Phase-change temperature control type fuel assembly for non-combustion type low temperature cigarette and preparing method thereof

A low-temperature cigarette, phase change temperature control technology, applied in the direction of smoker's products, applications, tobacco, etc., can solve the problems of complex components and structures of combustible heat sources, reduced correlation, complex composition and process, etc., to achieve improved combustion and safety performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

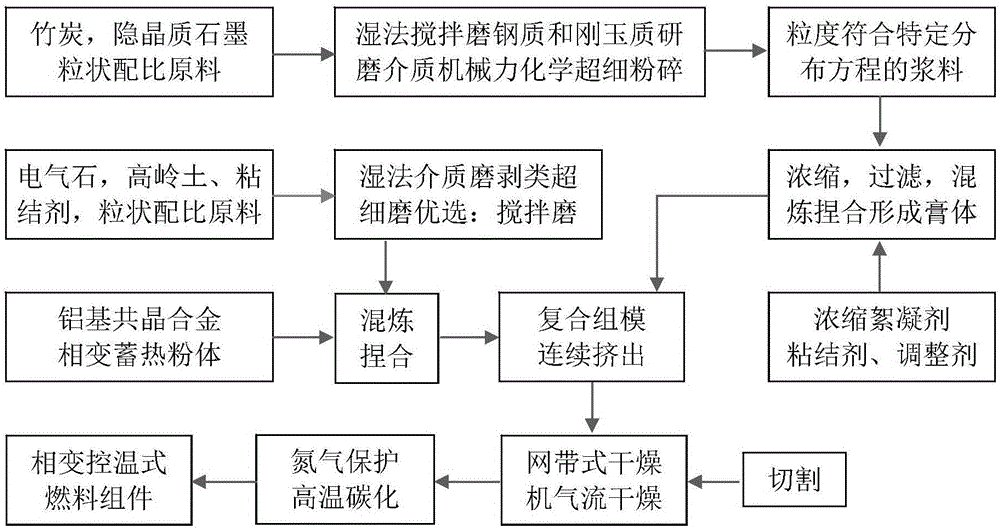

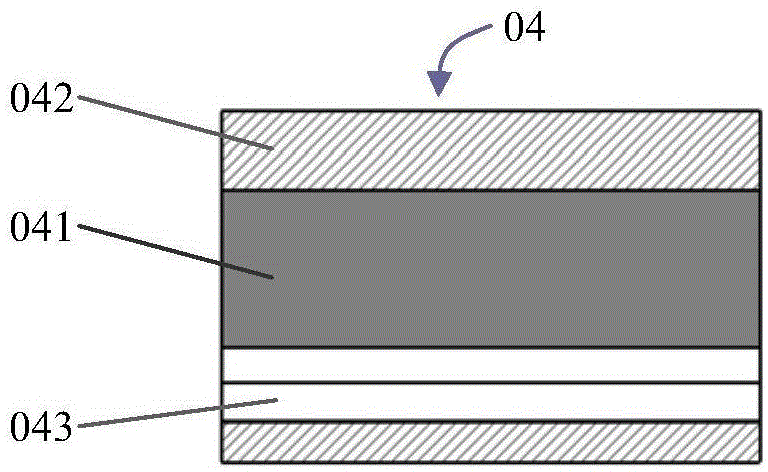

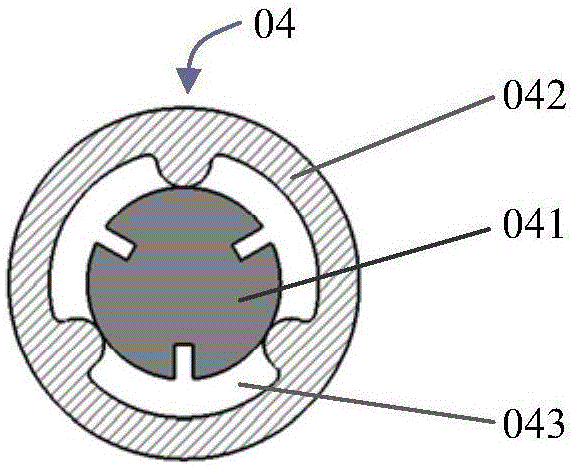

[0119] The process flow of the preparation method of the phase-change temperature-controlled fuel assembly for non-combustible low-temperature cigarettes of the present invention is as follows: figure 1 As shown, the prepared phase-change temperature-controlled fuel assembly 04, 05 or 06 axial and cross-sectional exemplary cross-sectional views are as follows Figure 2a , Figure 2b , Figure 3a , Figure 3b or Figure 4a , Figure 4b As shown, the specific method for preparing a phase-change temperature-controlled fuel assembly for non-combustible low-temperature cigarettes includes the following steps:

[0120] The first step, carbonaceous raw material paste preparation

[0121] (1) Proportion of carbonaceous raw materials (mass percentage): Various carbonaceous raw materials can be used, preferably, bamboo charcoal 50% to 95%, particle size less than 150 μm, fixed C content not less than 95%, exothermic peak starting temperature The range is 310-325°C, the end tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com