High-pressure flat gate valve valve-seat support ring meeting full-differential-pressure opening requirements

A valve seat support ring, flat gate valve technology, applied in the directions of sliding valves, valve devices, engine components, etc., can solve the problems of complex processing shape of the combined valve seat support ring, increase the manufacturing cost, increase the size of the valve body, etc. Simple, increase manufacturing cost, guarantee sealing performance and longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

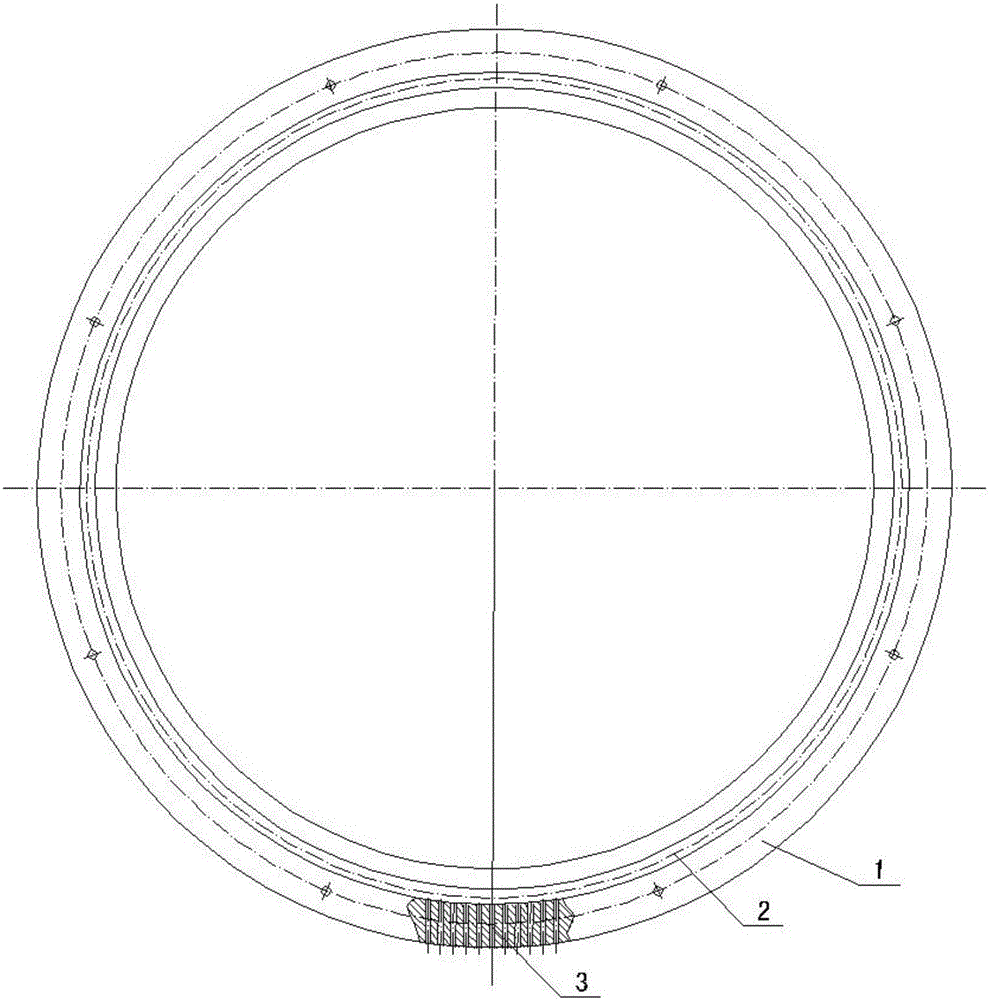

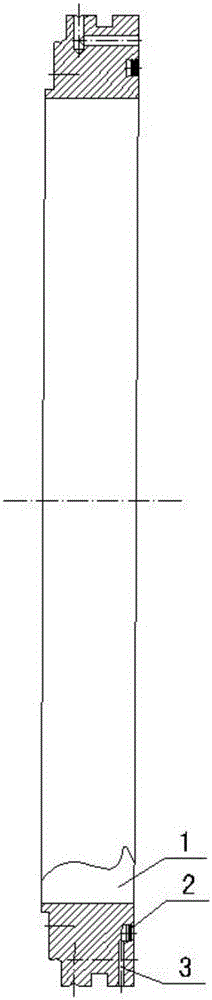

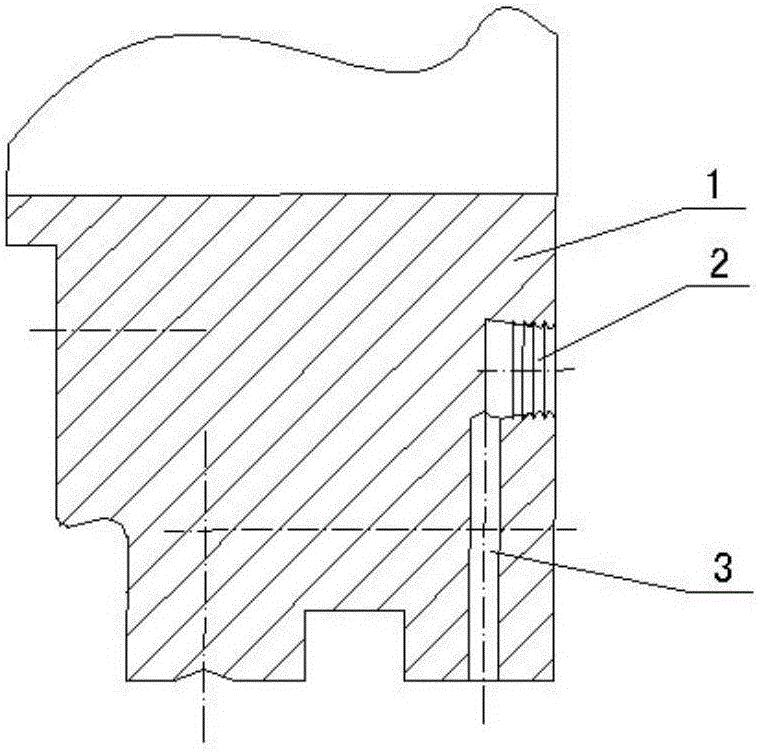

[0024] see figure 1 and figure 2 In this embodiment, the valve seat support ring 1 refers to the ring member used to fix the valve seat in the flat gate valve. An annular groove 2 is provided on one end surface of the valve seat support ring 1, and the valve seat as a seal is installed on the in ring groove 2.

[0025] Such as figure 1 and figure 2 As shown, in this embodiment, a balance hole 3 is provided on the valve seat support ring 1, the center line of the balance hole 3 is located in the plane where the bottom surface of the ring groove 2 is located, and one end of the balance hole 3 starts from the outer ring surface of the ring groove 2, The other end penetrates the outer circumferential surface of the valve seat support ring 1 to form an exhaust passage.

[0026] In specific implementation, the corresponding structural settings also include:

[0027] The balance hole 3 is a single hole or a plurality of holes arranged at intervals at the bottommost position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com