Semi-submersible type perforated plate plant wave-breaking device

A perforated plate, semi-submersible technology, applied in water conservancy projects, marine engineering, construction, etc., can solve the problems of lack of wave elimination and protection of bank slopes, failure to consider the impact of ecological environment, and fluctuations of ecological floating beds, etc. Simple, good applicability and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

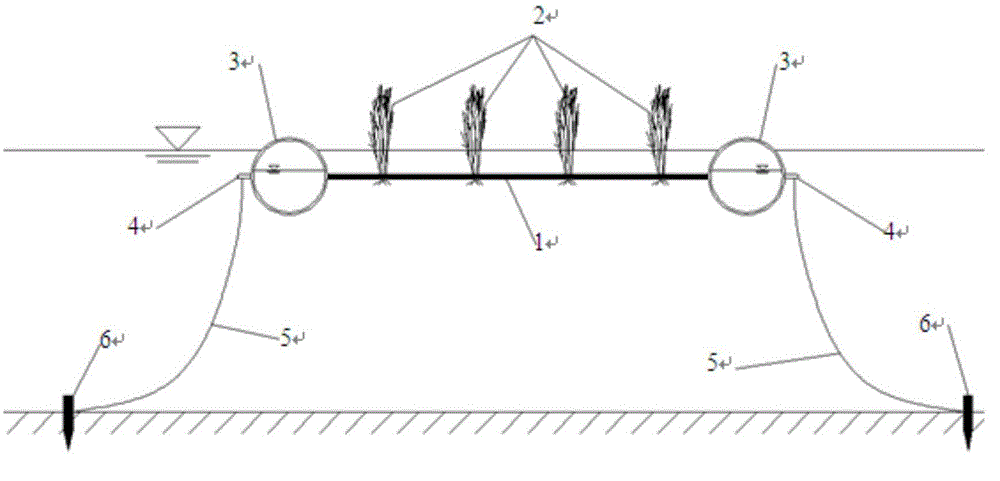

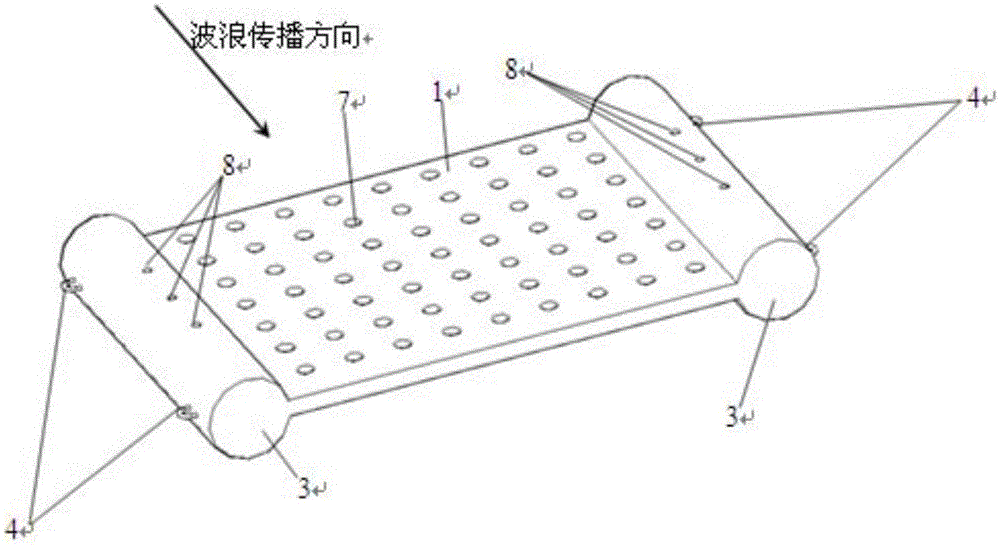

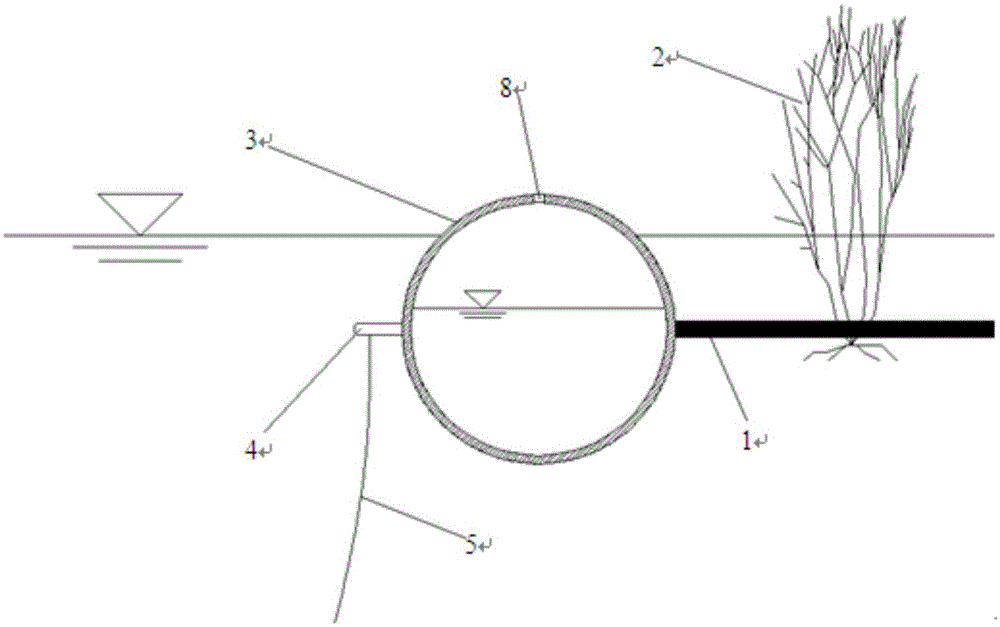

[0030] The present invention is a semi-submersible perforated plate plant wave dissipation device, the specific structure is as follows Figure 1 ~ Figure 4 As shown, it includes a porous plate 1 , aquatic plants 2 , a buoy 3 and a positioning unit. The positioning unit includes an anchor chain 5 and a positioning pile 6 , and is connected to the buoy 3 through a hanging ring 4 .

[0031] Perforated plate 1 is the bigger ABS plastic plate of rigidity, long 100cm, wide 75cm, evenly offers the through hole 7 of interval 12cm on the plate, is used as planting hole and air hole of plant, and aperture is 20mm. Aquatic plants 2 are selected to grow vigorously and have a suitable height, and they are planted in the through holes 7 on the perforated plate 1 at intervals of 24 cm in the length and width directions, and the corresponding planting density is about 18 plants / m 2 .

[0032] The buoy 3 is made of PVC material with a length of 75 cm and is installed on the two short sides of...

Embodiment 2

[0036] A plurality of wave dissipation components are connected end to end through hanging rings and anchor chains to form a chain wave dissipation device. The anchor chains 5 on the wave dissipation components at both ends of the head and tail are respectively fixed on the bottom of the water through positioning piles 6, and the rest of the wave dissipation components are connected with the Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com