A magic color bottle cap compression molding equipment

A technology of bottle caps and equipment, which is applied in the field of magic color bottle cap compression molding equipment, can solve the problems of high defect rate, poor bonding of raw materials for two moldings, and inability to obtain different colors of magic color bottle caps, so as to improve production efficiency, The effect of high product yield and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

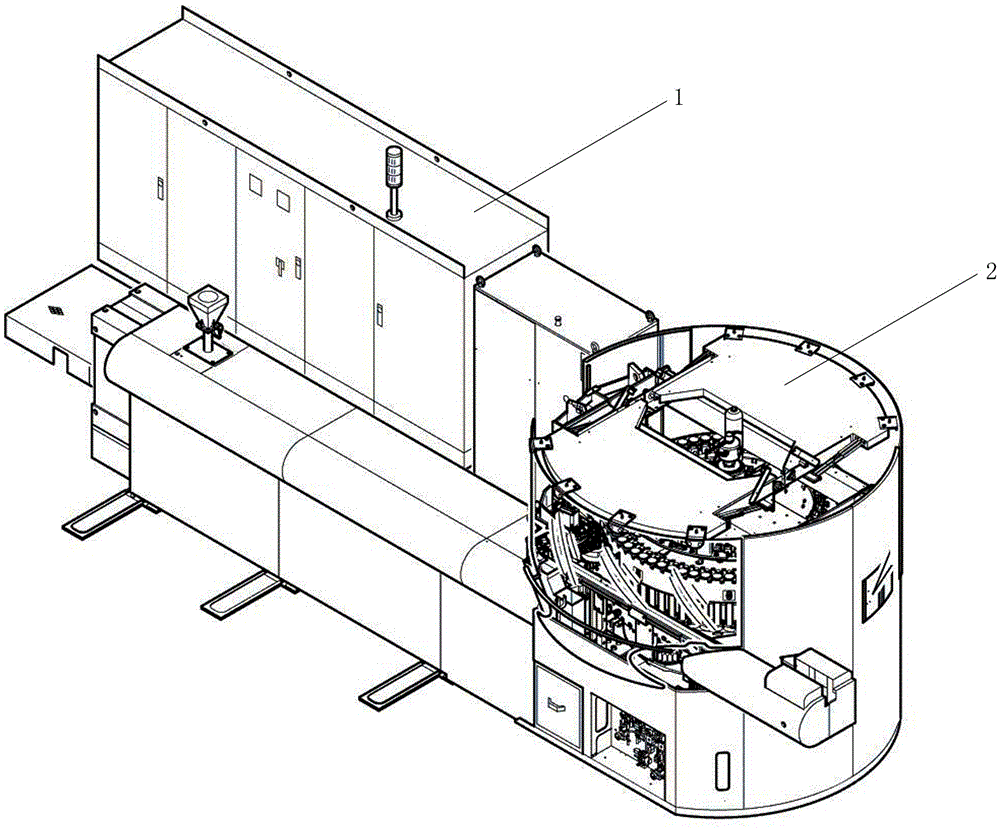

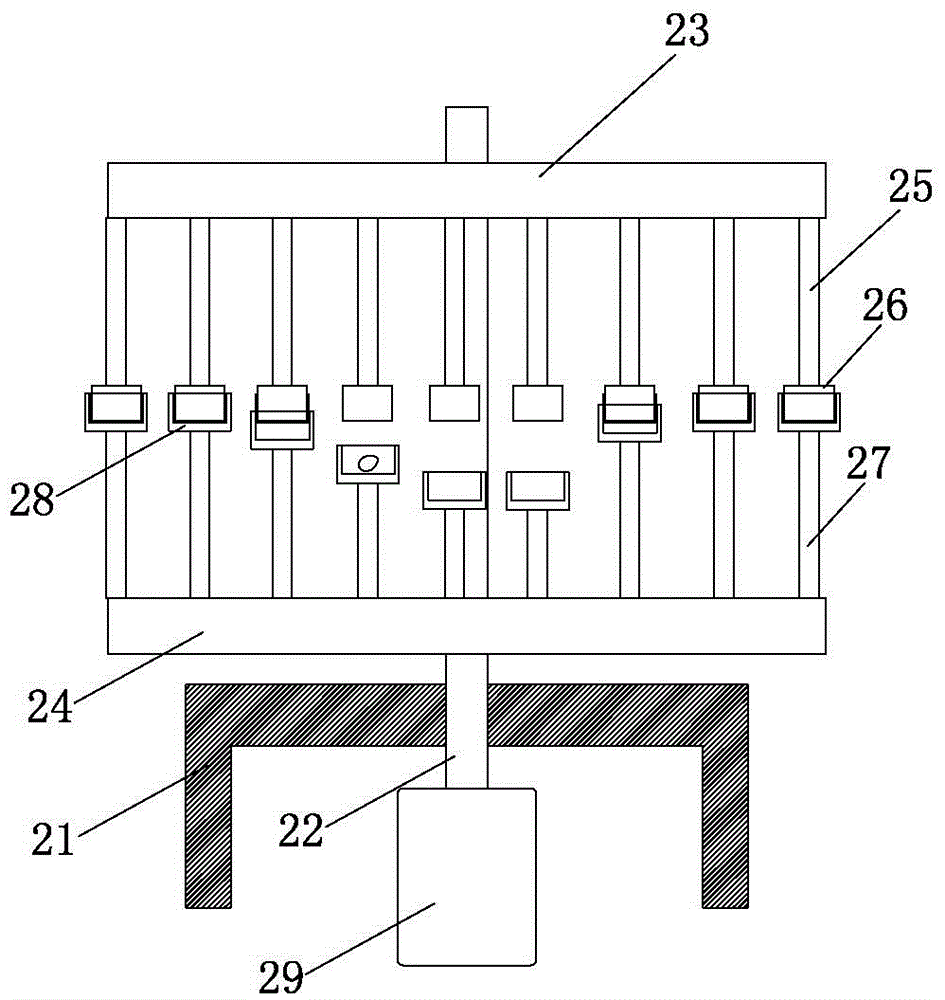

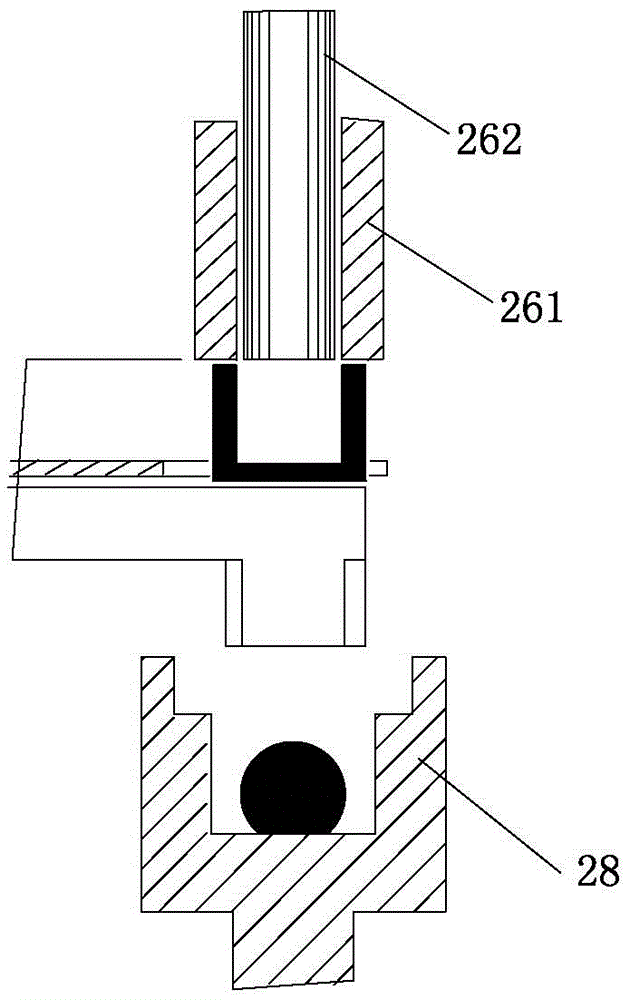

[0047] Such as Figure 1 to Figure 11As shown, the present invention is a magic color bottle cap compression molding equipment, including a machine base 1, the machine base 1 is provided with an extrusion rotating device 2, a feeding device 3, a rotating scraping device 4 and at least two extruding screws Mechanism 5, the at least two extruding screw mechanisms 5 extrude molten plastics of different colors to the feeding device 3 to meet, and the rotary scraping device 4 scrapes off the molten plastics of the feeding device 3 and sends them into the extrusion Extruded in the rotating device 2, the machine base 1 is also provided with an unloading mechanism 6 for unloading the molded products. The working principle of this equipment is: In this plan, only the blue and white magic cover is taken as an example. The two extruding screw mechanisms 5 melt the blue and white plastics, and extrude the molten plastics to the feeding device 3 respectively. Among them, the blue molten p...

Embodiment 2

[0059] Such as Figure 12 As shown, the difference between this embodiment and the first embodiment is that: the extruding screw mechanism 5 is provided with three, and a third passage 314 is also provided between the first passage 311 and the second passage 312. The molten plastics of the first channel 311 , the second channel 312 and the third channel 314 merge into the main channel 313 . This embodiment can provide the production of three colors of magic bottle caps, that is, the three extruding screw mechanisms 5 are respectively loaded with rubber particles of different colors, and melt extrusion is realized, and then three strands of molten preforms of different colors are formed. These three strands The molten blanks of different colors enter the first channel 311, the second channel 312 and the third channel 314 respectively, and finally merge in the main channel 313 to form a three-color blank, and then the three-color blank enters the nozzle 33 , the three-color bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com