Warehouse caking removing tool, warehouse cleaning device and material warehouse with cleaning function

A technology for removing tools and agglomerates, which is applied in the field of storage cleaning, can solve the problems of difficult to completely remove agglomerates, complicated device structure, cumbersome maintenance and other problems, and achieves the effects of avoiding personnel safety accidents, simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

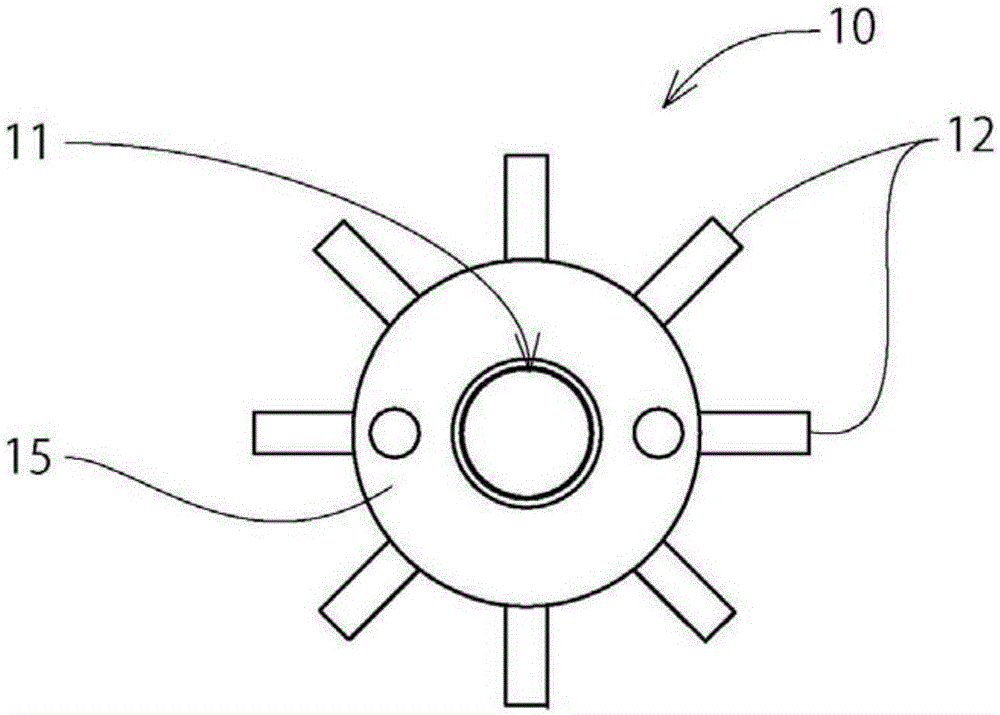

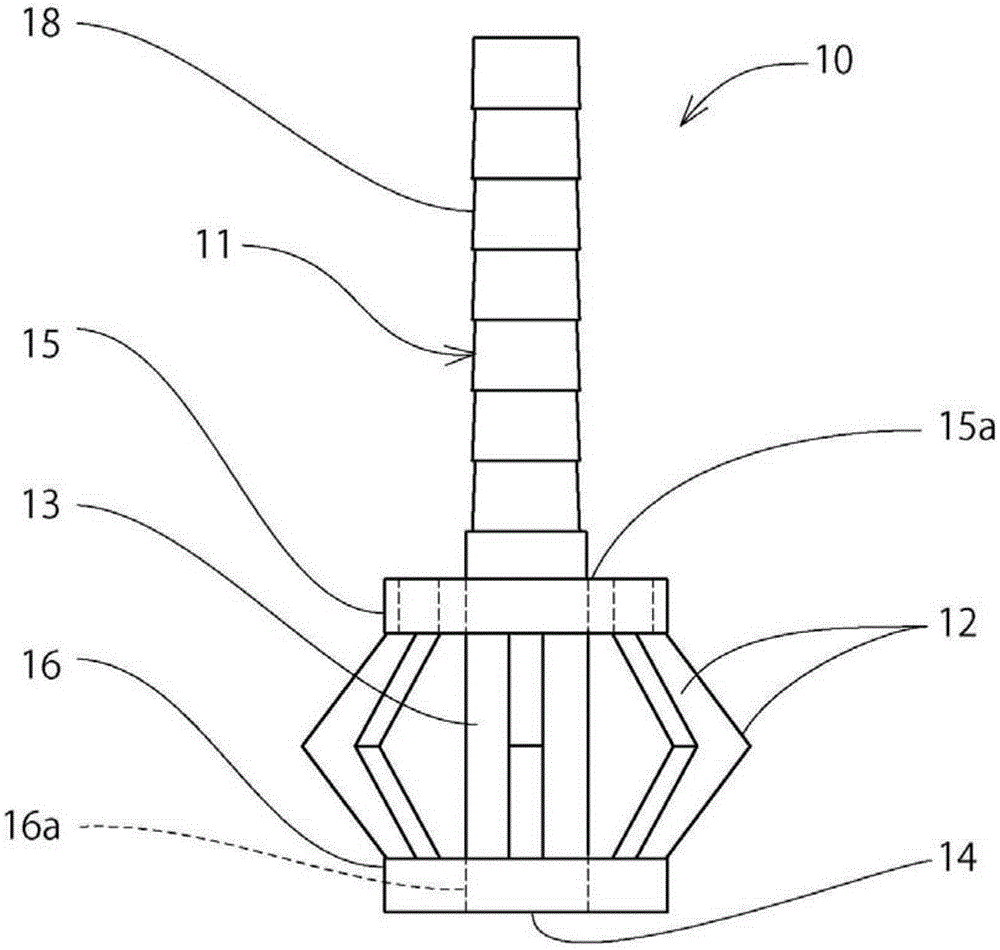

[0043] Embodiment 1 Reservoir agglomeration removal tool

[0044] figure 2 , image 3The shown reservoir agglomeration removal tool 10 is an embodiment of the present invention, mainly composed of a tubular nozzle 11 and several crushing bodies 12 with outwardly protruding structures. The nozzle 11 comprises a nozzle head 13 for spraying and a nozzle tail 18 for the delivery connection, the nozzle head 13 opening as a nozzle opening 14 . The outer circumference of the nozzle head 13 is provided with a second circular plate 15 and a third circular plate 16, and its central part has a second circular plate through hole 15a and a third circular plate through hole 16a respectively. The nozzle 11 is welded and fixed to the second circular plate 15 and the third circular plate 16 after passing through the through hole 15a of the second circular plate and the through hole 16a of the third circular plate. The crushing bodies 12 are arranged on the outer peripheral surface of the n...

Embodiment 2

[0049] Embodiment 2 The installation method of the agglomeration removal tool in the storage warehouse

[0050] When installing the storage decaking tool of Example 1, the method of connecting the compressed air supply source and the storage decaking tool is not limited. It can simply include the following steps:

