Circuit breaker assembly line and controlling method thereof

A circuit breaker assembly and assembly line technology, which is used in the manufacture of conveyor control devices, emergency protection devices, circuits, etc., can solve the problems of no longer suitable for modular circuit breaker assembly, complex structure, and complex assembly, so as to improve assembly efficiency, The effect of running lightly and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

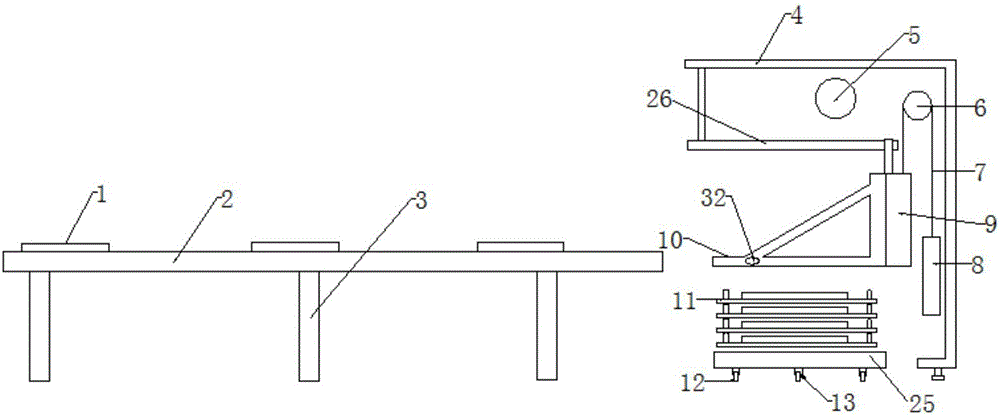

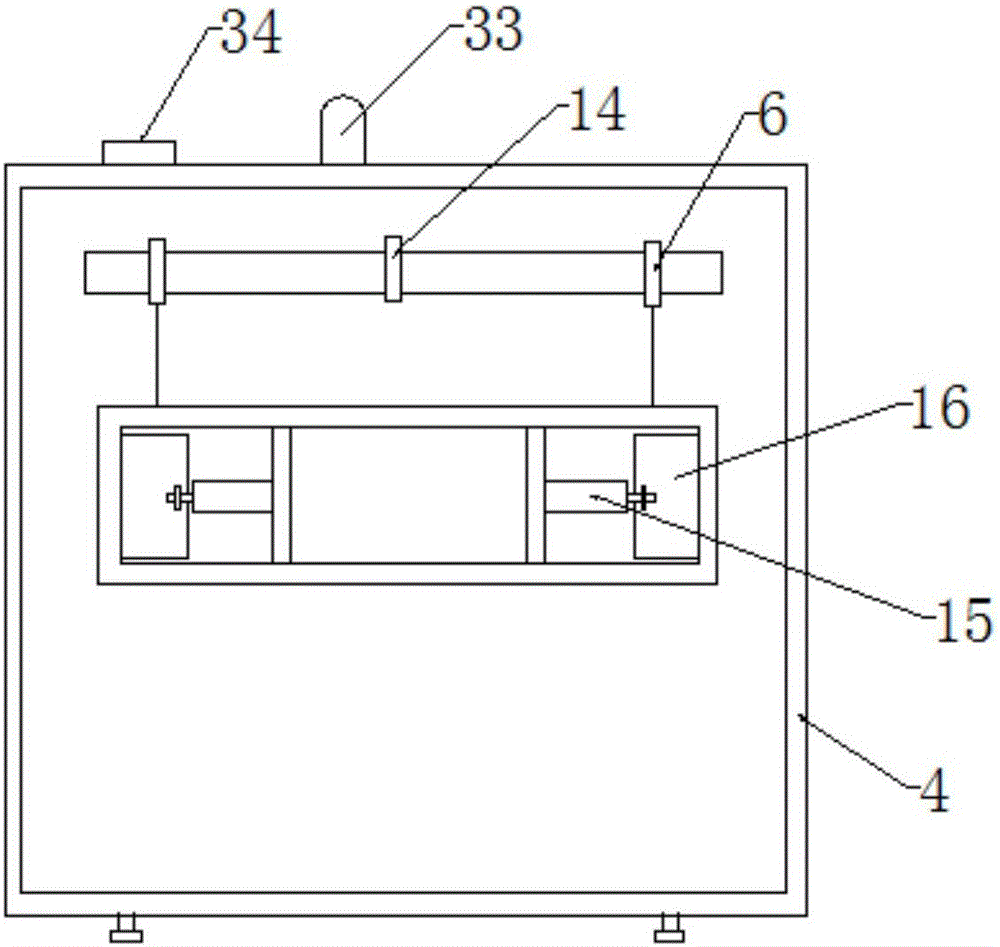

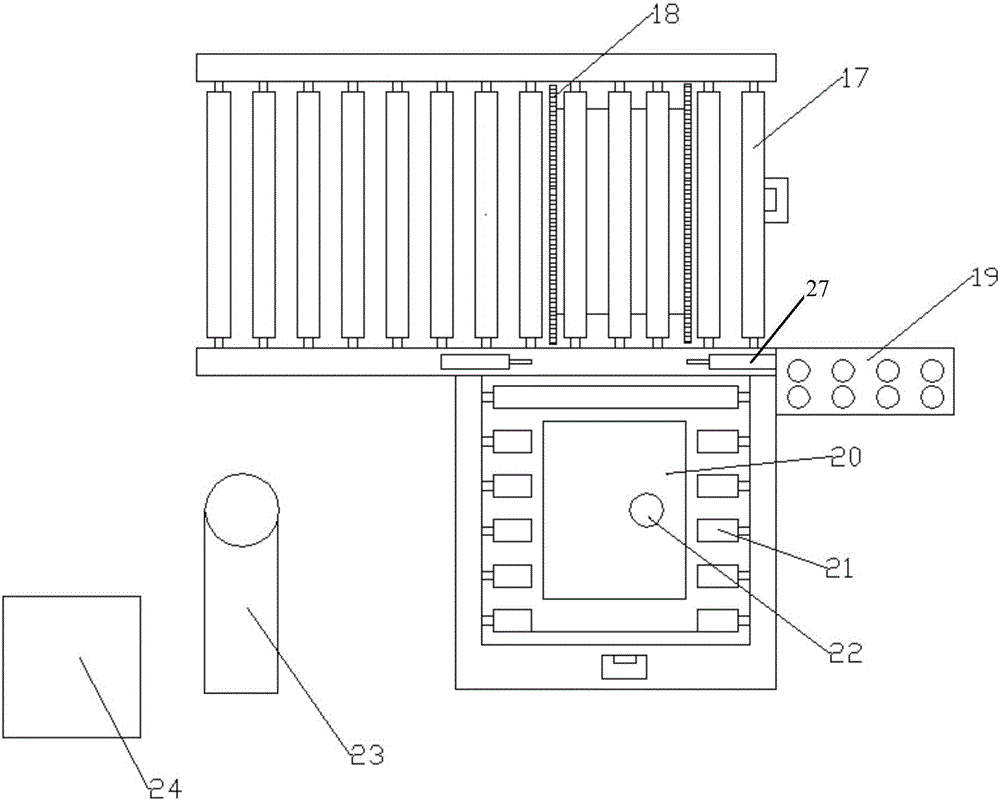

[0040] figure 1 It is a side view of the assembly line in the present invention. It can be seen from the figure that the circuit breaker assembly line includes a lifting device and a conveying device. body 4 is a cuboid frame, the outer surface is covered with a transparent material), and the delivery device includes two parallel mechanical arms 10 for grasping the assembly frame 11, one end of the two mechanical arms 10 faces the transmission device, and the other end is connected to the hanging The frame 9 is connected, and the hanger 9 is connected with the first elevating mechanism for lifting the mechanical arm 10. A telescopic cylinder 15 for horizontally opening the mechanical arm 10 is arranged between the mechanical arm 10 and the hanger 9, and the upper part of the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com