Diesel locomotive adopting traction mode of flex-coil spring side bearing and low-level diagonal draw bar

A technology of internal combustion locomotives and inclined rods, which is applied to locomotives with internal combustion engines, locomotives with gas turbines, locomotives, etc., to achieve good working results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the drawings.

[0029] Best embodiment:

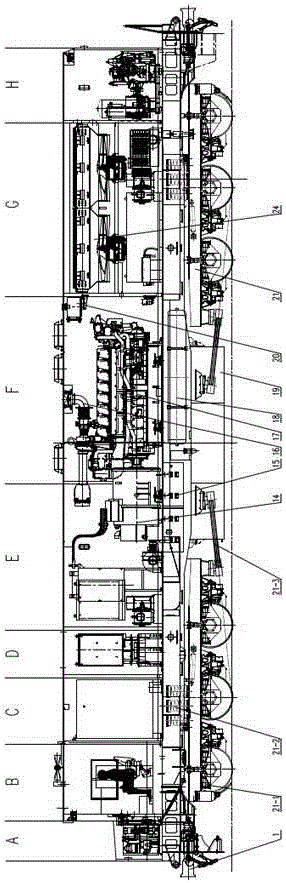

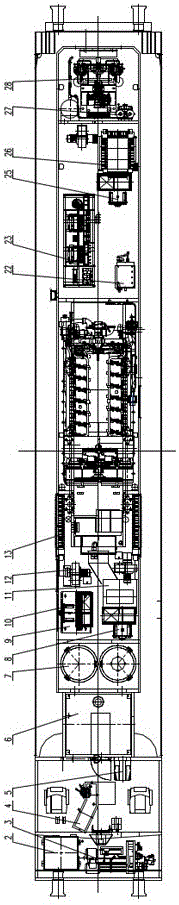

[0030] Such as figure 1 , 2 As shown, a diesel locomotive adopting a high-circular spring side bearing and a low-position oblique tie rod traction method is divided into a car body, a frame, and a bogie from top to bottom, and the car body is divided into a front engine room from front to back. A. Driver's cab B, electrical room C, resistance brake room D, clean air room E, power room F, cooling room G and auxiliary room H. There are main air cylinder 18 and battery box 15 on both sides of the middle of the frame. A bogie 21 is provided at both ends of the lower part of the frame. The middle of the lower part of the frame is a fuel tank 19 and a traction pin. The bogie 21 is a two-series suspension bogie, including a frame body, wheels, a series of damping springs and The secondary damping spring, the wheel is arranged under the frame, the primary damping sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com