Electrode for honeycomb processing and preparation method of integral honeycomb

An electrode and honeycomb technology is applied in the field of electrodes and honeycomb preparation using the electrode, and can solve the problems of split brazing honeycomb desoldering, high cost, and difficulty in precision casting of ultra-thin structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

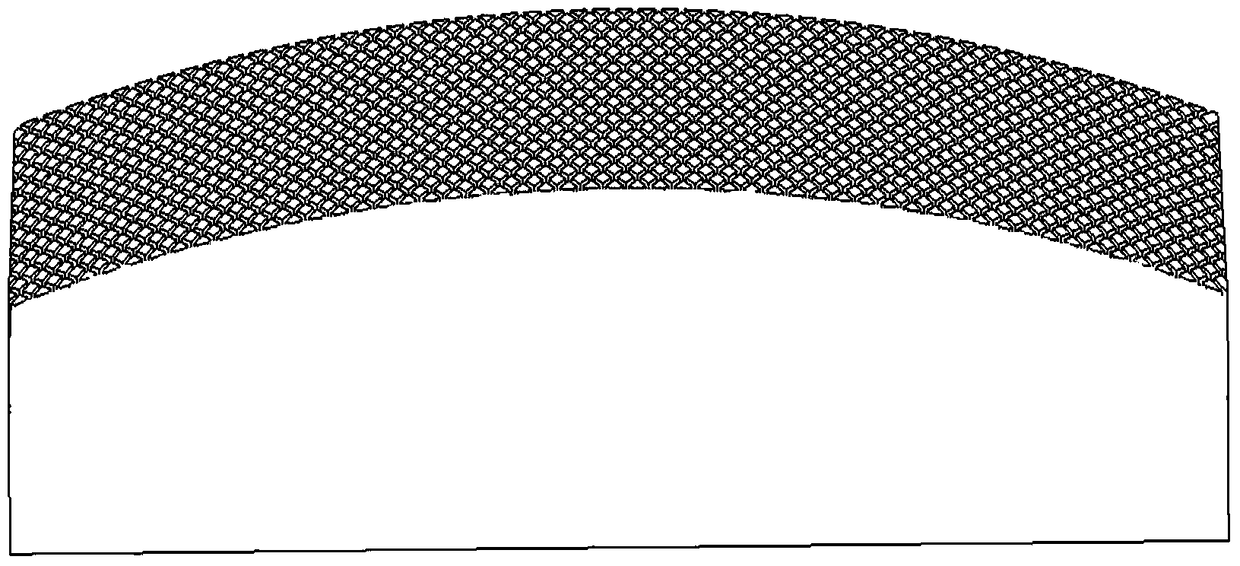

[0021] This embodiment provides an electrode for honeycomb processing and a method for preparing a whole honeycomb for sealing by using the electrode, so that the scheme of integrally processing a honeycomb sealing structure by an electric discharge forming machine is realized.

