Fullerene-macromolecule composite and preparation method thereof

A fullerene and polymer technology, applied in the field of fullerene-polymer composite and its preparation, can solve the problems of high cost and material loss, and achieve the effect of solving the loss problem and saving the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

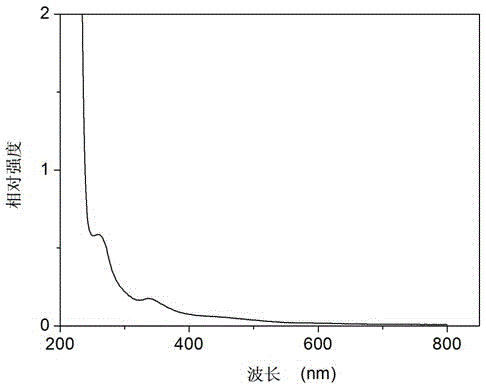

[0043] Weigh 50g of polyvinylpyrrolidone, dissolve it in 950ml of water, stir until it becomes a transparent solution, and then add 500mg of C 60 Powder, as for the ball mill tank, seal the ball mill tank well, place it in a low-temperature ball mill, set the speed at 600 rpm, and after 8 hours of operation, pour out the liquid (ball mill liquid, the same below), and centrifuge the liquid , take the upper liquid, which is the obtained C 60 - PVP complex solution. After the product was diluted, UV characterization was carried out. figure 1 C prepared for this example 60 -UV absorption diagram of the PVP complex, in the figure 340nm is C 60 The characteristic peak, the absorption peak at 450nm indicates that the two form a complex.

Embodiment 2

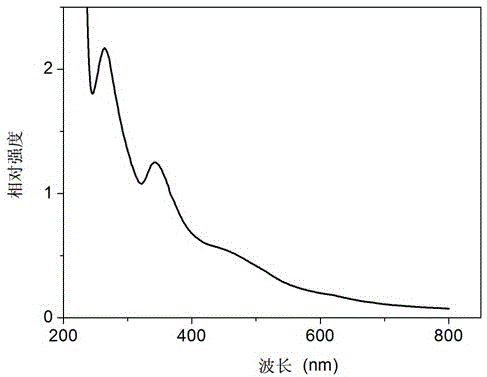

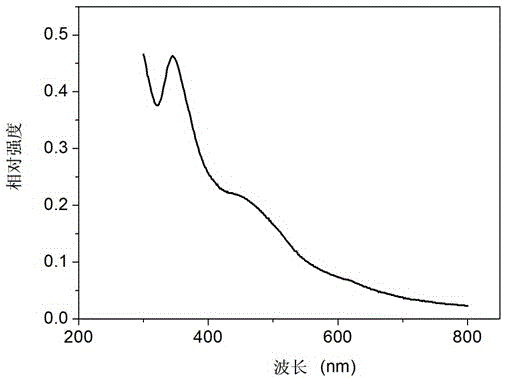

[0045]Weigh 50g of polyvinylpyrrolidone, dissolve it in 950ml of water, stir until it becomes a transparent solution, and then add 5g of C 60 Powder, as for the ball mill tank, seal the ball mill tank well, place it in a low-temperature ball mill, set the speed at 600 rpm, pour the liquid out after 10 hours of operation, centrifuge the liquid, and take the upper liquid, which is Income C 60 - PVP complex solution. After the product was diluted, UV characterization was carried out. figure 2 C prepared for this example 60 -UV absorption diagram of the PVP complex, in the figure 340nm is C 60 The characteristic peak, the absorption peak at 450nm indicates that the two form a complex.

Embodiment 3

[0047] Weigh 50g of polyvinylpyrrolidone, dissolve it in 245ml of water, stir until it becomes a transparent solution, and then add 500mg of C 60 Powder, as for the ball mill tank, seal the ball mill tank well, place it in a low-temperature ball mill, set the speed at 600 rpm, pour the liquid out after 8 hours of operation, centrifuge the liquid, and take the upper liquid, which is Income C 60 - PVP complex solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com