Motor performance testing equipment and testing method thereof

A technology for testing equipment and performance, applied in the direction of motor generator testing, testing dielectric strength, etc., can solve the problems of not being able to meet the production needs of motor shafts, unable to perform spark withstand voltage testing, and cumbersome motor performance testing procedures, so as to benefit workers Physical health and safety, improving quality containment capabilities, and solving the effects of low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

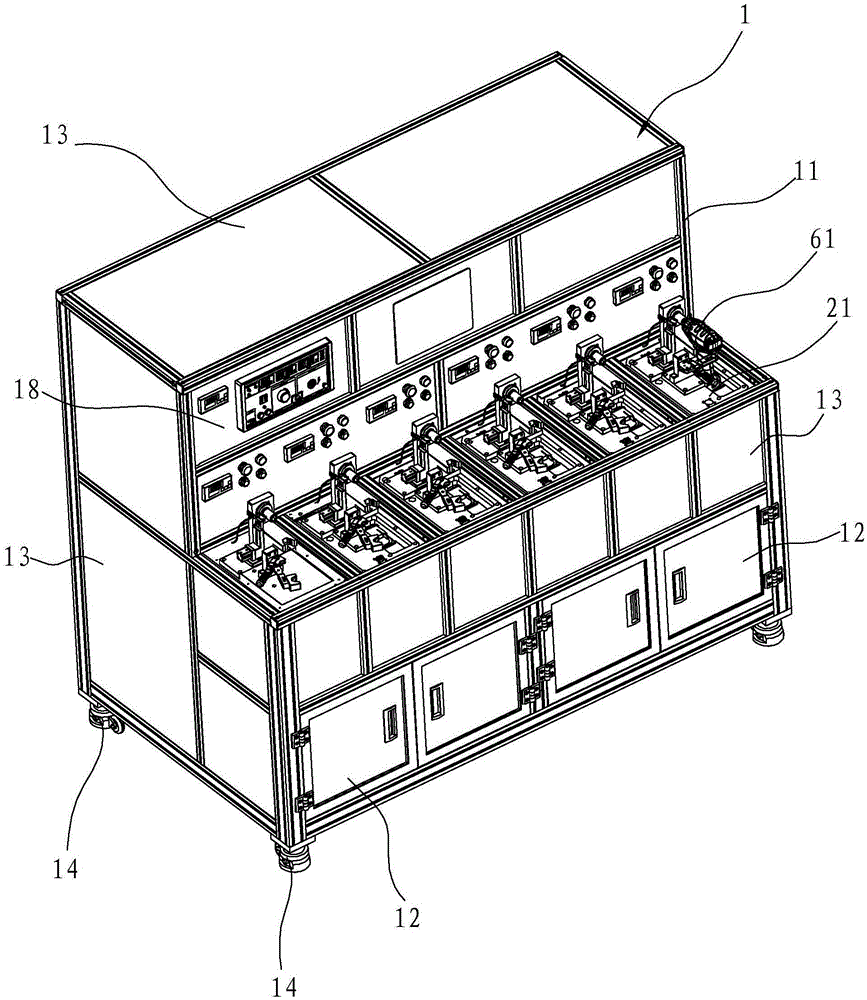

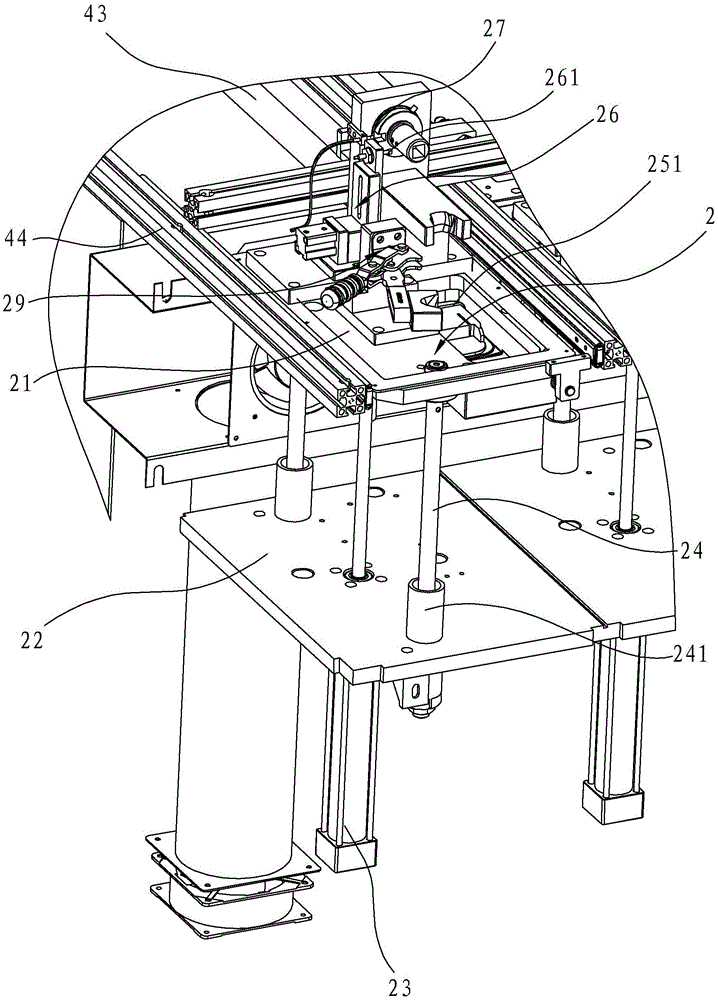

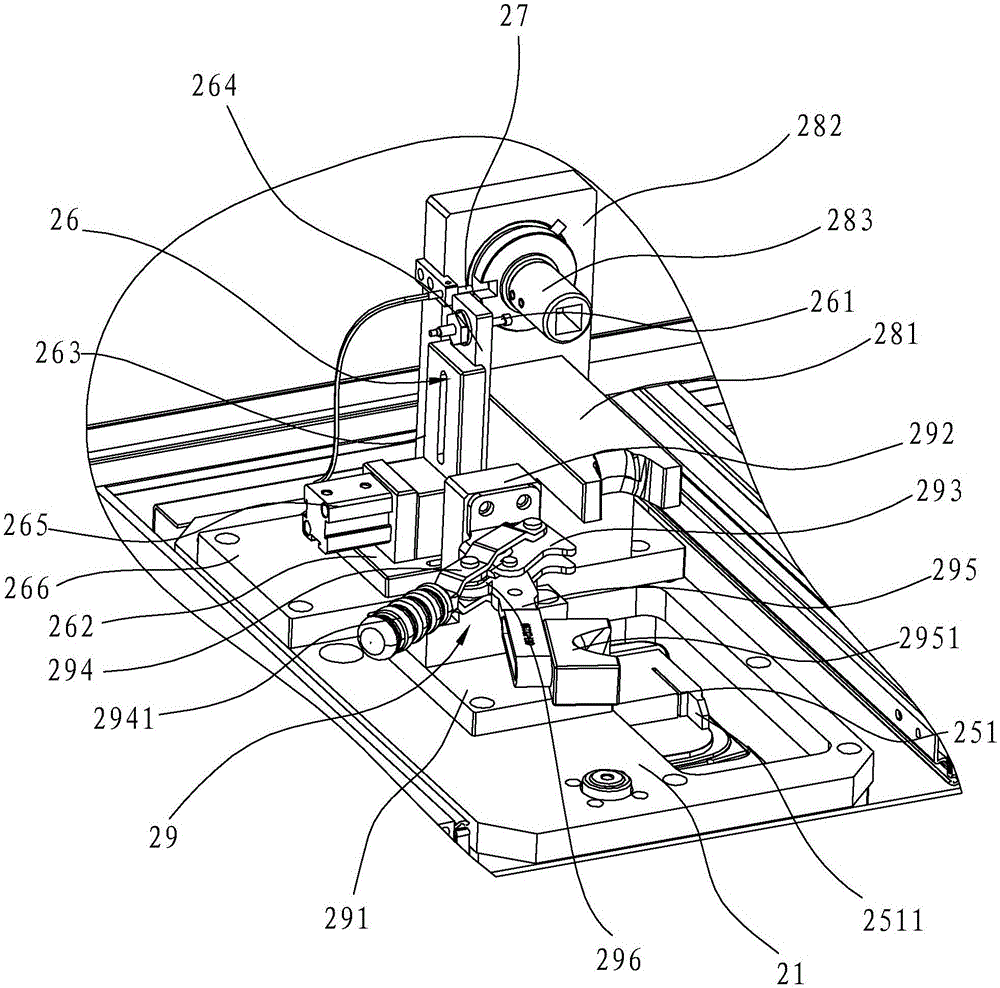

[0046] Such as Figures 1 to 17 As shown, the present invention discloses a motor performance testing device, which includes a frame 1, a testing unit 2, a safety protection mechanism 4, an exhaust cooling mechanism 3 and a control system.

[0047] Among them, such as Figures 5 to 9 As shown, the frame 1 is formed by lapping profiles 11. The frame 1 has a plurality of adjacent detection cabins 15 with openings above. In this embodiment, the number of the detection cabins 15 is 6. The rear side of adjacent detection cabin 15 is formed with control cabinet storage case 16, is provided with control system in the control cabinet storage case 16, and this control system realizes the automatic control of motor performance testing equipment, and this control system has the positive motor rotation of driving detection product. Negative power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com