Three-dimensional stereo high-density film multi-layer capacitor and preparation method thereof

A three-dimensional, multi-layer capacitor technology, used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of complex integration point container technology, and achieve the effect of simple process, high reliability, and reduced capacitor size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

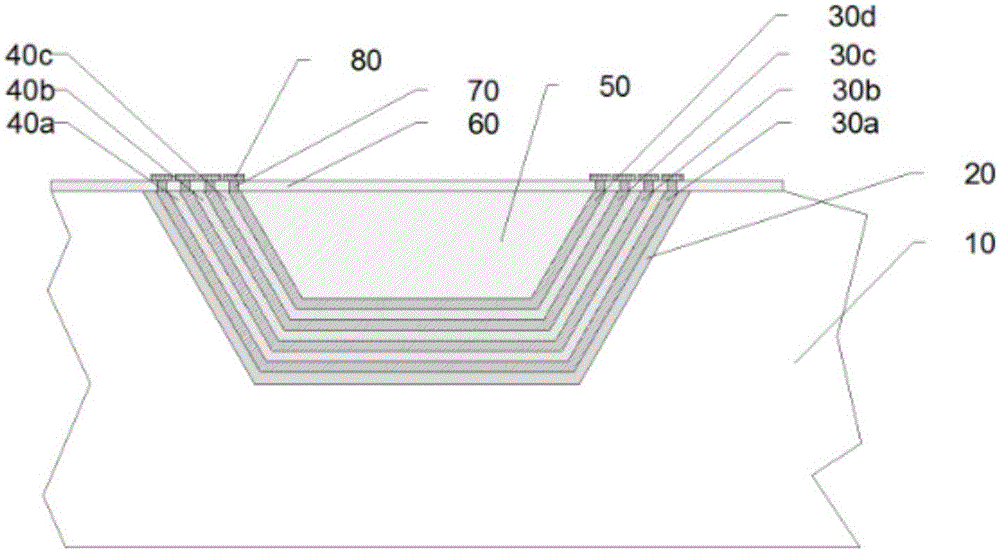

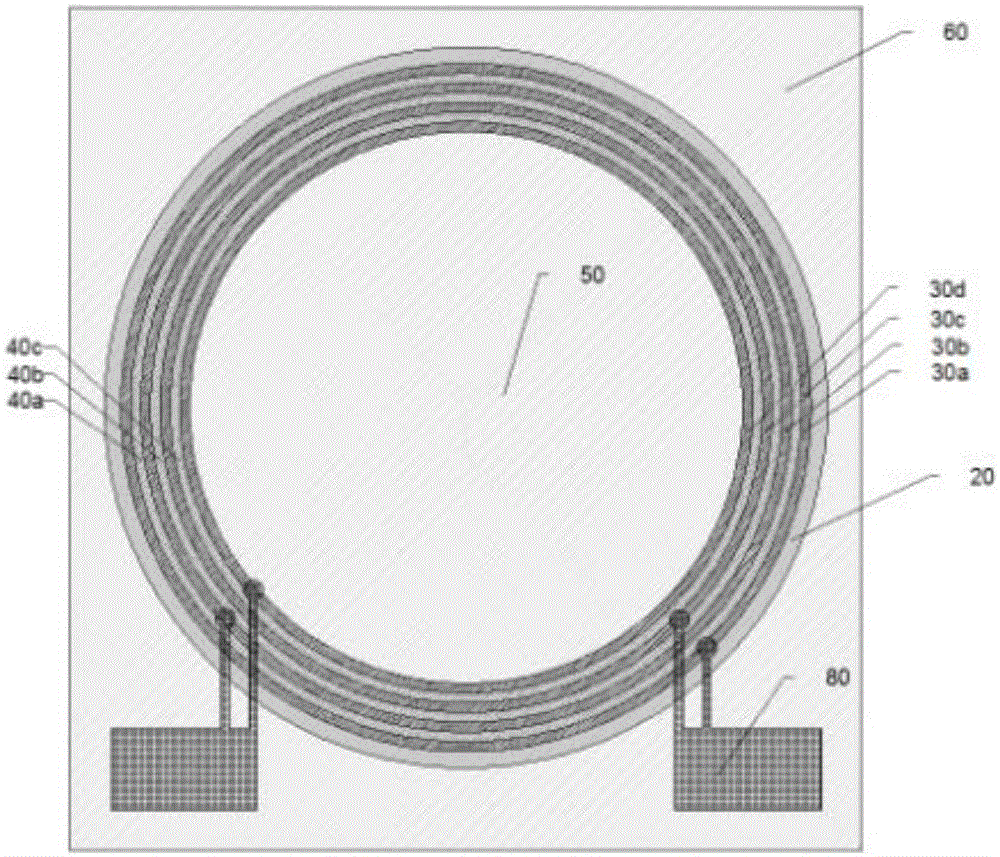

[0033] The invention provides a three-dimensional high-density thin-film laminated capacitor, which comprises a substrate, an insulating film, a multilayer capacitor functional layer film, an insulating layer, an insulating passivation layer, a metal connecting layer, and an electrode plate. The multi-layer capacitor functional layer film is covered with an insulating passivation layer, and the electrode plates are respectively connected with the conductive plate films of the capacitor.

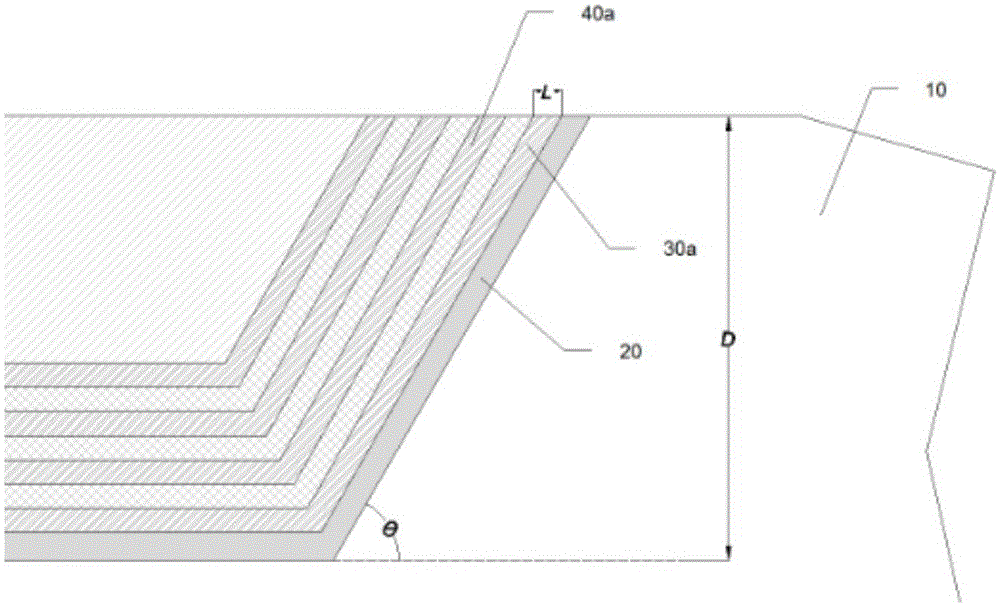

[0034] Such as figure 1 As shown, the upper surface of the substrate 10 is etched with conical pits, extending longitudinally to expand the surface of the substrate. An insulating film 20 is deposited on the upper surface of the conical pit. A multilayer capacitive functional layer film is deposited above the insulating film 20, and the multilayer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com