On-line washing process of work-over operation oil pipe and oil pumping rod

A technology for sucker rods and oil pipes, which is applied in the fields of oil field workover oil pipes and sucker rod cleaning. It can solve the problems that anti-seepage cloth cannot be handled, affects crude oil production, and environmental pollution. Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

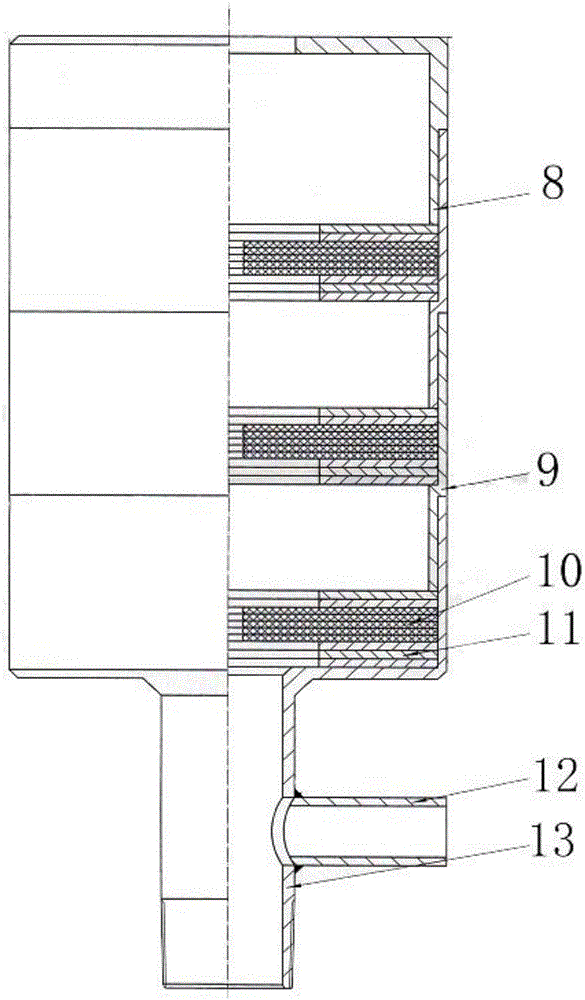

[0011] The present invention will be further described below in conjunction with accompanying drawing:

