Scissor-type automatic particle packaging machine for material separation protection

An automatic packaging machine, scissor-type technology, applied in the field of scissor-type particle automatic packaging machine, can solve the problems of large gap between the turntable and the material distribution baffle, difficult maintenance and cleaning, and pollution of packaging materials, so as to facilitate disassembly and replacement and internal cleaning , avoid metal particle pollution, reduce the effect of use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

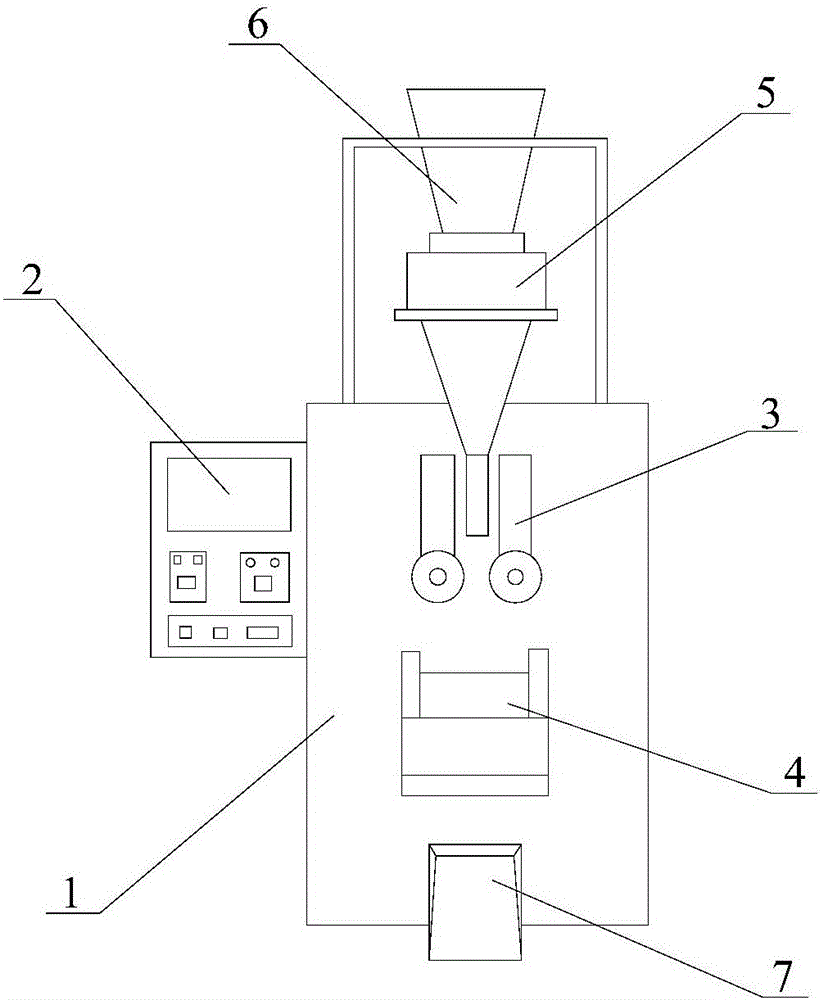

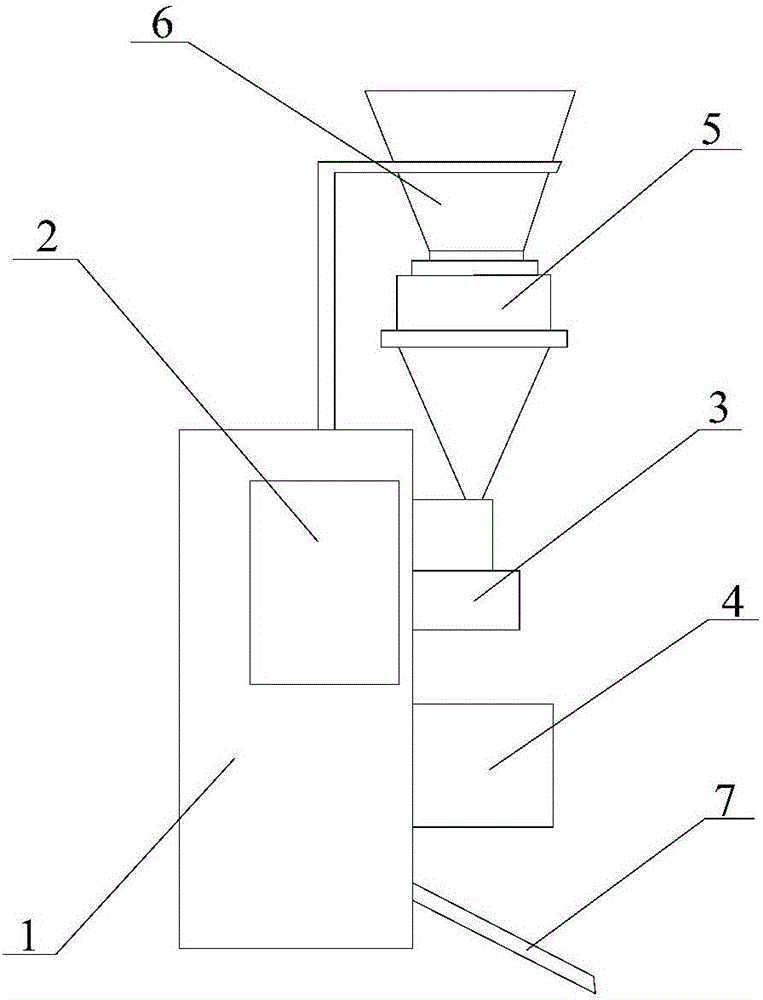

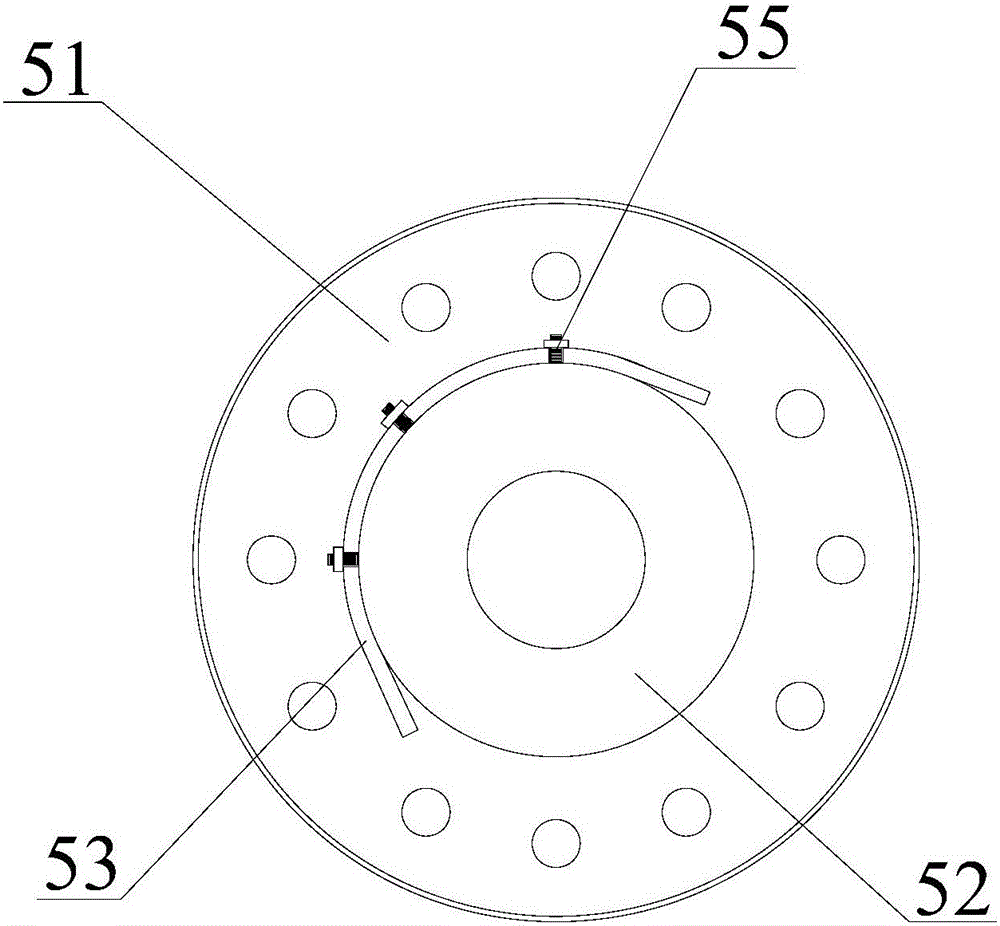

[0014] like Figure 1-4 As shown, an improved scissors-type automatic packaging machine for granules includes a body 1, an automatic control system 2 and a packaging bag former 3, a shearing device 4 and a distributor device 5 arranged on the body 1. A hopper 6 is connected to the feeder device 5 , and the feeder device 5 includes a turntable 51 and a material distribution baffle 52 arranged on the upper part of the turntable 51 . The material distribution baffle 52 is suspended relative to the turntable 51 . A resin blocking piece 53 is arranged on the outer side wall of the material baffle 52 , and the lower edge of the resin blocking piece 53 is attached to the upper surface of the turntable 51 ; the lower part of the shearing device 4 is provided with a downwardly inclined sliding plate 7 .

[0015] The upper end of the resin baffle 53 is provided with a plurality of vertically upward U-shaped installation grooves 54, and the material distribution baffle plate 52 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com