Self-unloading punch press

An automatic unloading and punching technology, applied in metal processing equipment, stripping devices, feeding devices, etc., can solve the problems of high labor dependence and low production efficiency, and achieve reduced labor dependence, low cost, and automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

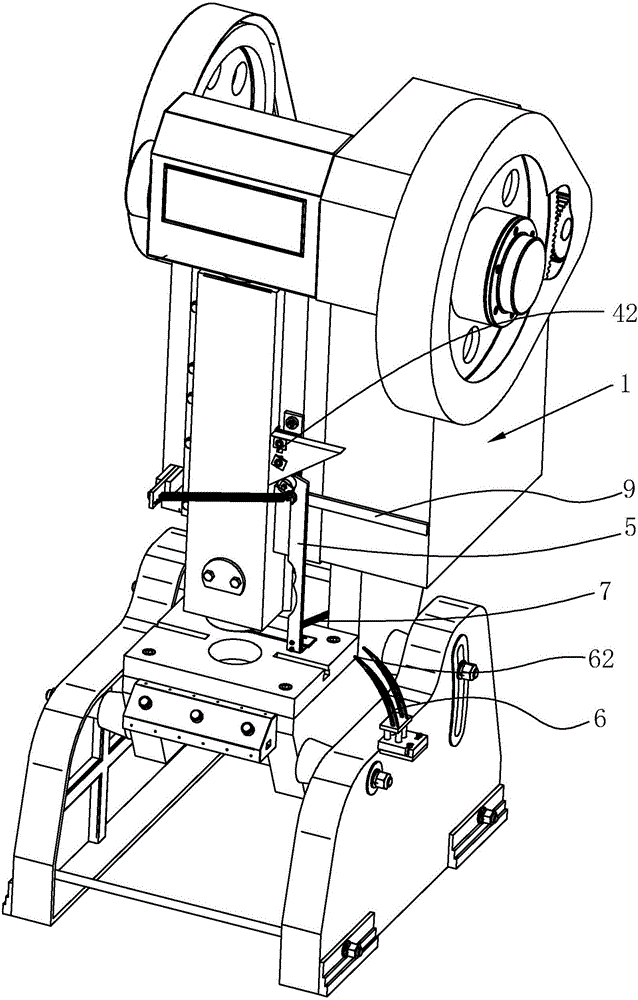

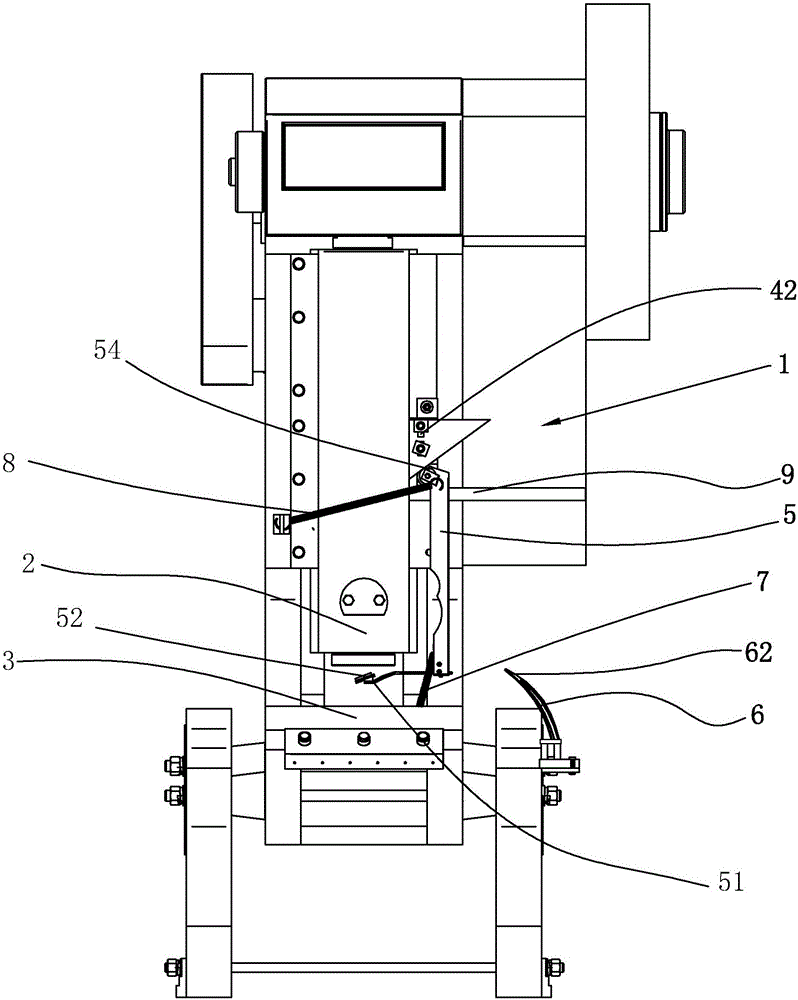

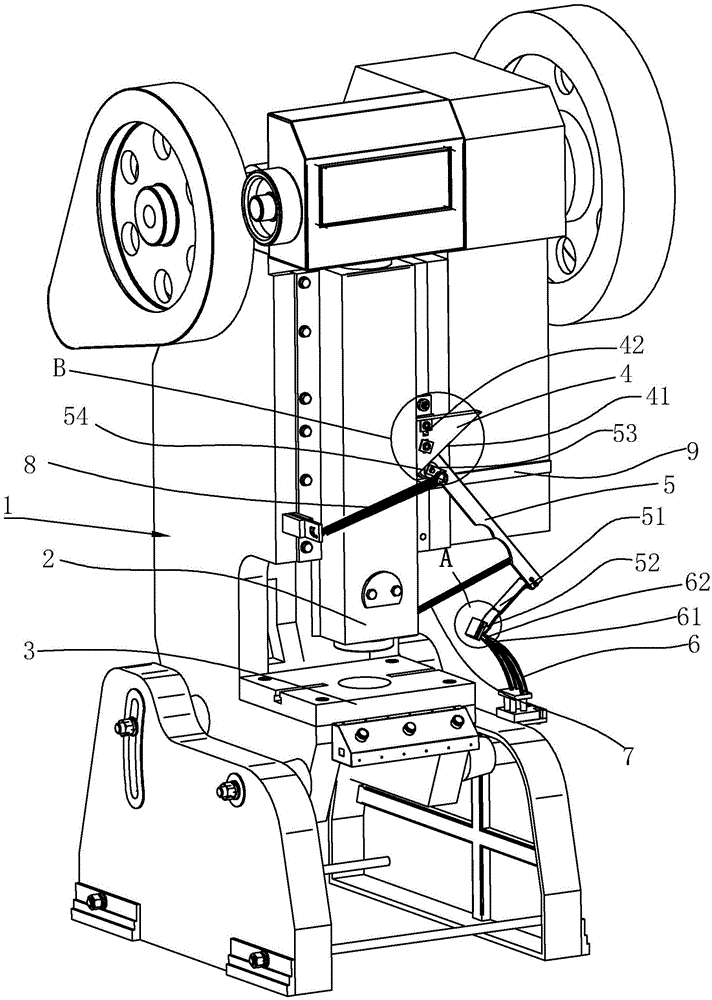

[0024] refer to Figure 1 to Figure 5 The embodiment of the automatic unloading punch press of the present invention will be further described.

[0025] An automatic unloading punching machine, the main motor drives the flywheel, and the clutch drives the gear, crankshaft, connecting rod, etc. to achieve the linear motion of the slider. The movement from the main motor to the connecting rod is a circular motion. Touch base or lower mold base 3 is installed the mold that will process product, when metal strip passes through, the material of the metal strip in the present embodiment is iron, or the alloy of iron, makes the workpiece after finishing can be processed The pick-up part 52 sucks, and the mold clamping just can realize punching, forming, blanking and other purposes.

[0026] The working process of the automatic unloading punching machine is as follows: 1. The feeder 10 intermittently feeds the corresponding length of metal strip to the stamping station; The workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com