Detection method of carbon-encapsulated material for carbon source

A technology of carbon cladding material and detection method, applied in the direction of material analysis using measurement of secondary emissions, preparation of test samples, etc., can solve problems such as defective products and process fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

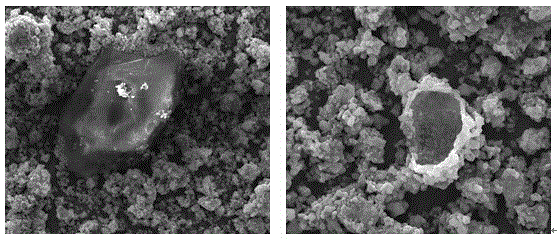

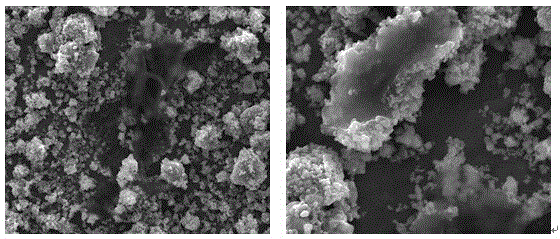

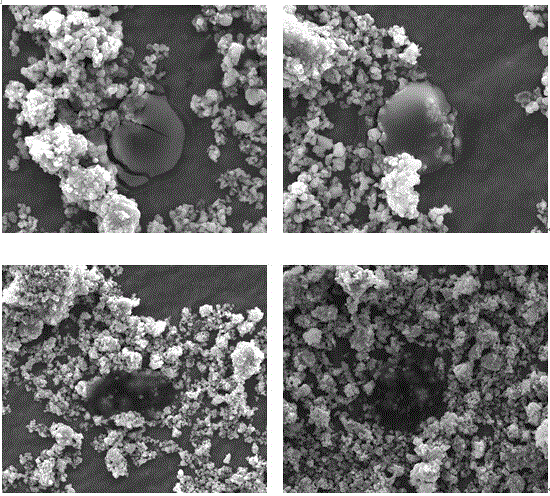

Image

Examples

Embodiment 1

[0017] A method for detecting the carbon source of a carbon-coated material, the detection is completed through the following steps, and the specific steps are as follows:

[0018] (1) Put the carbon-coated material and pure water in a beaker, and then place the beaker on a heating furnace to heat until it boils. The entire boiling process lasts for 4 minutes, and the mass ratio of the carbon-coated material to pure water is 1:10, the mass of carbon-coated material is 4g, and the mass of pure water is 40g;

[0019] (2) Seal the beaker with samples obtained in step (1) with clean aluminum foil, place it in an environment free from chemical pollution, and cool it down to 20-25°C. The samples in the beaker are divided into upper, middle and lower parts. layer;

[0020] (3) The sample obtained in step (2) is layered, and the uppermost floating substance is stuck on a clean aluminum foil with aluminum foil, and the aluminum foil is placed in a vacuum drying oven to dry for 2 hours...

Embodiment 2

[0024] A method for detecting the carbon source of a carbon-coated material, the detection is completed through the following steps, and the specific steps are as follows:

[0025] (1) Put the carbon-coated material and pure water in a beaker, and then place the beaker on a heating furnace to heat until it boils. The entire boiling process lasts for 5 minutes, and the mass ratio of the carbon-coated material to pure water is 1:10, the mass of carbon-coated material is 6g, and the mass of pure water is 60g;

[0026] (2) Seal the beaker with samples obtained in step (1) with clean aluminum foil, place it in an environment free from chemical pollution, and cool it down to 20-25°C. The samples in the beaker are divided into upper, middle and lower parts. layer;

[0027] (3) The sample obtained in step (2) is layered, and the uppermost floating substance is stuck on a clean aluminum foil with aluminum foil, and the aluminum foil is placed in a vacuum drying oven to dry for 2 hours...

Embodiment 3

[0031] A method for detecting the carbon source of a carbon-coated material, the detection is completed through the following steps, and the specific steps are as follows:

[0032] (1) Put the carbon-coated material and pure water in a beaker, and then place the beaker on a heating furnace to heat until boiling. The duration of the entire boiling process is 4.5 minutes. The mass ratio of the carbon-coated material to pure water is The ratio is 1:10, the mass of carbon-coated material is 5g, and the mass of pure water is 50g;

[0033] (2) Seal the sample obtained in step (1) with clean aluminum foil, place it in an environment free from chemical pollution, and cool it to 20-25°C. The sample in the beaker is divided into upper, middle and lower layers;

[0034] (3) For the beaker with the sample obtained in step (2), use aluminum foil to stick the floating substance on the top layer to the clean aluminum foil, and place the aluminum foil in a vacuum drying oven to dry for 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com