Intelligent numerical control machine tool and system

A technology of CNC machine tools and CNC lathes, which is applied in the fields of digital control, manipulator, electrical program control, etc., can solve the problem that patents cannot be measured, and achieve the effect of reducing labor intensity, operation preparation time, and saving training costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

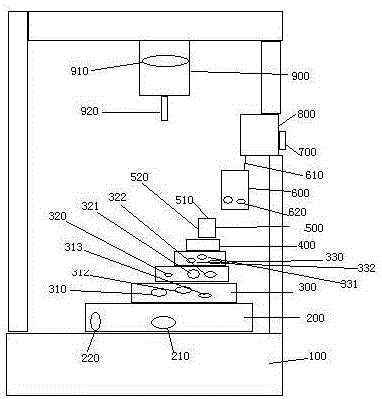

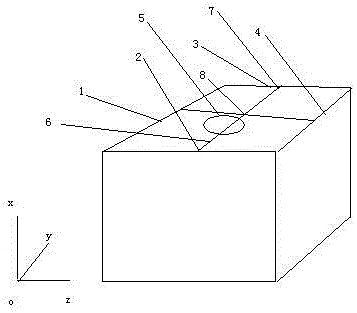

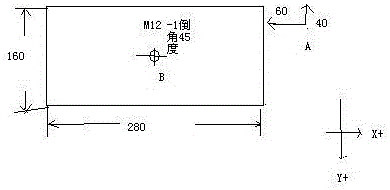

[0023] See Figure 1 to Figure 5 , which are the numerically controlled machine tools and systems provided by the embodiments of the present invention. In this embodiment, the CNC machine tool is a vertical machining center. The CNC machine tool and system includes a monitoring device 700, an input device 620, a display device 600, an indexing device 300, a work platform 200, a spindle 900, a tool 920, a controller 800, a Z-axis servo device 910, an X-axis servo device 220, Y-axis servo 210 . The monitoring device 700 , the input device 620 , the display device 600 , the indexing device 300 , the work platform 200 , the spindle 900 , the tool 920 , the controller 800 , the Z-axis servo device 910 , the X-axis servo device 220 , and the Y-axis servo device 210 Both are mounted on the machine body 100 .

[0024] The indexing device 300 is clamped on the working platform 200, and the workpiece 500 or the fixture 400 that clamps the workpiece 500 is clamped on it. , Y dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com