Method for detecting air leakage rate of interior of roller in roller processing course for tobaccos to be produced into shreds

A technology of processing process and detection method, applied in the direction of tobacco, tobacco processing, application, etc., can solve the problems of complex processing equipment, difficult to measure air leakage, and achieve the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

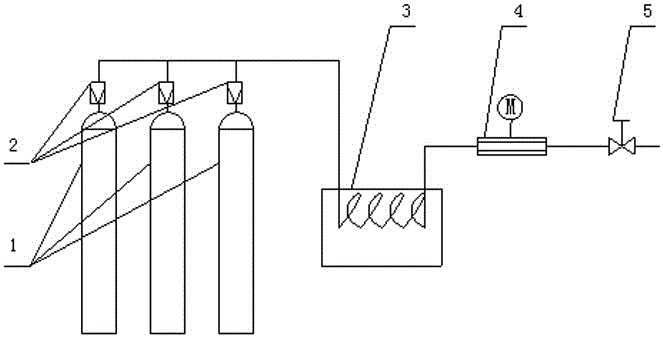

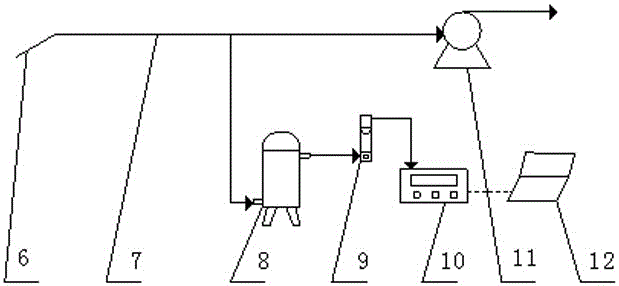

[0032] The detection method of the present invention passes as figure 1 , 2 The device and system shown are completed. The carbon dioxide quantitative injection system includes a carbon dioxide cylinder gas source 1, a pressure reducing device 2, a gas path constant temperature water tank 3, a mass flow controller 4 and an injection stop valve 5. The gas sampling pretreatment system includes a sampling system inlet 6 , an air extraction pipeline 7 , an air extraction pump 11 , a dry filter 8 and a rotameter 9 . The carbon dioxide online detection and analysis system includes a carbon dioxide online detection device 10 and a mobile computer workstation 12 .

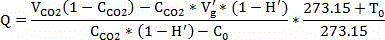

[0033] The method for detecting the amount of air leakage in the cylinder during the processing of the tobacco thread cylinder provided by the present invention has the following impleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com