Method for ring rolling forming of groove inclined inner hole ring part

A ring and rolling technology, which is applied in the field of rolling and forming of inclined inner hole rings of grooves, can solve the problems of material waste, low production efficiency, and damage to metal fiber flow lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

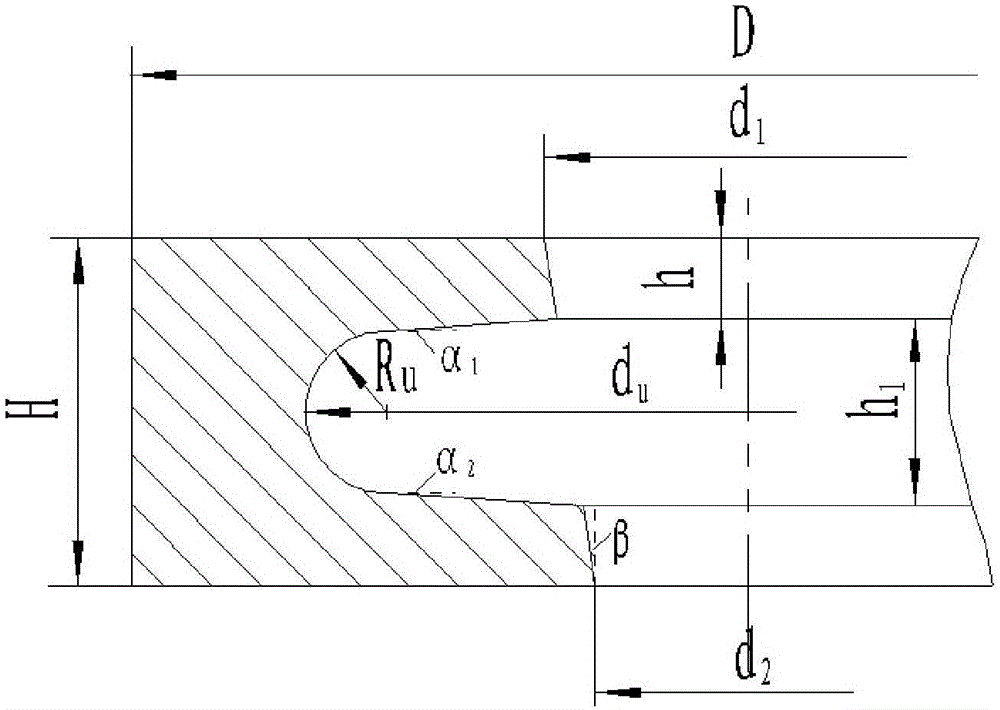

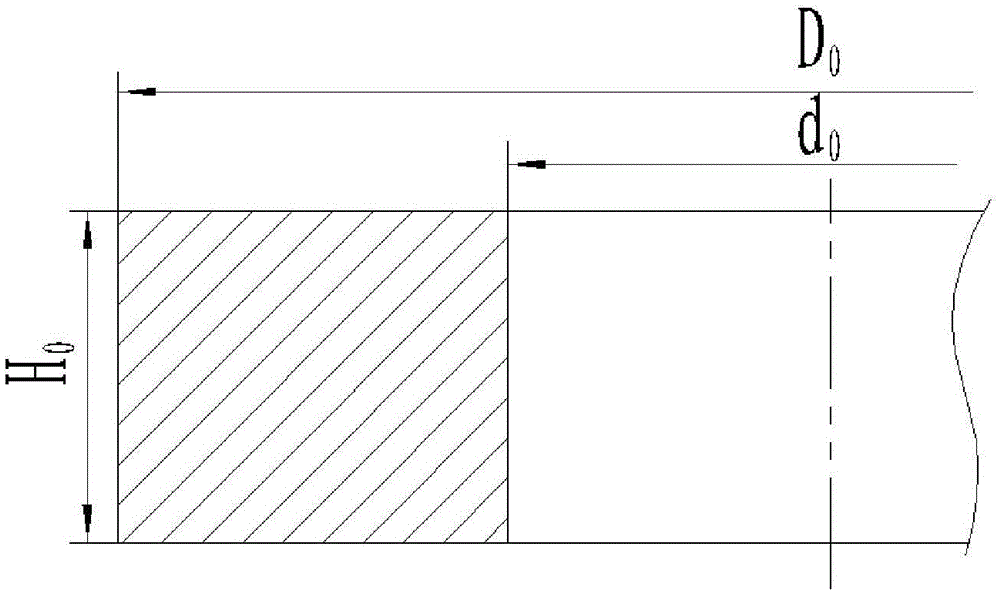

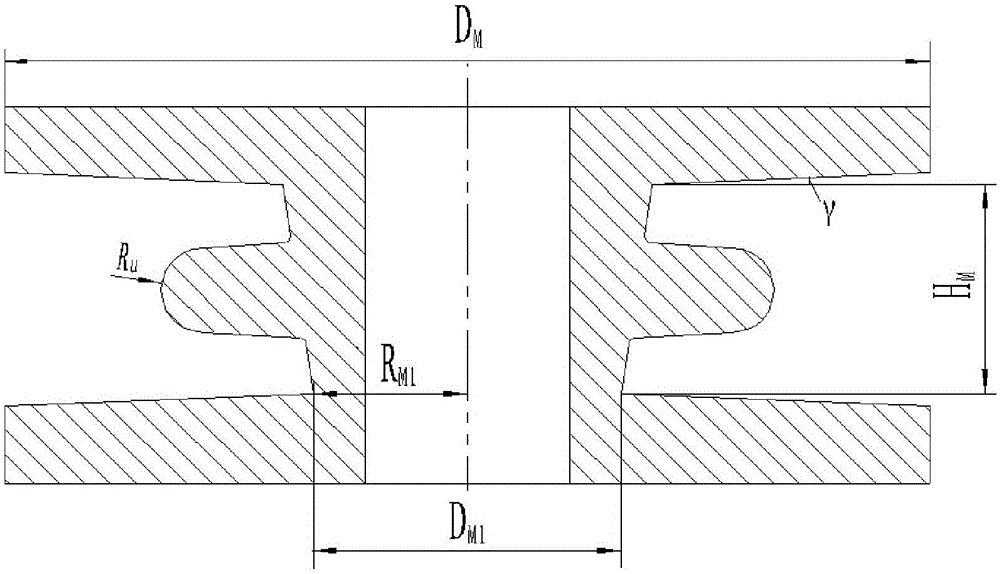

[0019] by figure 1 The ring with inclined groove and inner hole shown is a specific example, and the size of the ring with inclined inner hole in groove that is required to be rolled and expanded is: the outer diameter of the ring is D=1843mm, and the larger inner diameter of the inclined inner hole is d 1 =1715mm, the small inner diameter of the oblique inner hole d 2 =1686mm, axial height H=60mm, groove arc radius R u =12mm, the inner diameter of the groove d u =1783mm, the dimension between the outer edge of the groove and the upper and lower end faces of the ring h=15mm, the height of the outer edge of the groove h 1 =30mm, the angle α between the upper and lower inner walls of the groove and the horizontal plane 1 、α 2 are 6° and 5° respectively, and the angle β between the wall of the inclined inner hole and the axial direction of the ring is 14°; the process steps of rolling and expanding are as follows: Figure 1~5 as shown,

[0020] (1) Determine the rolling rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com