Representation method of drilling damage to carbon fiber composite

A composite material and carbon fiber technology, used in special data processing applications, instruments, electrical digital data processing, etc., can solve the concomitant generation, without comprehensive consideration of drilling burrs, tearing and delamination damage, unable to accurately characterize the degree of processing damage and other problems, to achieve the effect of accurate results, good engineering application prospects, and simple calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following combines technical solutions and Attached picture The specific implementation of the present invention will be described in detail.

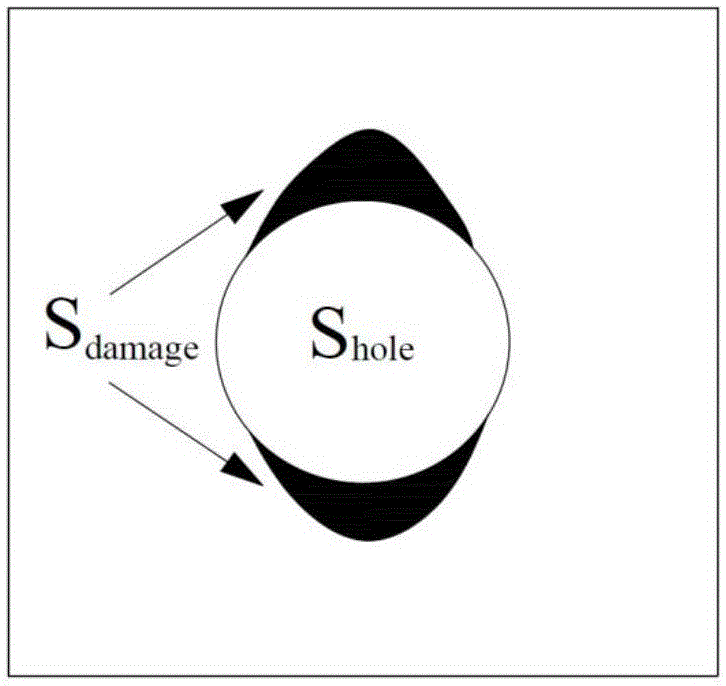

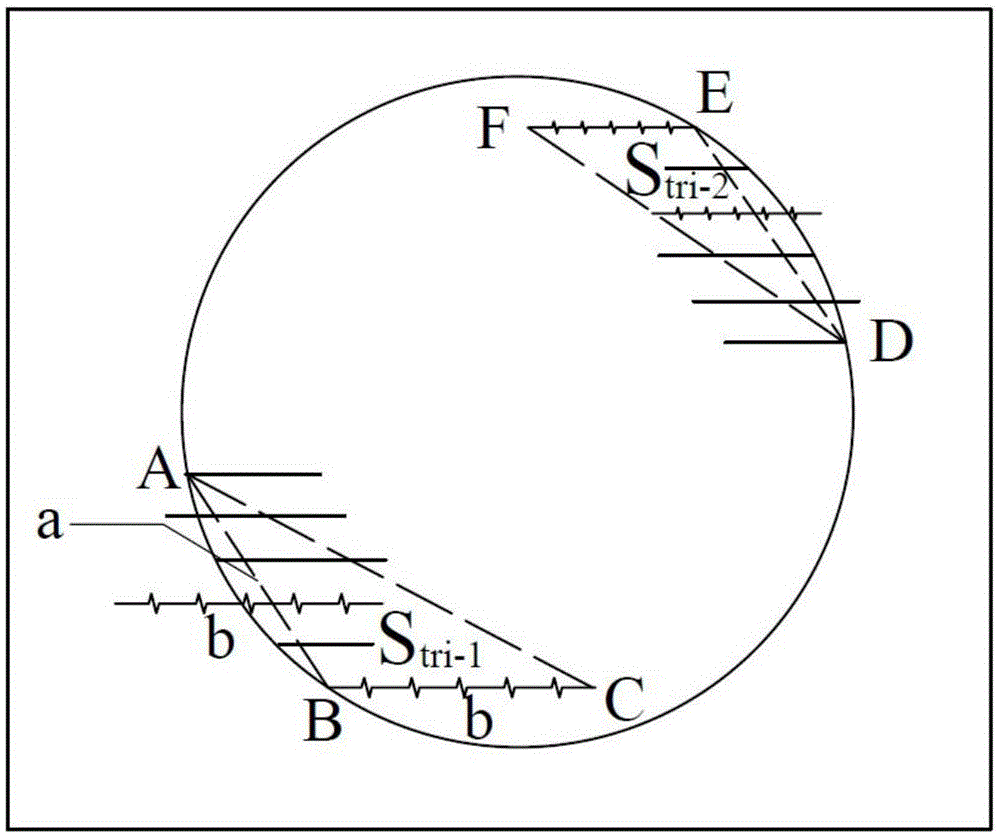

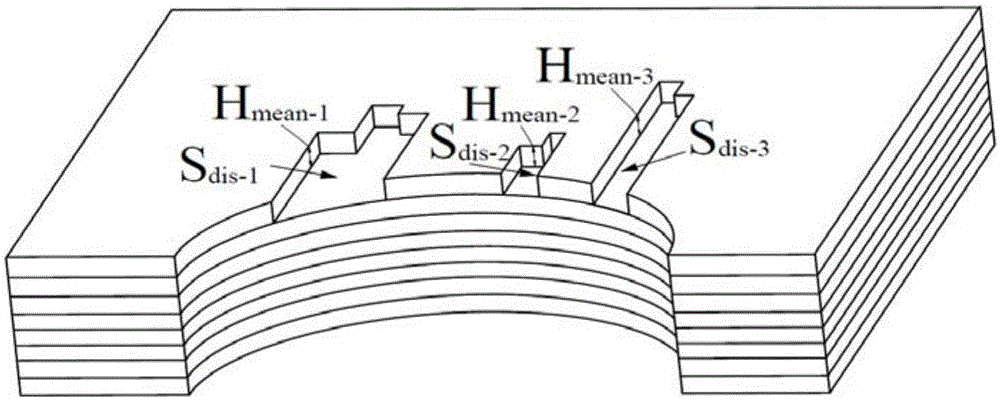

[0028] In this embodiment, the workpiece is a one-way plate made of carbon fiber composite material, and the thickness of the workpiece is 3mm. The drilling experiment uses a cemented carbide drill bit with a diameter of 6mm. The drilling revolution is 2000r / min, and the feed rate is 300mm / min. Since various damages are often accompanied by actual processing, the present invention comprehensively considers the burr, tear and delamination damage caused by drilling, and the influence of the burr generation area, and uses the weight coefficients of the impact of these three types of damage on the performance of the workpiece to derive The damage characterization factor formula, through the establishment of the regression model between the three damage factors of delamination, burr, and tearing, and the mechanical performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com