Automatic continuous reaction cup loading device for chemiluminescence immunoassay

A technology of chemiluminescence immunoassay and loading device, which is applied in the field of automatic continuous loading device for cuvette for chemiluminescence immunoassay, can solve the problem of affecting the operation efficiency of chemiluminescence immunoassay, lack of efficient and simple automatic loading device, complicated mechanical design and circuit control, etc. problems, to achieve the effect of simple and easy daily maintenance, reducing the intensity of manual work, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

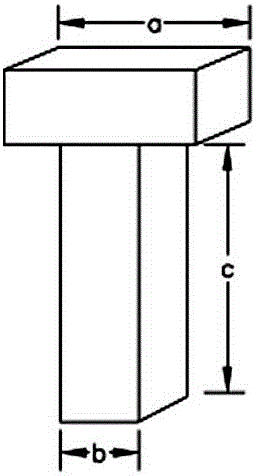

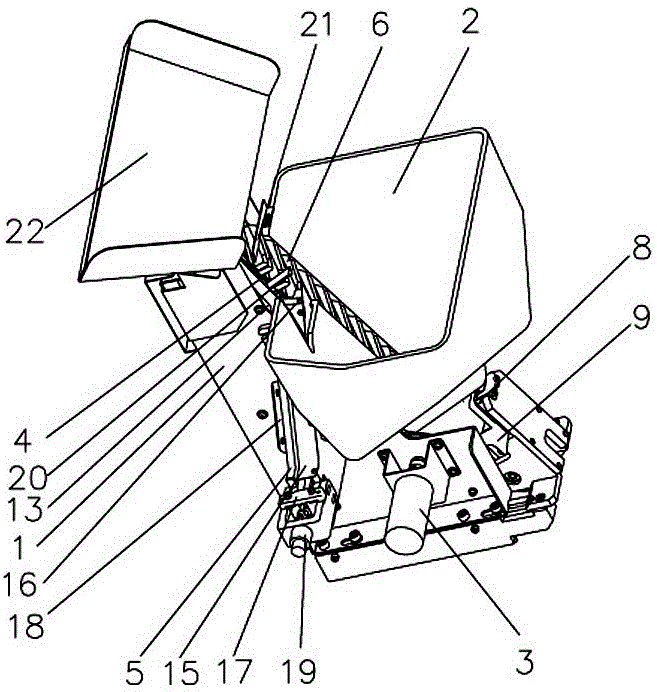

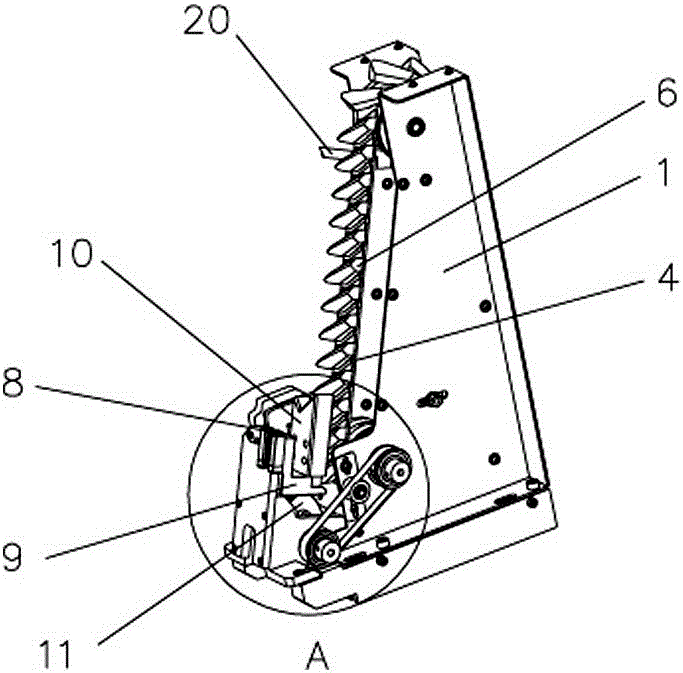

[0023] like Figure 2-7 As shown, the cuvette automatic continuous loading device for chemiluminescence immunoassay of the present invention includes a rack 1 and a cuvette container 2 arranged on the rack 1, a lifting conveyor belt 4 driven by a motor 3, and a The slideway 5 at the outlet of the side of the conveyor belt 4, the lifting conveyor belt 4 is stuck at the opening of the rear wall of the cuvette container 2 and runs through the bottom of the cuvette container 2, and a plurality of slides to the cuvette container are arranged at intervals on the lifting conveyor belt 4. The lifting block 6 is inclined in the direction of the track 5, and the bottom of the slideway 5 is provided with a groove 7 whose width is greater than the width b of the cuvette body and smaller than the width a of the cuvette mouth.

[0024] The motor 3 is located on the motor bracket at the bottom of the frame 1, and is connected with the driving roller shaft below the lifting conveyor belt 4 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com