Method for filling a microfluidic device using a dispensing system and corresponding test system

A technology of microfluidic device and test system, which is applied in measurement devices, fluid controllers, chemical instruments and methods, etc., can solve problems such as unfavorable bedside systems, and achieve the effect of rapid evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

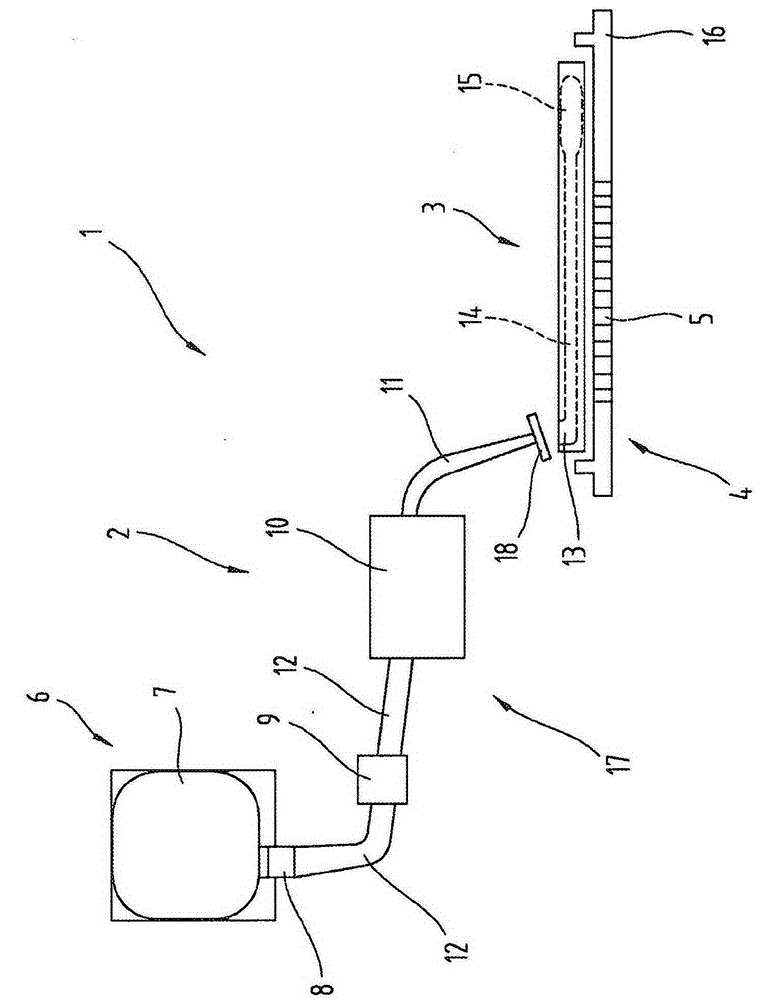

[0057] First of all, it should be noted that in the differently described embodiments, the same parts are provided with the same reference signs or the same component designations, and the disclosure contained in the entire description can be applied to the same reference signs or the same component designations. parts. Position specifications selected in the description, such as top, bottom, side, etc., also refer to the directly illustrated and described figures and, in the event of a change in position, apply sensibly to the new position. In addition, individual features or combinations of features from the various exemplary embodiments shown and described can also form independent, inventive or inventive solutions in themselves.

[0058] All data of numerical ranges in this specification are to be understood in such a way that these numerical ranges also include any and all subranges of these numerical ranges together, for example data 1 to 10 are to be understood in such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com