Zinc pollution construction waste detergent

A construction waste and detergent technology, which is applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., and can solve the problems such as ineffective treatment of zinc element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

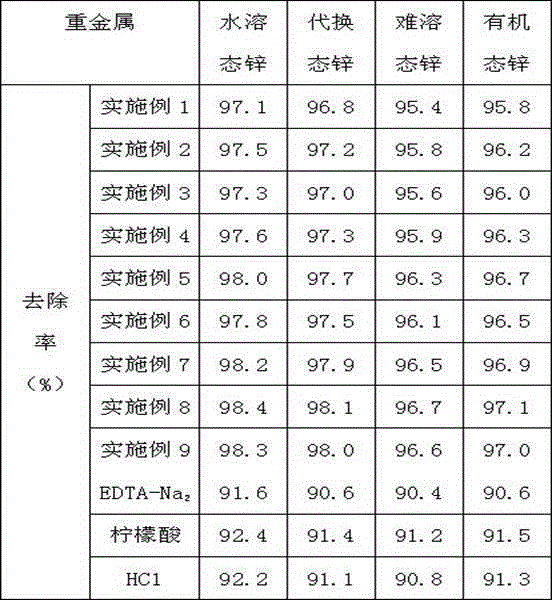

Examples

Embodiment 1

[0040] Weigh the following raw materials in parts by weight: 18kg of methyl heptadecyl ketone, 35kg of 1-methyl-4-(1-methylethylene)cyclohexane-1-ol, 2,2-di Methyl-1,3-propanediyl diacrylate 14kg, 3alpha,7beta-dihydroxy-5beta-cholestane-24-oic acid 24kg, 5-[(3,5-dimethylphenoxy)methyl ] Oxazolidin-2-one 37kg, 2-methyl-2-adamantanol 18kg, propylene glycol dimethyl ether 22kg, 1-cyclohexyl-2-pyrrolidone 30kg, trishydrochloride 14kg.

[0041] The preparation method of the detergent for zinc-contaminated construction waste in this embodiment: deionized water, methyl heptadecyl ketone, 1-methyl-4-(1-methylethylidene) cyclohexane-1- alcohol, 2,2-dimethyl-1,3-propanediyl diacrylate, 3alpha,7beta-dihydroxy-5beta-cholestane-24-oic acid, 5-[(3,5-dimethylbenzene Oxy)methyl]oxazolidin-2-one was added into Reactor 1 and stirred and dissolved at 60-85°C, and 2-methyl-2-adamantanol, propylene glycol dimethyl ether, 1-cyclohexyl-2 -Pyrrolidone and Trishydrochloride are stirred and dissolved...

Embodiment 2

[0043] Weigh the raw materials of the following proportions by weight: 22 kg of methyl heptadecyl ketone, 38 kg of 1-methyl-4-(1-methylethylene) cyclohexane-1-ol, 2,2-di Methyl-1,3-propanediyl diacrylate 8kg, 3alpha,7beta-dihydroxy-5beta-cholestane-24-oic acid 28kg, 5-[(3,5-dimethylphenoxy)methyl ] Oxazolidin-2-one 40kg, 2-methyl-2-adamantanol 12kg, propylene glycol dimethyl ether 25kg, 1-cyclohexyl-2-pyrrolidone 33kg, trishydrochloride 6kg.

[0044] The preparation method of the detergent for zinc-contaminated construction waste in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0046] Weigh the following raw materials in parts by weight: 26 kg of methyl heptadecyl ketone, 32 kg of 1-methyl-4-(1-methylethylene) cyclohexane-1-ol, 2,2-di Methyl-1,3-propanediyl diacrylate 11kg, 3alpha,7beta-dihydroxy-5beta-cholestane-24-oic acid 32kg, 5-[(3,5-dimethylphenoxy)methyl ] Oxazolidin-2-one 34kg, 2-methyl-2-adamantanol 15kg, propylene glycol dimethyl ether 28kg, 1-cyclohexyl-2-pyrrolidone 27kg, trishydrochloride 10kg.

[0047] The preparation method of the detergent for zinc-contaminated construction waste in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com