Shield advancing and hinging system

An articulated system and shield technology, applied in mining equipment, earth-moving drilling, tunnels, etc., can solve problems such as low efficiency of oil cylinders, and achieve the effect of improving efficiency, saving energy, and reducing working strokes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

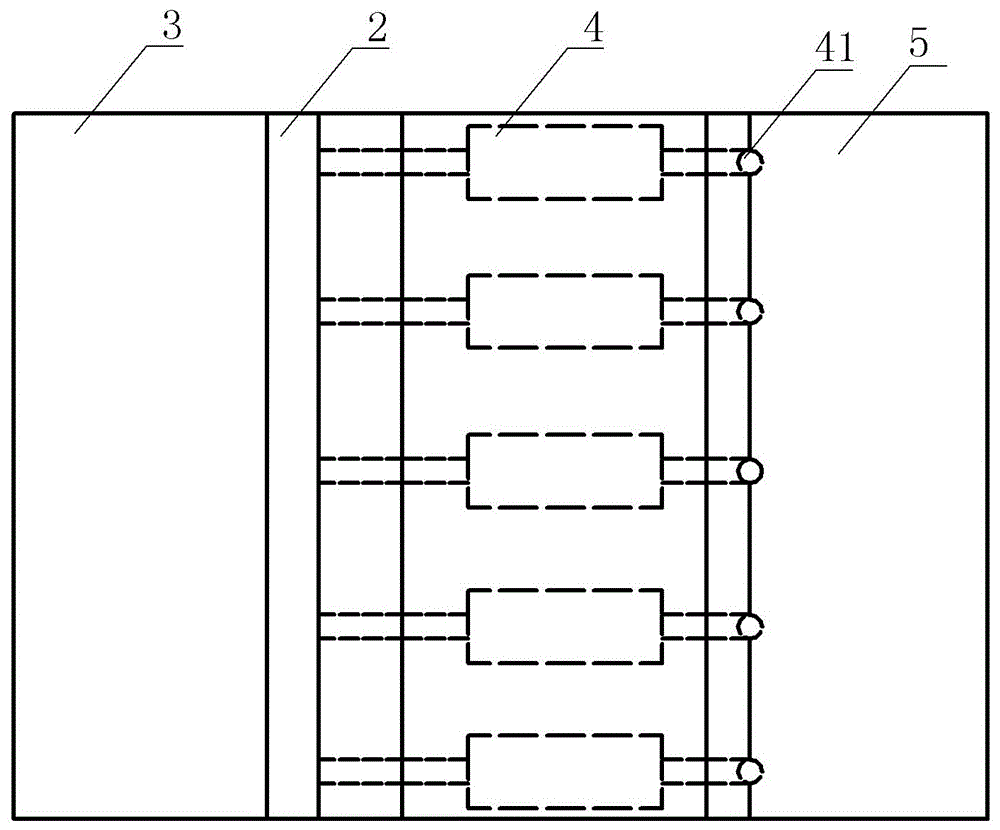

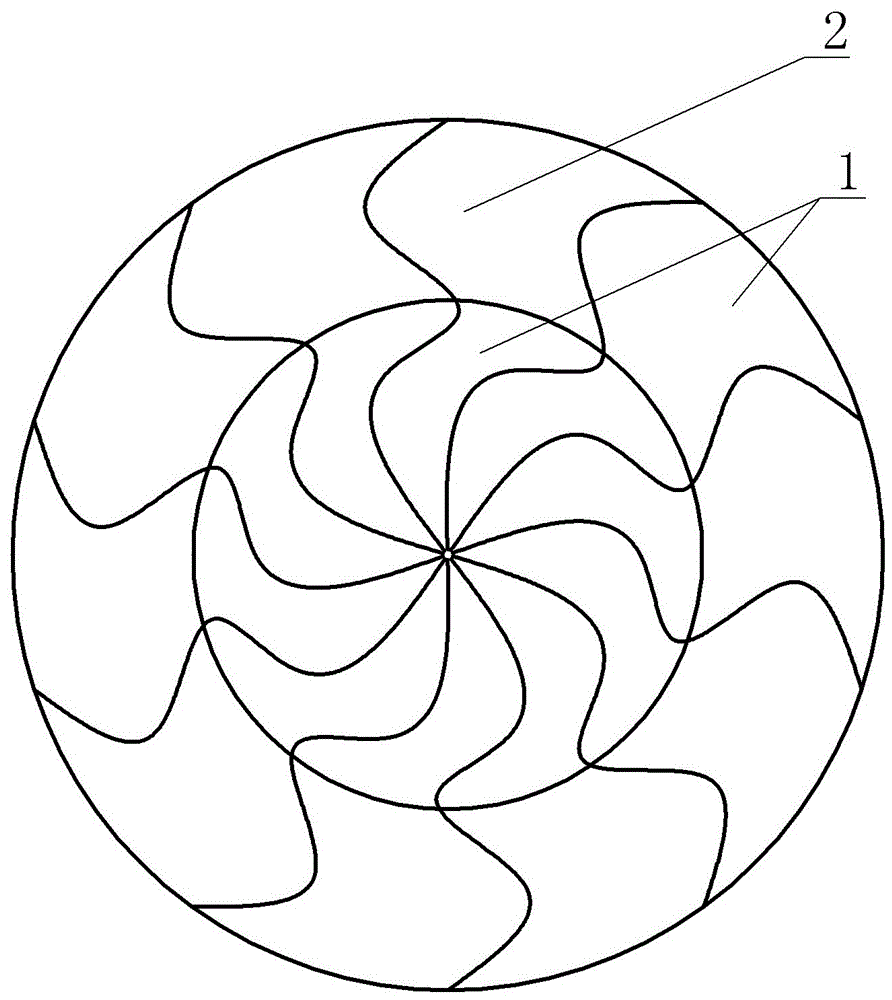

[0014] The reference signs in the drawings of the description include: supporting plate 1 , working plane 2 , front shield 3 , double-acting hydraulic cylinder 4 , back shield 5 , and hinge 41 .

[0015] The embodiment is basically as attached figure 1 , figure 2 Shown: Shield propulsion and articulation system, including 10 double-acting hydraulic cylinders 4, 10 single-acting hydraulic cylinders, the maximum stroke of the single-acting hydraulic cylinders is 2150mm;

[0016] The double-acting hydraulic cylinder 4 and the single-acting hydraulic cylinder are evenly distributed in the middle shield and are distributed parallel to each other in concentric circles. The double-acting hydraulic cylinder 4 is located on the outside, and the single-acting hydraulic cylinder is located on the inside. The middle shield is embedded and fixed There are 10 stepped holes for fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com