Method for improving tobacco seed storage durability

A tobacco seed storage technology, which is applied in the field of improving the storage resistance of tobacco seeds, can solve the problems of short storage time, high cost, and poor effect of tobacco seeds, and achieve the benefits of storage, strong antioxidant capacity, and reduced respiratory metabolism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

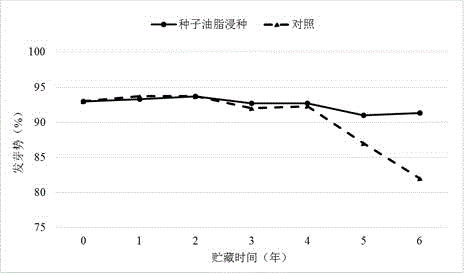

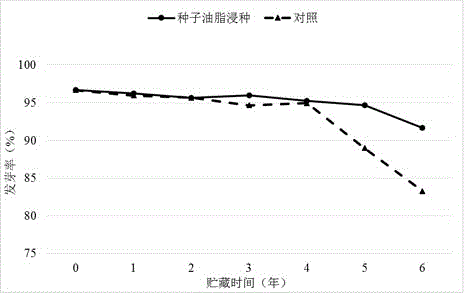

[0021] Take 1Kg of MS Yunyan 87 seeds, immerse in a barrel containing 2Kg of tobacco seed oil, and stir constantly so that each tobacco seed is wrapped by tobacco seed oil. After 2 hours, use a nylon mesh bag with a pore size of 50 mesh to filter the tobacco seeds. Then put it into the washing machine to remove excess tobacco seed oil by centrifugation, transfer it to a cloth bag, and store it in an air-conditioned room with a temperature of 17±1°C and a relative air humidity of 40-45%. Before storage and within 1 year, 2 years, 3 years, 4 years, 5 years, and 6 years, 5g of seeds were taken out, and the standard method specified in YC / T20-1994 "Tobacco Seed Inspection Regulations" was used to determine the germination of the seeds. At the same time, the same batch of tobacco seeds stored under the same conditions that were not soaked in tobacco seed oil were used as a control to conduct experiments.

[0022] Experimental results such as figure 1 and figure 2 shown.

[0023...

Embodiment 2

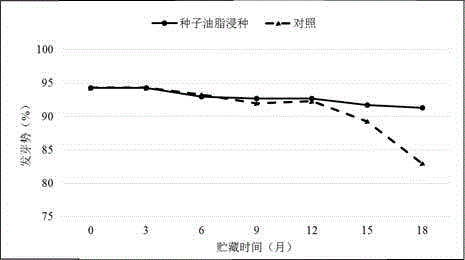

[0025] Repeat application embodiment 1, difference is: the test material selected for use is the MSK326 seed after triggering 24 hours, respectively before storage and storage 3 months, 6 months, 9 months, 12 months, 15 months, 18 months After one month, the germination potential and germination rate of the seeds were measured.

[0026] Experimental results such as image 3 and Figure 4 shown.

[0027] The results showed that the germination potential of the control primed seeds dropped sharply to 83.0% in the 18th month of storage; the germination potential of the primed seeds soaked in tobacco seed oil remained above 90% after 18 months of storage. The germination rate of the control priming seeds decreased rapidly to 86.0% in the 18th month of storage; the germination rate of the priming seeds soaked in tobacco seed oil still reached 92.0% after 18 months of storage. It can be seen that soaking seeds in tobacco seed oil can also improve the storage resistance of tobacco...

Embodiment 3

[0029] The difference between repeating Example 1 and Example 2 is that the selected test material is the original species of safflower dajin yuan, and the storage temperature is 4±1°C.

[0030] Experimental result is identical with embodiment 1 and embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com