Method for preparing diglyceride from crude fish oil of marine aquatic fishes

A technology of marine aquatic products and diglycerides, which is applied in the direction of fermentation to achieve the effect of increasing utilization value, creating economic and social benefits, and promoting synthesis research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) the crude fish oil raw material of anchovy, mackerel and glycerin are mixed evenly, and the mol ratio of the substrate in this crude fish oil raw material and glycerin is 1:2.5;

[0026] (2) Add 0.5% immobilized lipase LipozymeRMIM to the material of step (1), and react at a temperature of 52° C. for 8 hours at a stirring rate of 150 r / min;

[0027] (3) After the reaction, the material in step (2) is filtered or centrifuged to remove the immobilized lipase LipozymeRMIM to obtain a mixture containing diglyceride;

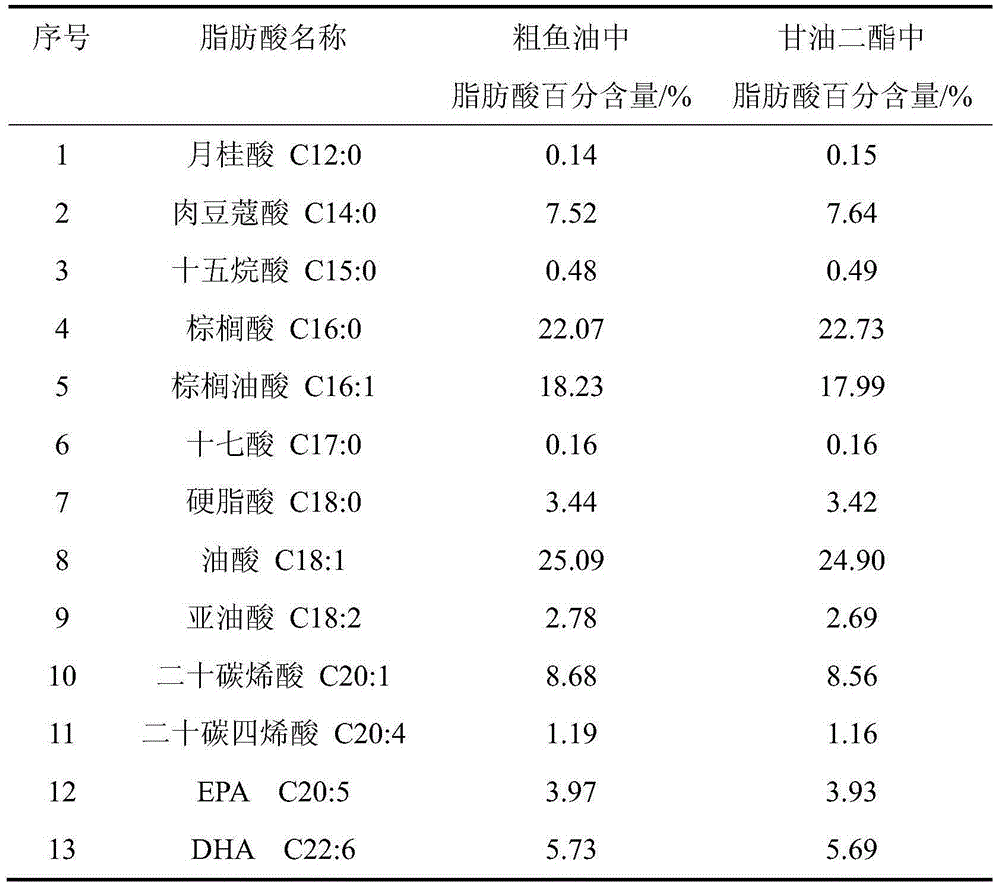

[0028] (4) Molecular distillation or silica gel chromatography is carried out to the mixture obtained in step (3) to obtain a diglyceride product rich in n-3PUFA, and the diglyceride synthesis rate is 45%, wherein the crude fish oil in the present embodiment and the obtained The composition of fatty acids in diglyceride products is shown in the table below:

[0029]

Embodiment 2

[0031] (1) the crude fish oil raw material of anchovy, mackerel and glycerin are mixed evenly, and the mol ratio of the substrate in this crude fish oil raw material and glycerin is 1:2.5;

[0032] (2) Add 0.7% immobilized lipase LipozymeTLIM to the material of step (1), and react at a temperature of 50° C. for 8 hours at a stirring rate of 160 r / min;

[0033] (3) After the reaction, the material in step (2) is filtered or centrifuged to remove the immobilized lipase LipozymeTLIM to obtain a mixture containing diglyceride;

[0034] (4) Molecular distillation or silica gel chromatography is carried out to the mixture obtained in step (3) to obtain a diglyceride product rich in n-3PUFA, and the diglyceride synthesis rate is 44%, wherein the crude fish oil in the present embodiment and the obtained The comparison of the fatty acid composition in the diglyceride product is basically the same as in the examples.

Embodiment 3

[0036] (1) Mix the crude fish oil raw material of anchovy and mackerel with glycerin evenly, and the mol ratio of the substrate in this crude fish oil raw material and glycerin is 1:2;

[0037] (2) Add 0.6% immobilized lipase Novozym435 to the material in step (1), and react at a temperature of 40° C. for 6 hours at a stirring rate of 150 r / min;

[0038] (3) After the reaction, the material in step (2) is filtered or centrifuged to remove the immobilized lipase Novozym435 to obtain a mixture containing diglyceride;

[0039] (4) Molecular distillation or silica gel chromatography is carried out to the mixture obtained in step (3) to obtain a diglyceride product rich in n-3PUFA, and the diglyceride synthesis rate is 42%, wherein the crude fish oil in the present embodiment and the obtained The comparison of the fatty acid composition in the diglyceride product is basically the same as in the examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com