Novel high-gain printed quasi-yagi antenna

A high-gain, quasi-Yagi technology, applied in the direction of antennas, electrical components, etc., can solve the problem of small gain of quasi-Yagi antennas, and achieve the effect of good matching, high gain, and good radiation enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

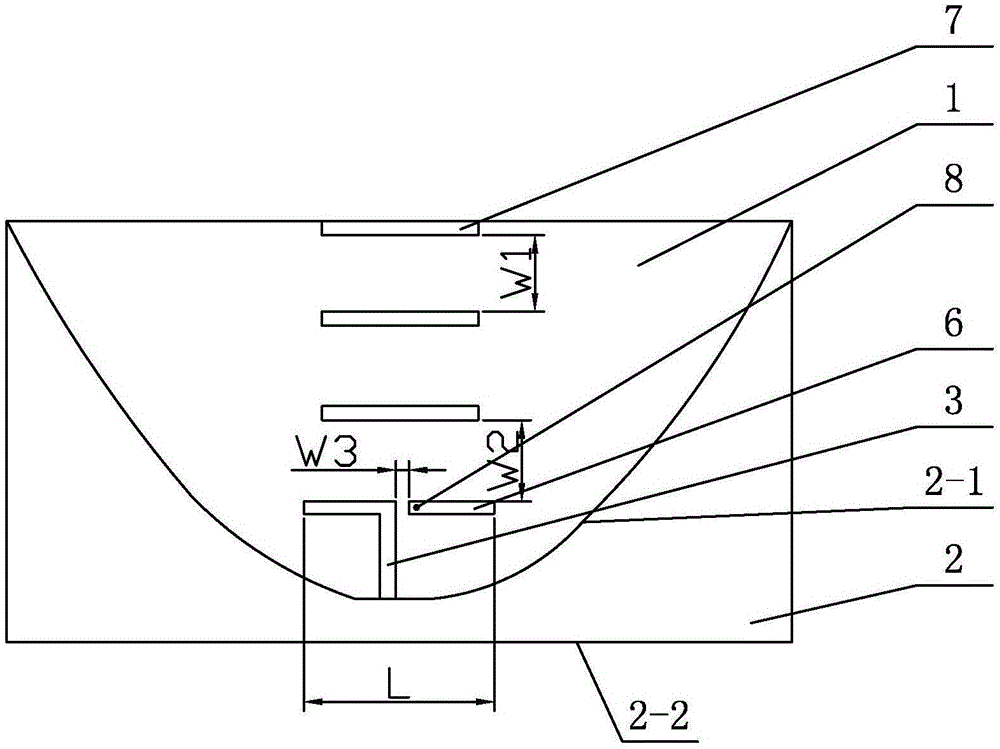

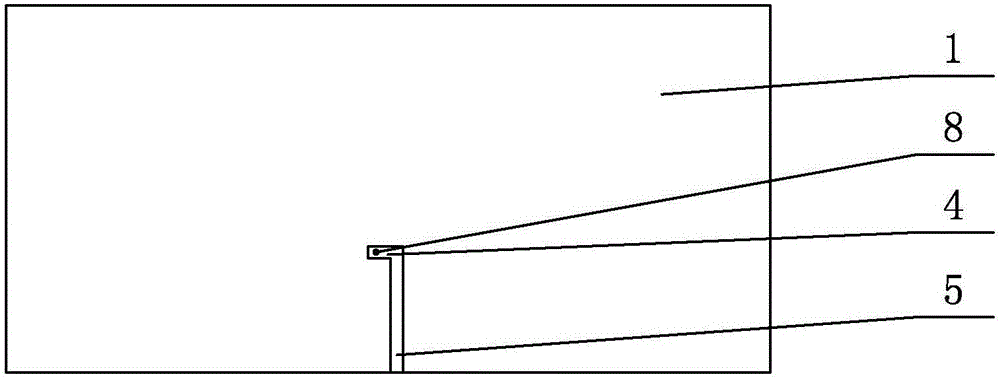

[0007] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, a new type of high-gain printed quasi-Yagi antenna described in this embodiment includes a dielectric substrate 1, a reflector 2, a front elongated feeder 3, a rear rectangular feeder 4, a rear elongated feeder 5, two The source oscillator arm 6 and the three guide oscillators 7, the reflector 2 is printed on the lower part of the front of the dielectric substrate 1, the reflector 2 is a closed metal layer composed of a concave parabolic side 2-1 and a straight line side 2-2, and The straight side 2-2 of the reflector 2 coincides with the bottom edge of the front of the dielectric substrate 1, and the three guiding vibrators 7 are printed sequentially on the upper part of the front of the dielectric substrate 1 from top to bottom, and the two active vibrator arms 6 are in the shape of a line Printed on the middle of the front surface of the dielectric substrate 1, two active...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the length of the dielectric substrate 1 of a novel high-gain printed quasi-Yagi antenna described in this embodiment is 180 mm, the width of the dielectric substrate 1 is 100 mm, and the thickness of the dielectric substrate 1 is 1.6 mm.

[0010] The technical effect of this embodiment is that: with such an arrangement, the impedance and radiation characteristics of the antenna are good. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the length of the straight side 2-2 of the reflector 2 of a novel high-gain printed quasi-Yagi antenna described in this embodiment is 180 mm.

[0012] The technical effect of this embodiment is that: with such an arrangement, the impedance and radiation characteristics of the antenna are good. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com