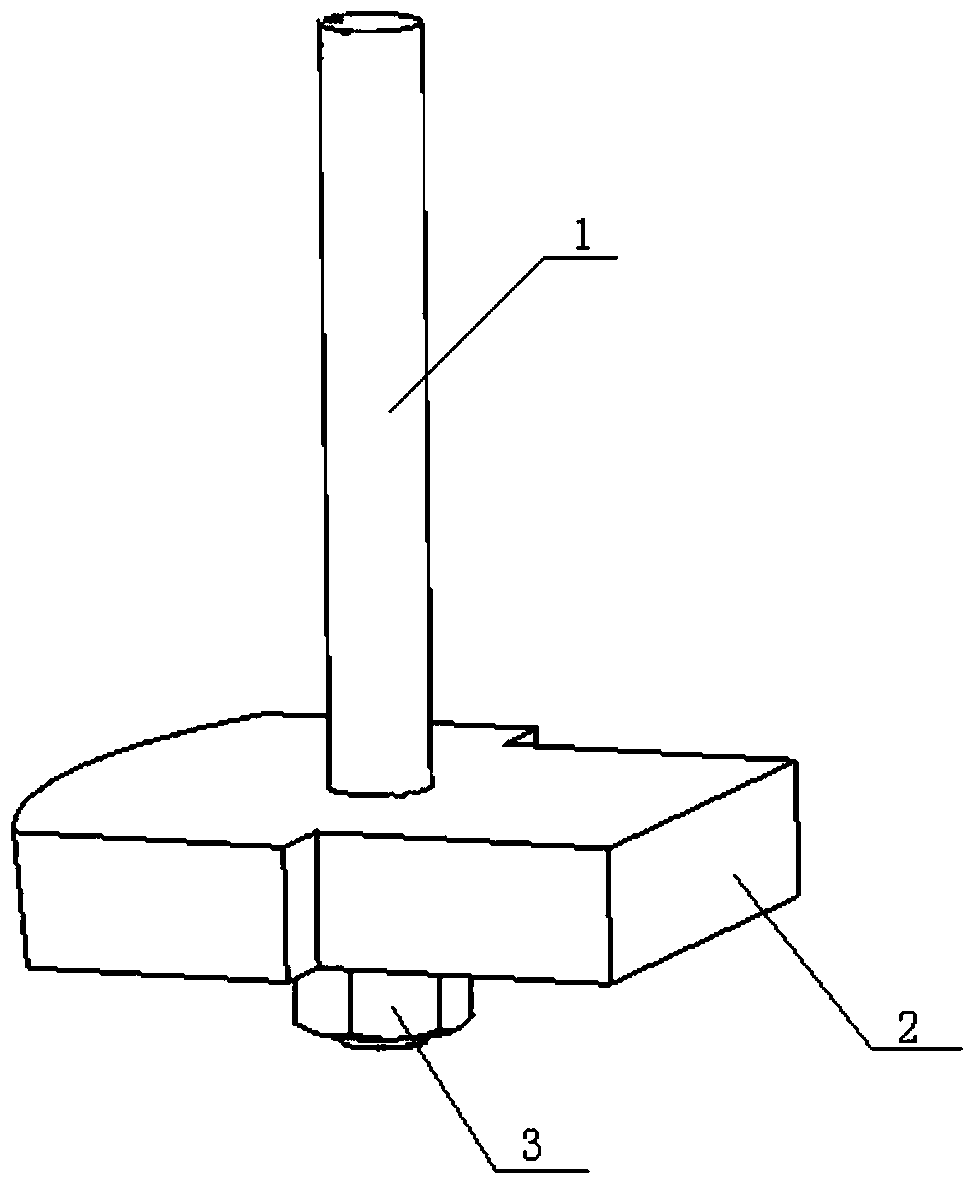

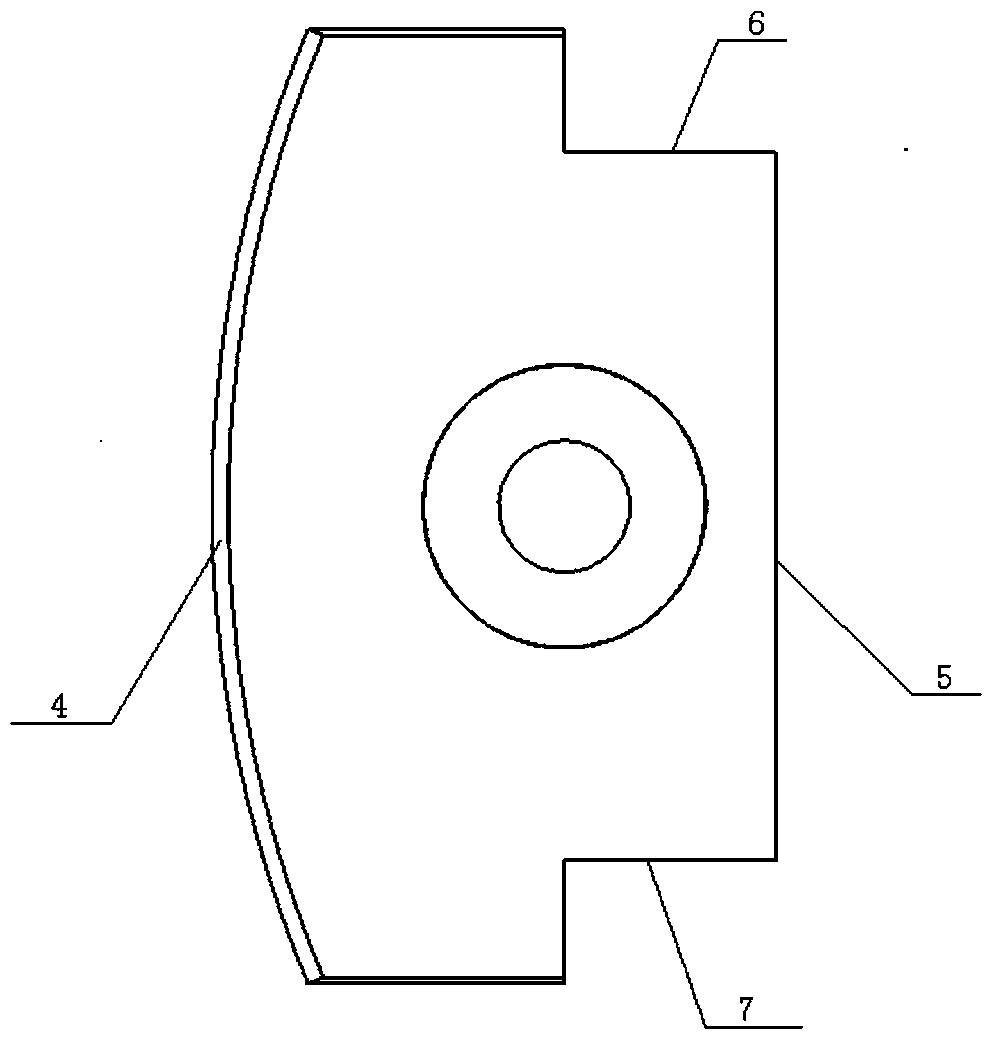

[0022] The electrode is a split structure, including: clamping handle 1, main electrode 2 and locking piece 3, such as figure 1 shown. The clamping handle 1 is a rod-shaped structure made of stainless steel, which can solve the problem of insufficient rigidity of the split electrode. The bottom of the clamping handle 1 protrudes through the mounting holes on the upper and lower end surfaces of the main motor 2 and is locked by the locking member 3 . In order to eliminate the positioning gap, the matching surface of the clamping handle 1 and the mounting hole on the main motor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com