Epoxy resin cast coil for dry-type transformer

A technology of dry-type transformer and epoxy resin, which is applied in the direction of transformer/inductor coil/winding/connection, etc., and can solve problems affecting the service life of the transformer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Combine below Figure 4 , Figure 5 with Image 6 The present invention is described in further detail.

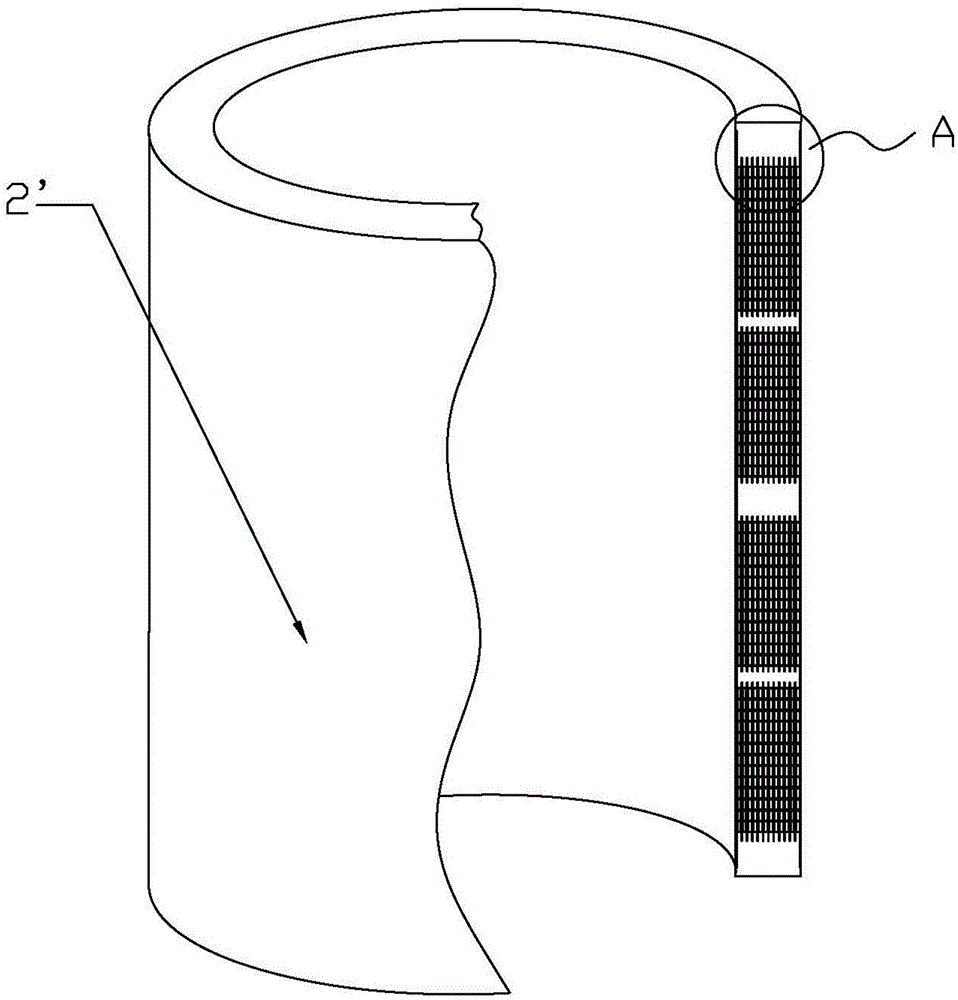

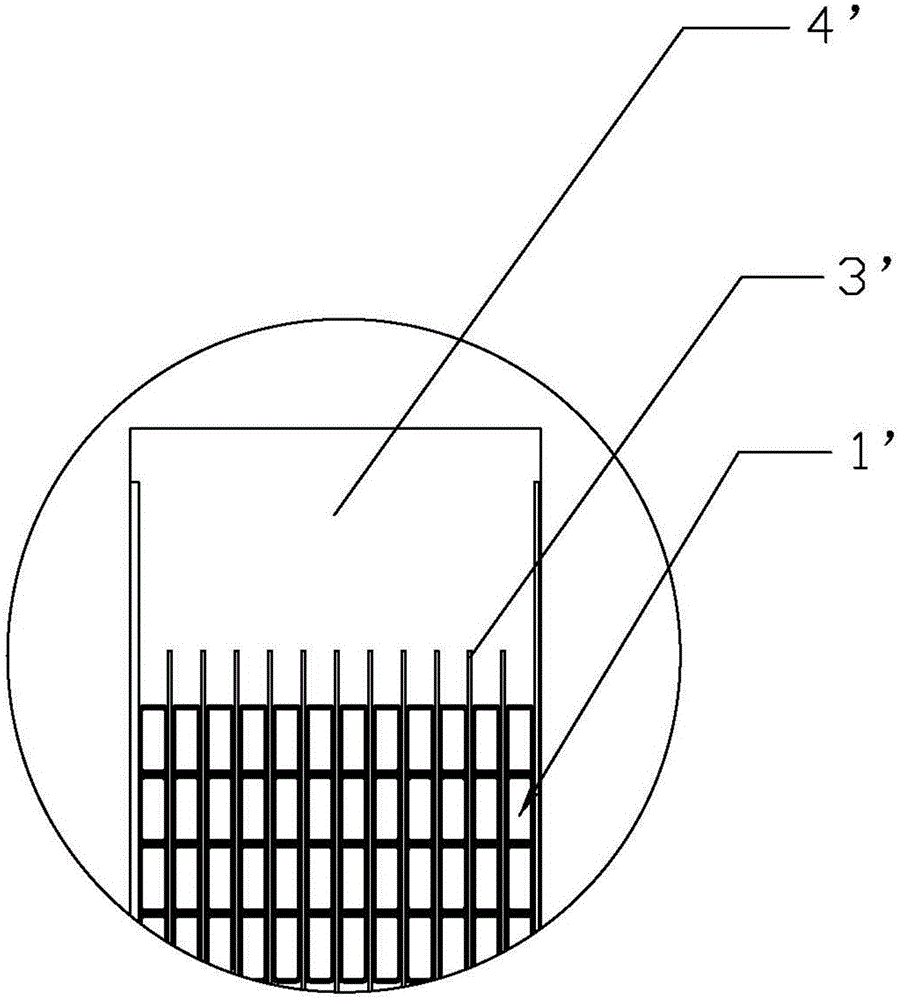

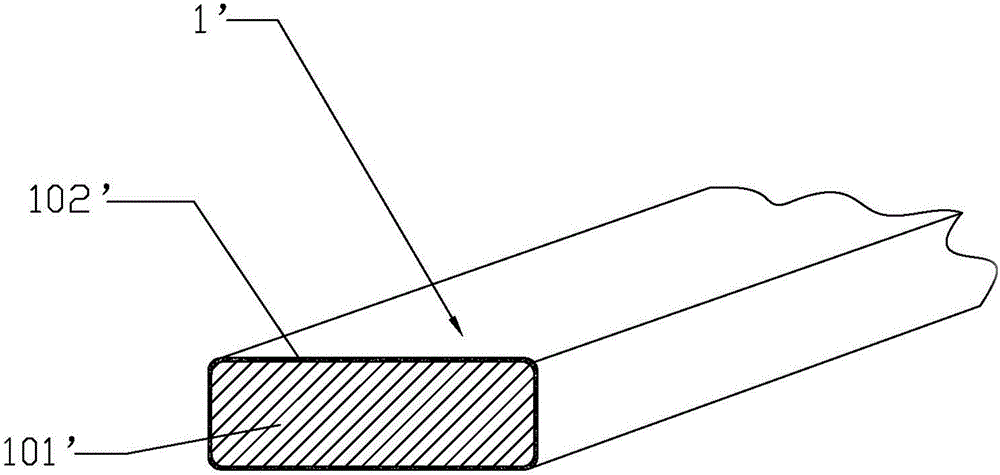

[0022] as attached Figure 4 , the present invention is an epoxy resin cast coil for dry-type transformers, which includes a coil body 2 that is formed by winding a wire 1 into a multi-layer structure and pouring epoxy resin 4; as attached Image 6 As shown, the wire 1 includes a conductive body 101 and a glass fiber strip 102 wound and fixed on the outer peripheral surface of the conductive body 101 in a helical form; the adjacent glass fiber strips 102 on the conductive body 101 are arranged at intervals; wherein the adjacent glass fibers The separation distance between the strips 102 is 2-3mm. Among them, the glass fiber strips 102 are wound and fixed on the conductive body 101 in a helical form, and the distance between adjacent glass fiber strips 102 is 2-3mm. The finished coil 2 for the dry-type transformer, when performing the casting epoxy resin process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com