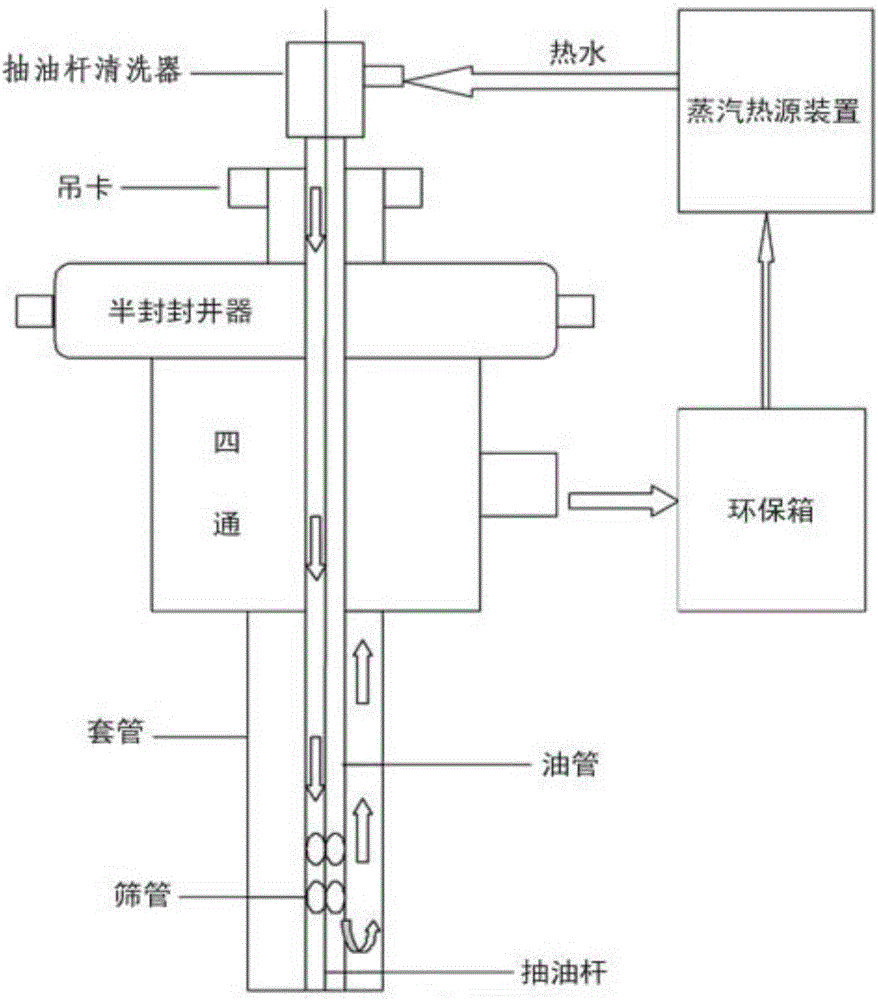

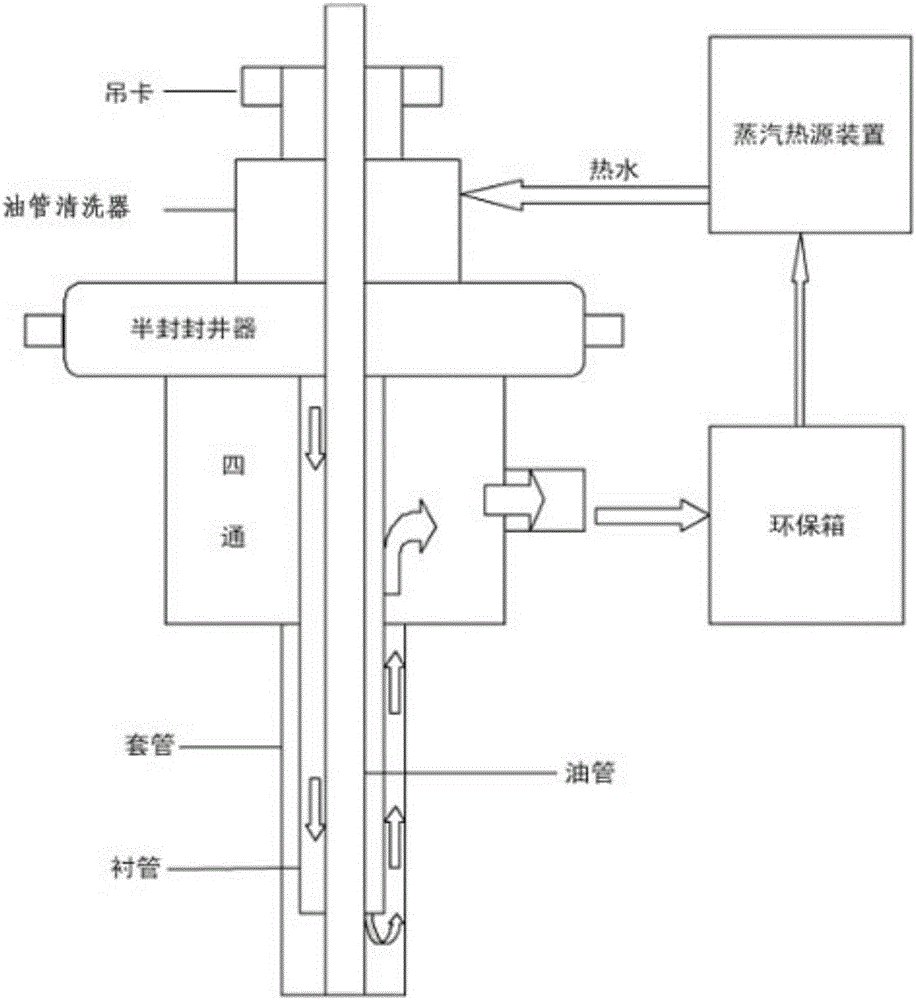

[0012] This application uses the operating well overflow as the cleaning cycle medium, uses the negative pressure pump of the environmental protection box to suck the overflow into the environmental protection box, and then uses the discharge pump of the environmental protection box to transport it to the steam heat source device, and passes through the pipe rod wellhead cleaner after rapid heating Inject into the annular space of the oil casing, use high-temperature liquid to completely dissolve the oil and wax on the oil well pipe and rod, and enter the environmental protection box for recirculation with the overflow of the operating well, and the cleaned oil and wax are gradually recycled into the environmental protection box, and the operation After completion, it will be re-injected to the oil return line through the environmental protection box. The cleaning process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com