[0051] ① Connect the compressed air supply source 2 to one end of the hose 3, and wrap the other end of the hose 3 around the outer circumference of the nozzle 11;

[0052] ② Use several hose straps 40 to fasten the hose 3 .

[0053] For example Figure 8 , Figure 9 As shown, one end of the hose 3 can be wrapped from the tail of the nozzle 11 of the storage agglomeration removal tool 10 to the configuration position of the first disc 15, and then fastened with a hose strap 40 to simply install it.

[0054] The above is about the installation method of the storage agglomeration removal tool in an embodiment of the present invention, but the embodiment of the pre...

Embodiment 3

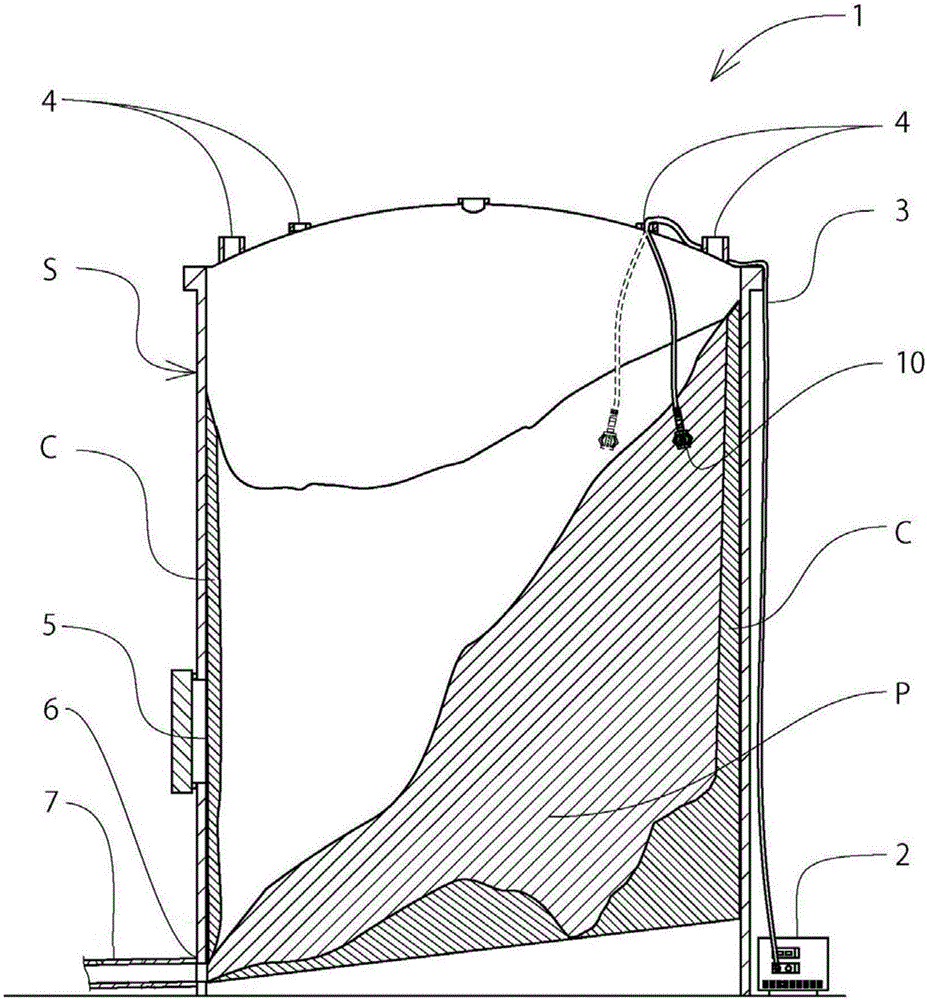

[0058] Embodiment 3 warehouse clearing device

[0059] figure 1 Shown clearing device 1 is a kind of embodiment of the present invention, and the clearing device of this embodiment is mainly the clearing device that hits and clears caking C in material storage S, is by the compression that is arranged outside material storage S The air supply source 2, the storage deblocking tool 10 for beating and removing the agglomeration in the material storage S, and the hose 3 for supplying compressed air from the compressed air supply source 2 to the agglomeration tool 10 are constituted.

[0060] First, the compressed air supply source 2 used by the warehouse clearing device 1 is arranged at a predetermined position. The compressed air supply source 2 arranged outside the material storage S in this embodiment is a large air compressor 21 . The air compressor 21 can be placed on the open space around the material storage S, and no special stand or the like is required. One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com