Heat exchanger for washing machine

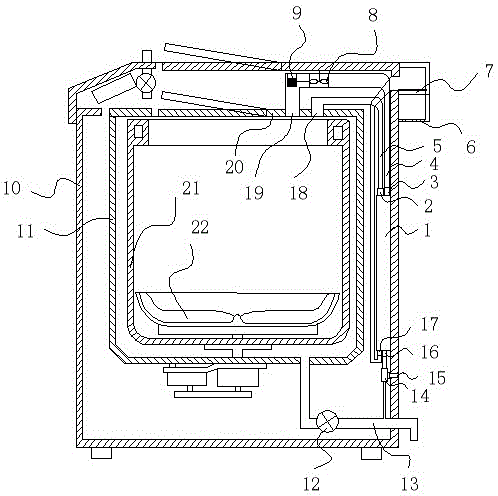

A technology for heat exchangers and washing machines, applied in other washing machines, applications, washing devices, etc., can solve the problems of low utilization rate of heat energy and high power consumption, so as to improve the utilization rate of heat energy, high heat exchange efficiency, and increase flow through effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

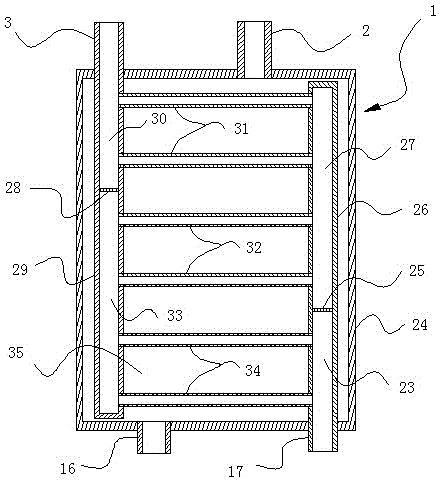

[0016] Such as figure 1 As shown, the heat exchanger 1 of the present embodiment includes a shell 24 and a heat exchange tube, and the heat exchange tube is arranged in the shell 24; the heat exchange tube includes a left vertical pipe 29 and a right vertical pipe 26 and 6 horizontal tubes; the left vertical tube 29 and the right vertical tube 26 are provided with 1 (n=1) partition layers (28, 25), and the left vertical tube 29 and the right vertical tube 26 are from top to bottom The bottom is divided into the first tube space (30, 27) and the second (n+1=2) tube space (33, 23) which are not connected to each other by the one partition layer (28, 25); the horizontal tube The left ends of each are connected with the left vertical pipe 29, and the right ends are connected with the right vertical pipe 26.

[0017] The horizontal tubes are divided into 3 (2*n+1=3) groups; each horizontal tube of the i (i=1, 2, 3 (2*n+1=3)) group of horizontal tubes is connected with all the hori...

Embodiment 2

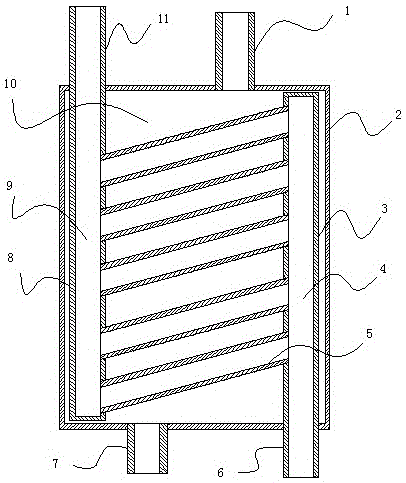

[0025] Such as image 3As shown, this embodiment includes a shell 2 and a heat exchange tube, and the heat exchange tube is arranged in the shell 2 . The heat exchange tubes include a left vertical tube 8 , a right vertical tube 3 and five horizontal tubes 5 . The left vertical pipe 8 and the right vertical pipe 3 are provided with 0 (n=0) partition layers, and the tubes of the left vertical pipe 8 and the right vertical pipe 3 are separated from top to bottom by the 0 partition layers. The first (n+1=1) tube space (9, 4) that is not connected; the left end of the horizontal tube 5 is connected to the left vertical tube 8, and the right end is connected to the right vertical tube 3 .

[0026] The horizontal tubes 5 are divided into 1 (2*n+1=1) groups; each horizontal tube of the i (i=1(2*n+1=1)) group of horizontal tubes is connected to the left vertical tube The xth pipe space of the pipe 8 and the yth pipe space of the right vertical pipe 3 are connected, wherein x is a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com