A kind of preparation method of fd mature kiwi fruit in situ slice

A technology for kiwifruit slices and kiwifruit, which is applied in the field of in-situ slice preparation of FD mature kiwifruit, can solve the problems of loss of nutrients, the glass layer hinders the sublimation of water, and the original taste of mature kiwifruit cannot be guaranteed, and the effect of improving the degree of hardening is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

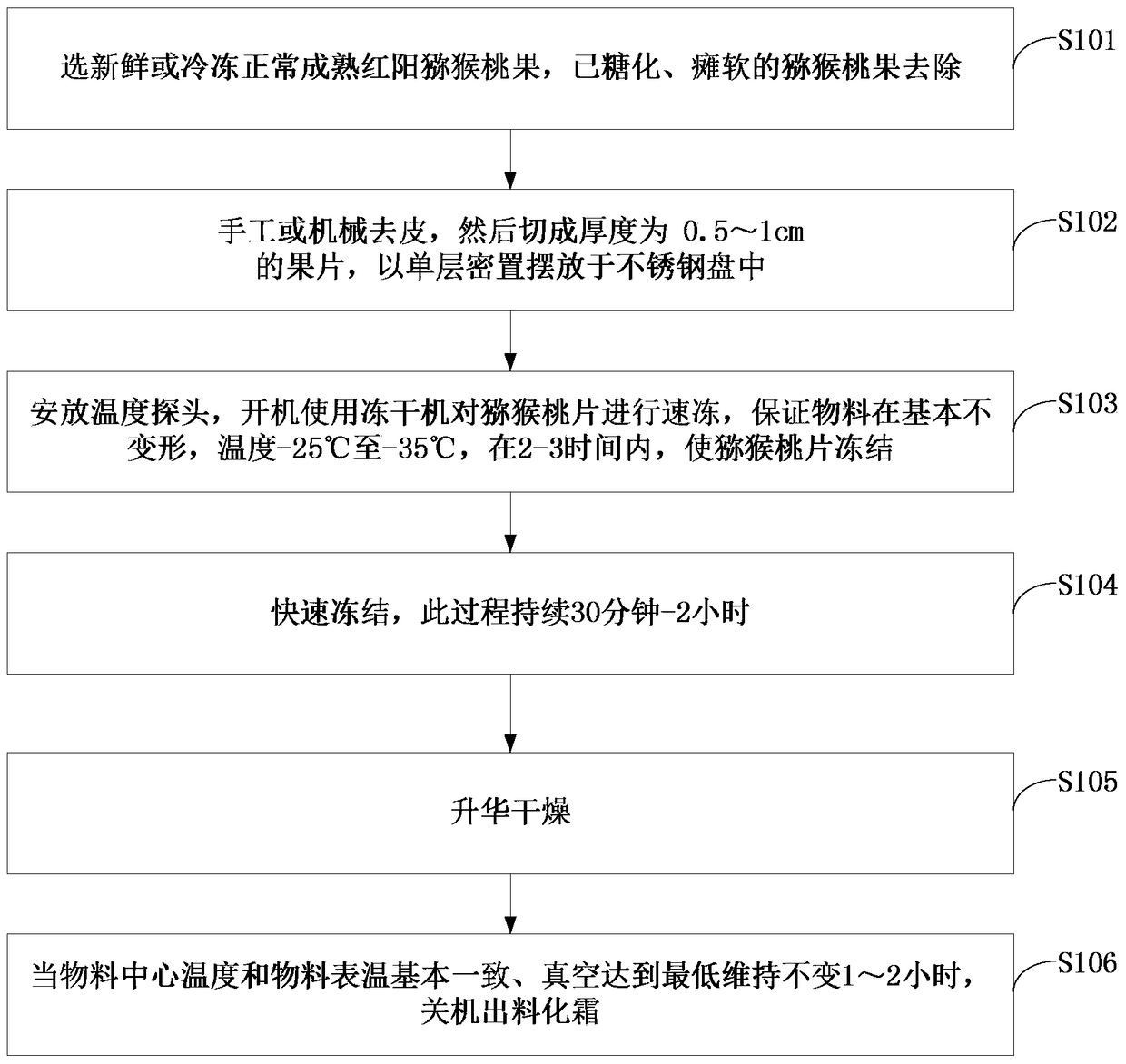

[0027] The present invention is achieved in this way, a kind of FD mature kiwi fruit in-situ sheet preparation method comprises:

[0028] S101. Select fresh or frozen normally ripe Hongyang kiwi fruit, and remove the saccharified and limp kiwi fruit;

[0029] S102. Peel the fruit manually or mechanically, then cut into fruit slices with a thickness of 0.5-1 cm, and arrange them in a single layer in a stainless steel plate;

[0030] S103, place the temperature probe, start the machine and use the freeze dryer to quickly freeze the kiwi slices to ensure that the material is basically not deformed, and the temperature drops from room temperature to -25°C to -35°C within 2-3 hours, so that the kiwi slices are frozen;

[0031] S104, quick freezing, this process lasts for 30 minutes to 2 hours;

[0032] S105, sublimation drying;

[0033] S106. When the temperature of the center of the material is basically the same as that of the surface of the material, and the vacuum reaches the...

Embodiment 1

[0039] Embodiment 1 takes Hongyang kiwi fruit as an example, and the steps are the same as before.

[0040] The beneficial effects of the present invention are as follows:

[0041] 1. The kiwi slices can maintain the prototype: the kiwi slices are frozen by rapid cooling and conduction, maintaining the support between the cells, and the vacuum is kept in sync with the heating and sublimation. When the vacuum opens a little cell gap, the fast-conducting radiant heat makes the moisture in the cell gap quickly Sublimation, because the vacuum degree is constant, the sublimation saturated vapor pressure is constantly saturated. The vapor pressure is the pressure of the gas on the liquid surface when the liquid evaporation and gas condensation rates are equal. The more evaporation, the more saturated (equilibrium) gas phase, and the liquid surface The pressure (vapor pressure) is greater. Under airtight conditions, the greater the water vapor pressure, the more volatile it is. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com