Bone cement stirring and injecting system

A technology of bone cement and agitator, which is applied in the field of medical devices, can solve problems such as difficulty in operation, potential safety hazards, and easy solidification of bone cement, so as to avoid the invasion of radiation, improve operation efficiency, and save operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

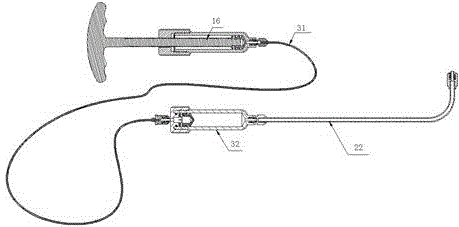

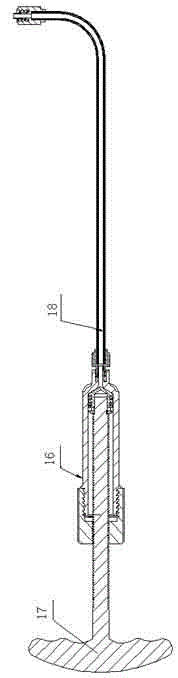

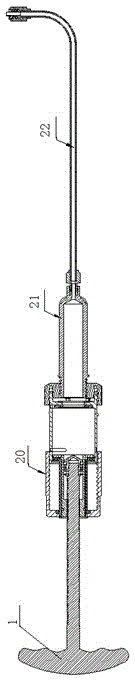

[0041] figure 2 It is the overall structure diagram of the bone cement mixing and injecting system, the system is mainly composed of the screw handle 1, the bone cement mixer 20, the bone cement injection cylinder 21 and the bone cement outlet tube 22; the screw handle 1 and the bone cement mixer 20 are assembled Such as Figure 3-4 as shown, Figure 4 yes image 3 The local enlarged view of the shell assembly 6 and the main container 12 are fixedly connected by multi-threads, the stirring channel part 3 is arranged inside the shell assembly 6, the shell assembly 6 is fixedly connected with the stirring channel part 3, and the stirring movable part 5 is arranged inside the stirring channel part 3, The stirring movable part 5 is slidingly connected with the stirring channel part 3, and an O-ring 4 is set between the stirring movable part 5 and the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com