Warming junction-pushing diffusion technology

A diffusion process and heating rate technology, applied in the field of solar cells, can solve the problem that the gettering effect of the substrate is not particularly significant, and achieve the effect of optimizing the phosphorus diffusion process, improving the gettering ability, and improving the gettering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

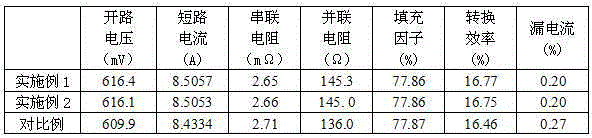

Examples

Embodiment 1

[0021] The specific steps of the temperature-rising push-junction diffusion process are as follows:

[0022] (1) START. The time is 10s, the temperature is 780°C, and the maximum nitrogen flow rate is 8L / min.

[0023] (2) Enter the boat. The time is 650s, the temperature is 780°C, the maximum nitrogen flow rate is 8L / min, and the speed of entering the boat is 400mm / min.

[0024] (3) Heat up. The time is 600s, the temperature is 780°C, and the maximum nitrogen flow rate is 18L / min.

[0025] (4) Pre-oxidation. The time is 500s, the temperature is 780°C, the maximum nitrogen flow rate is 16L / min, and the oxygen flow rate is 2L / min.

[0026] (5) deposition. The time is 1000s, the temperature is 790~810°C, the maximum nitrogen flow rate is 15.9L / min, the small nitrogen flow rate is 1.4L / min, and the oxygen flow rate is 0.7L / min.

[0027] (6) Push the knot. The time is 600s, the temperature is 830~860°C, and the maximum nitrogen flow rate is 18L / min.

[0028] (7) cooling. ...

Embodiment 2

[0032] The specific steps of the temperature-rising push-junction diffusion process are as follows:

[0033] (1) START. The time is 5s, the temperature is 780°C, and the maximum nitrogen flow rate is 8L / min.

[0034] (2) Enter the boat. The time is 700s, the temperature is 780°C, the maximum nitrogen flow rate is 8L / min, and the speed of entering the boat is 300mm / min.

[0035] (3) Heat up. The time is 700s, the temperature is 780°C, and the maximum nitrogen flow rate is 20L / min.

[0036] (4) Pre-oxidation. The time is 500s, the temperature is 780°C, the maximum nitrogen flow rate is 18L / min, and the oxygen flow rate is 2L / min.

[0037] (5) deposition. The time is 1000s, the temperature is 790~810°C, the large nitrogen flow rate is 17L / min, the small nitrogen flow rate is 1.5L / min, and the oxygen flow rate is 1.5L / min.

[0038] (6) Push the knot. The time is 600s, the temperature is 830~860°C, and the maximum nitrogen flow rate is 20L / min.

[0039] (7) cooling. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com