A bushing trimming tool for automobile rack and pinion steering gear

A technology of automobile gear and steering gear, which is applied in the field of bushing trimming tooling for automobile rack and pinion steering gear, can solve the problems of poor control accuracy, product size is easy to fail to meet requirements, and assembly and use requirements cannot be guaranteed, so as to reduce losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

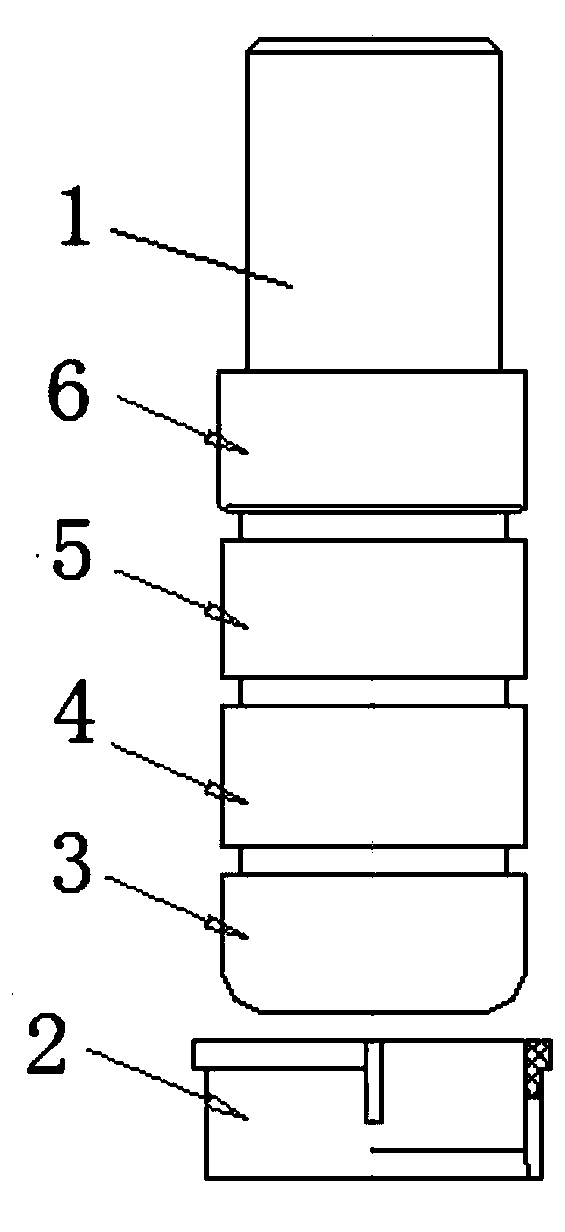

[0010] Such as figure 1 Shown is an automotive rack and pinion steering gear bush trimming tool, including a support rod 1, and the support rod 1 is sequentially provided with a guide block 3 extending into the bush 2, a secondary cutting knife 4, and a main cutting knife 5 from the top end to the tail end , Shaping grinding head 6. The guide block 3 is columnar, and its cross-sectional diameter is smaller than the inner diameter of the bushing 2 . The auxiliary cutting knife 4 is an annular cutting knife sleeved on the support rod 1 , and the diameter of the formed annular ring is larger than the inner diameter of the bushing 2 . The main cutting knife 5 is also another annular cutting knife sleeved on the support rod 1, and the diameter of the annular ring formed by it is larger than the diameter of the annular ring formed by the auxiliary cutting knife. The shaping grinding head 6 is columnar, and its cross-sectional diameter is identical with the diameter of the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com