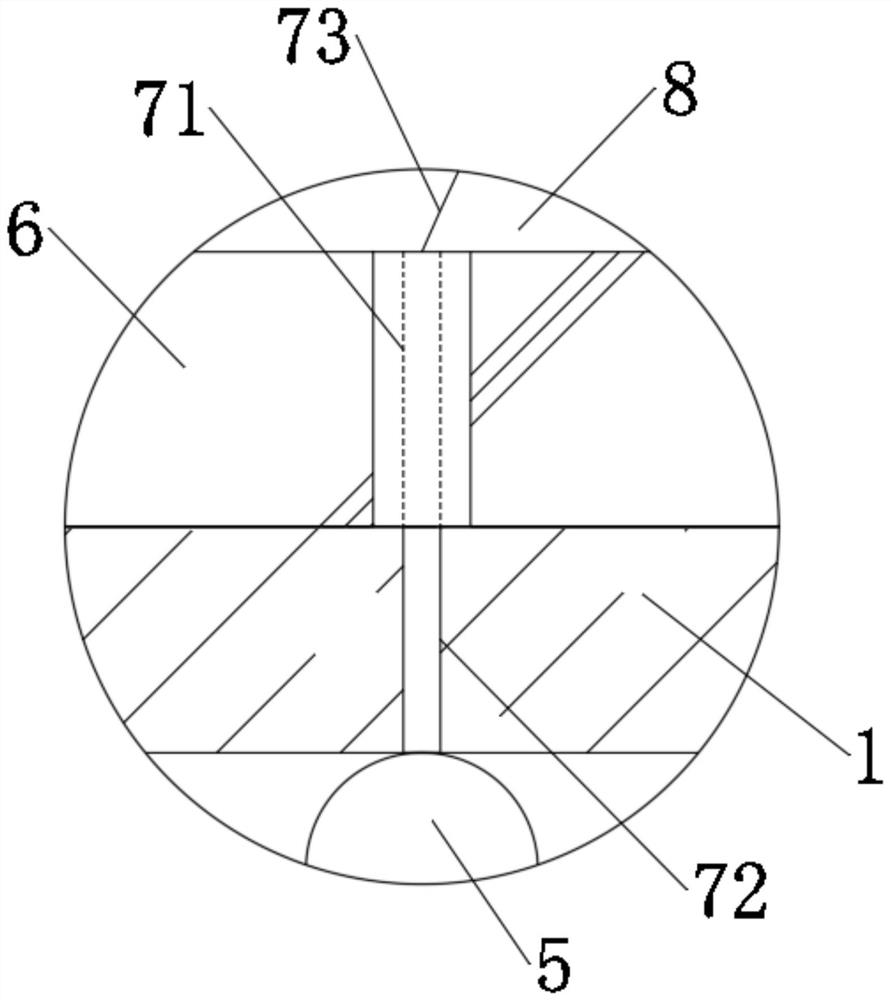

[0044] see figure 2 The heat dissipation transparent hose 7 includes a middle pipe 71, a tail pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com