Efficient and full-automatic steam generation device

A technology of a steam generating device and a steam generator, which is applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of low safety factor, single quality control, simple automation settings, etc., and achieve stable safety measures and moisture content. The effect of less and stable steam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

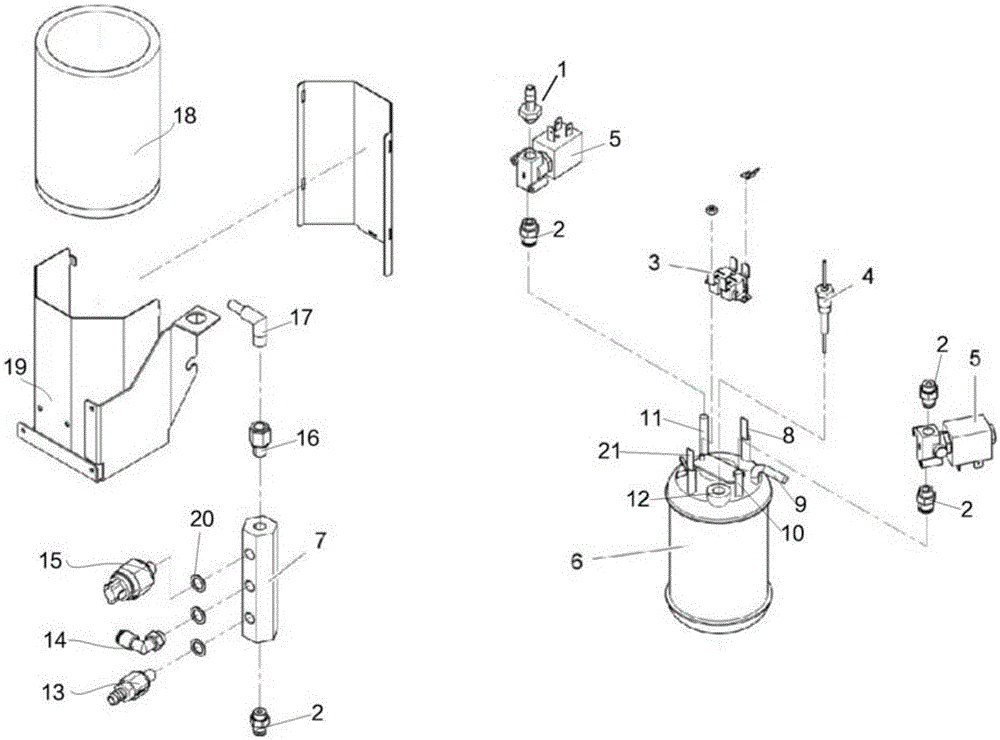

[0043] Such as figure 1 As shown, a high-efficiency full-automatic steam generating device includes Green connector 1, four push-in connectors 2, two temperature sensors 3 (such as figure 1 As shown, two temperature sensors 3 are close to each other), liquid level sensor 4, two solenoid valves 5, steam generator 6, distributor 7, heating pipe 8, distributor connecting pipe 9, water inlet 10, steam outlet 11, Liquid level sensor installation port 12, pressure adjustment switch 13, L-type quick-plug connector 14, pressure sensor 15, one-way valve 16, Green elbow 17, thermal insulation cotton 18 and fixed panel 19,

[0044] One end of the Green joint 1 and one end of the push-in joint 2 are connected to the solenoid valve 5 through threaded connection, and the other end of the push-in joint 2 is clamped with the steam outlet 11, and the steam outlet 11 is arranged on the top of the steam generator 6 and connected with the The inner cavity of the steam generator 6 communicates, ...

specific Embodiment 2

[0057] Roughly the same as specific embodiment 1, the difference only lies in:

[0058] The push-in connector 2 is a nickel-plated copper push-in connector;

[0059] The L-type push-in connector 14 is a nickel-plated copper L-type push-in connector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com