Protective coal seam and unmanned thin coal seam mining method

A mining method and thin coal seam technology, applied in ground mining, mining equipment, earthwork drilling, etc., can solve problems such as roof fall, poor working environment, and increase the difficulty of mining protective layers, and achieve the effect of preventing impact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

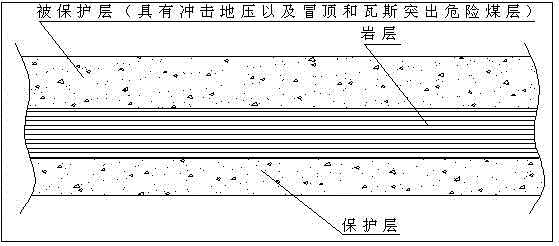

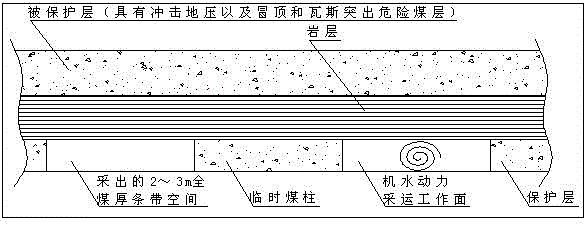

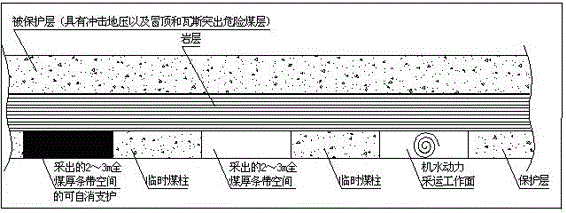

[0017] Such as figure 1 , 2 , 3, 4, and 5, a coal mining method with self-contained support of the present invention is to effectively support the goaf during mining, provide effective space for coal mining operations, relieve roof impact pressure and prevent roof Caving; After mining, the support body is controlled to gradually dissolve on its own according to the needs of the coal mining process, so that the overlying strata in the mining area can be slowly and uniformly settled and unloaded, so as to effectively prevent rock burst and sudden large-scale gas gushing.

[0018] A coal mining method that realizes the purpose of the present invention with self-contained support is: new degradable solid support materials and fluids are injected into the closed space to expand and solidify the support; after the coal pillars on both sides of the support body are mined, a ventilation space can be formed After coal mining, under the action of roof pressure and weathering, the solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com