A proton membrane electrocatalytic flue gas desulfurization and denitrification device

A desulfurization and denitrification, proton membrane technology, applied in the field of proton membrane electrocatalytic flue gas desulfurization and denitrification devices, can solve the problems of difficult control of limestone amount, high investment and operation costs, high operating costs, etc., achieve good product recovery and reuse effect, reduce Investment and operating costs, the effect of low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

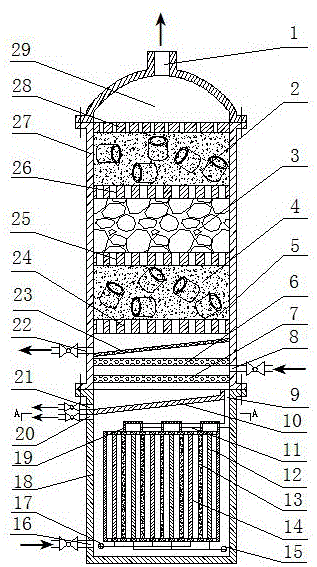

[0037] A proton membrane electrocatalytic flue gas desulfurization and denitrification device. Such as figure 1 As shown, the device is composed of a catalytic reaction absorption tower and an electrolytic reactor, and the lower end of the catalytic reaction absorption tower and the upper end of the electrolytic reactor are connected with the central line as a whole.

[0038] The structure of the catalytic reaction absorption tower is as follows: figure 1 As shown: the top cover 29 and the tower body 5 are fixedly connected to the center line through the flange, the longitudinal section of the top cover 29 is arc-shaped, and the center of the top cover 29 is provided with an exhaust port 1 .

[0039] The structure of tower body 5 is as figure 1 As shown: the tower body shell 27 is a hollow cylinder, and the height and outer diameter ratio of the tower body shell 27 is 3:1~4:1. Inside the tower shell 27, there are baffles 28, a first desulfurization and denitrification catal...

Embodiment 2

[0053] A proton membrane electrocatalytic flue gas desulfurization and denitrification device. Except following technical parameter, all the other are with embodiment 1:

[0054] The height and outer diameter ratio of the tower shell 27 is 4:1~5:1.

[0055] The ratio of the height to the outer diameter of the electrolytic reactor shell 18 is 1.2:1~1.3:1.

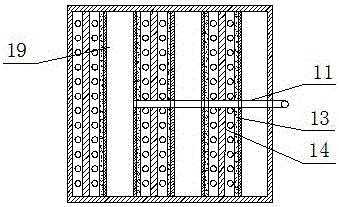

[0056] The electrolytic reaction chamber is in the shape of a box, and there are 15 slots uniformly opened on the inner wall of the top plate, bottom plate, front side plate and rear side plate of the box body, and each slot is in the shape of a “mouth”. The plane where the two slots are located is parallel to the left side panel of the cabinet. Proton membranes 13 are embedded in slots with even numbers, anode plates (14) are embedded in slots with sequence numbers 1, 5, 9 and 13, and cathode plates 12 are embedded in the remaining slots. A row of small holes is evenly opened between the slots on the bottom plate of the ...

Embodiment 3

[0058] A proton membrane electrocatalytic flue gas desulfurization and denitrification device. Except following technical parameter, all the other are with embodiment 2:

[0059] The electrolytic reaction chamber is in the shape of a box. There are 19 slots evenly opened on the inner wall of the box top, box bottom, box front side plate and box rear side plate. Each slot is in the shape of a "mouth". The plane where the two slots are located is parallel to the left side panel of the cabinet. Proton membranes 13 are embedded in slots with even numbers, anode plates 14 are embedded in slots with sequence numbers 1, 5, 9, 13 and 17, and cathode plates 12 are embedded in the remaining slots. The upper plane of the top plate of the box body is provided with 5 strip groove plates 19 .

[0060] This device can treat SO in the mixed flue gas 2 , NO X and CO 2 Purification can also recycle sulfur and methanol resources in the product. The specific steps are as follows:

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com